What Tunable Lasers Does the Network Edge Need?

Several applications in the optical network edge would benefit from upgrading from 10G to 100G DWDM or from 100G grey to 100G DWDM optics:

- Business Services could scale enterprise bandwidth beyond single-channel 100G links.

- Fixed Access links could upgrade the uplinks of existing termination devices such as optical line terminals (OLTs) and Converged Cable Access Platforms (CCAPs) from 10G to 100G DWDM.

- Mobile Midhaul benefits from a seamless upgrade of existing links from 10G to 100G DWDM.

- Mobile Backhaul benefits from upgrading their linksto 100G IPoDWDM.

The 100G coherent pluggables for these applications will have very low power consumption (less than 6 Watts) and be deployed in uncontrolled environments. To enable this next generation of coherent pluggables, the next generation of tunable lasers needs enhanced optical and electronic integration, more configurability so that users can optimize their pluggable footprint and power consumption, and the leveraging of electronic ecosystems.

The Past and Future Successes of Increased Integration

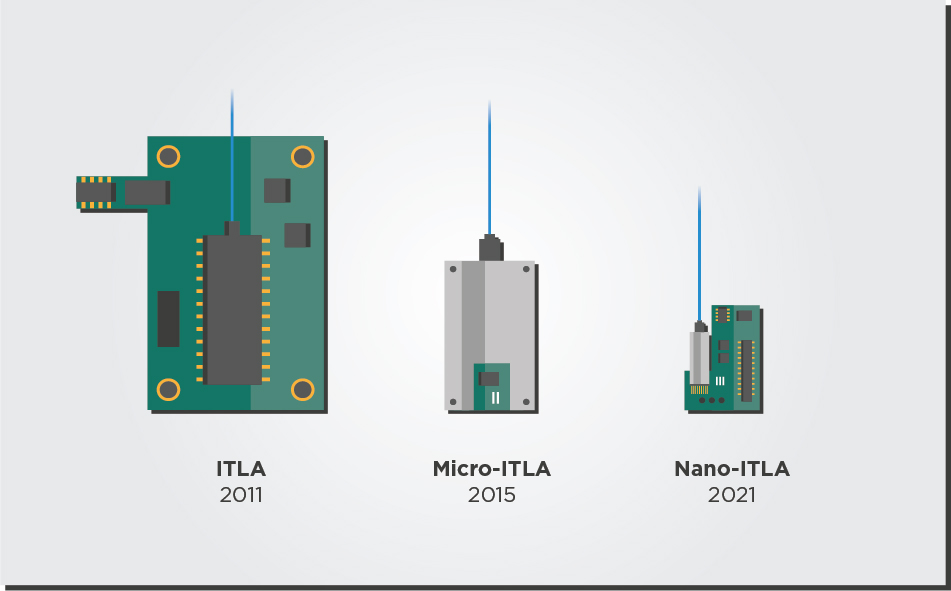

Over the last decade, technological progress in tunable laser packaging and integration has matched the need for smaller footprints. In 2011, tunable lasers followed the multi-source agreement (MSA) for integrable tunable laser assemblies (ITLAs). The ITLA package measured around 30.5 mm in width and 74 mm in length. By 2015, tunable lasers were sold in the more compact Micro-ITLA form factor, which cut the original ITLA package size in half. And in 2019, laser developers (see examples here and here) announced a new Nano-ITLA form factor that reduced the size by almost half again.

Integration also has a major impact on power consumption, since smaller, highly-integrated lasers usually consume less power than bulkier lasers with more discrete components. Making the laser smaller and more integrated means that the light inside the chip will travel a smaller distance and therefore accumulate fewer optical losses.

Reducing the footprint of tunable lasers in the future will need even greater integration of their component parts. For example, every tunable laser needs a wavelength locker component that can stabilize the laser’s output regardless of environmental conditions such as temperature. Integrating the wavelength locker component on the laser chip instead of attaching it externally would help reduce the laser package’s footprint and power consumption.

Configurability and Optimization

Another important aspect of optimizing pluggable module footprint and power consumption is allowing transceiver developers to mix and match their transceiver building blocks.

Let’s discuss an example of such configurability. The traditional ITLA in transceivers contains the temperature control driver and power converter functions. However, the main transceiver board can usually provide these functions too.

A setup in which the main board performs these driver and converter functions would avoid the need for redundant elements in both the main board and tunable laser. Furthermore, it would give the transceiver developer more freedom to choose the power converter and driver blocks that best fit their footprint and power consumption requirements.

Such configurability will be particularly useful in the context of the new generation of 100G coherent pluggables. After, these 100G pluggables must fit tunable lasers, digital signal processors, and optical engines in a QSFP28 form factor that is slightly smaller than the QSFP-DD size used for 400G transceiver.

Looking Towards Electronics Style Packaging

The photonics production chain must be increasingly automated and standardized to save costs and increase accessibility. To achieve this goal, it is helpful to study established practices in the fields of electronics packaging, assembly, and testing.

By using BGA-style packaging or flip-chip bonding techniques that are common now in electronics packaging or passive optical fiber alignment, photonics packaging can also become more affordable and accessible. You can read more about these methods in our article about leveraging electronic ecosystems in photonics.

These kinds of packaging methods not only improve the scalability (and therefore cost) of laser production, but they can also further reduce the size of the laser.

Takeaways

Tunable lasers for coherent pluggable transceivers face the complex problem of maintaining a good enough performance while moving to smaller footprints, lower cost, and lower power consumption. Within a decade, the industry moved from the original integrable tunable laser assembly (ITLA) module to micro-ITLAs and then nano-ITLAs. Each generation had roughly half the footprint of the previous one.

However, the need for 100G coherent pluggables for the network edge imposes even tighter footprint and power consumption constraints on tunable lasers. Increased integration, more configurability of the laser and transceiver building blocks, and the leveraging of electronic will help tunable lasers get smaller and more power-efficient to enable these new application cases in edge and access networks.