Transforming where Light meets Digital for Increased Connectivity

With the explosive growth in AI and cloud, the demand for bandwidth and faster data transfer capabilities is more necessary than ever. EFFECT Photonics uses its digital-to-light technologies to interconnect our ever-changing world by providing solutions that are sustainable, cost-efficient and scalable.

As a highly vertically integrated, independent and global optical systems company, we aim to disrupt, challenge and simplify what possible in datacom and telecom networks so that people can be connected to whatever, whomever, whenever and however they choose.

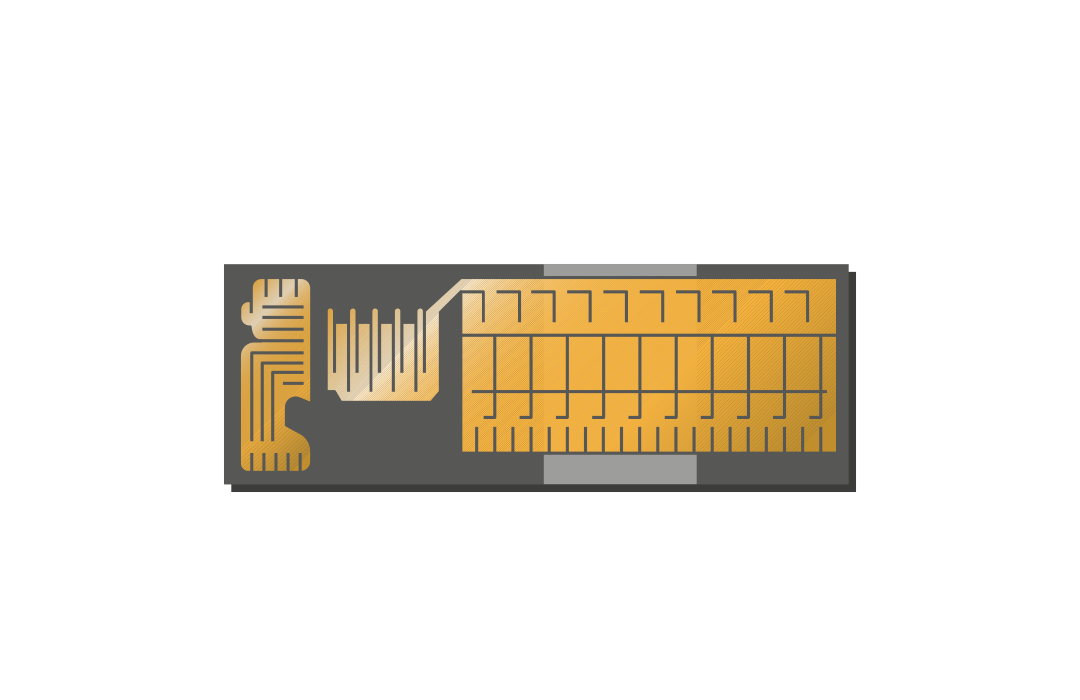

Make Cutting Edge Technology Broadly Available

Bringing cutting-edge technology from the core to the edge through low power DSPs and broad adoption of tunable lasers.

Accelerate Network Transformation & Sustainability

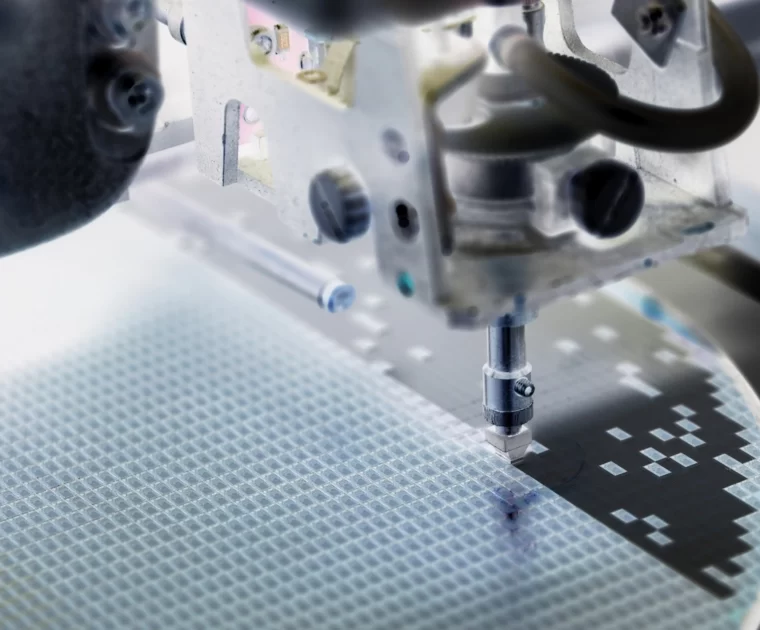

Facilitate optical interconnectivity and energy transition with co-design of optics & electronics.

Enable The Art Of The Possible

Enabling industrywide innovation and offering options by making sub-components available to the ecosystem that are aligned to open standards and interoperability.