Insights

AI and the New Drivers of Data Traffic

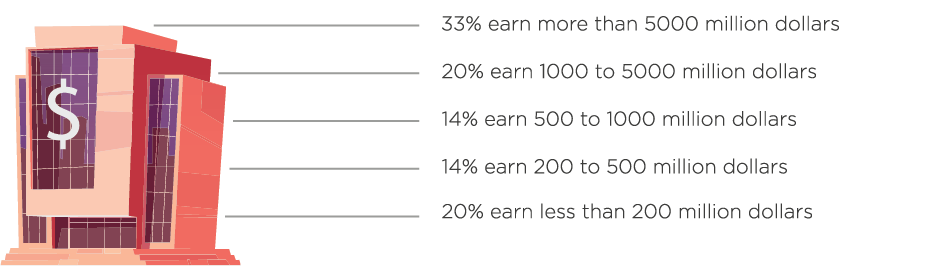

In this world, nothing can be said to be certain except death, taxes, and the…

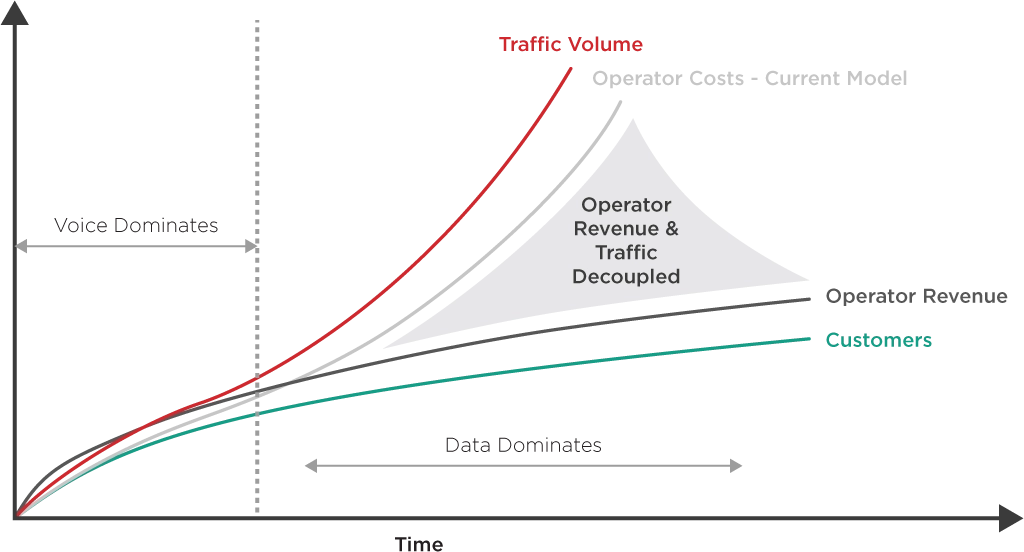

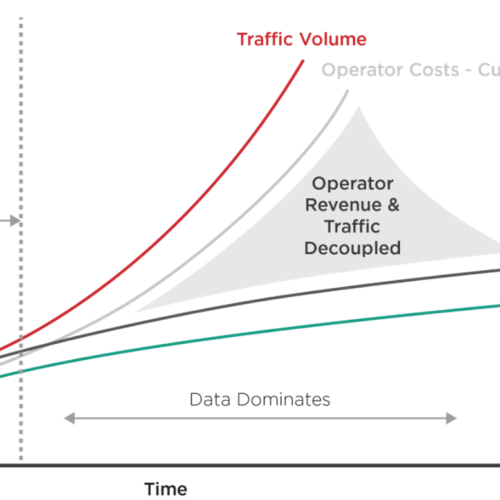

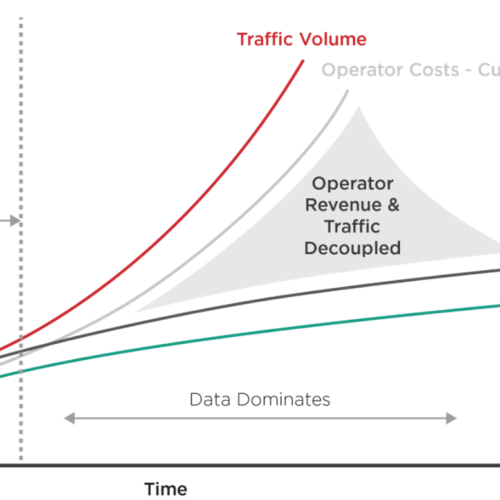

In this world, nothing can be said to be certain except death, taxes, and the growth of data traffic in communication networks. However, the causes of that growth vary over time depending on emerging technologies and shifting consumer behaviors.

The relationship between network capacity and data traffic closely mirrors the concept of induced demand in highway traffic management. Induced demand in the context of roadways refers to the phenomenon where increasing the number of lanes or expanding the road infrastructure to reduce congestion and accommodate more vehicles often leads to even higher traffic volumes. This is because the improved road capacity makes driving more appealing, thus encouraging more people to use their vehicles or to use them more often.

Similarly, as network capacity is increased—be it through the expansion of bandwidth or the introduction of more efficient data transmission—the network becomes capable of supporting higher loads and faster services. This improvement in network performance can encourage more data-intensive applications and services to be developed and used, such as high-definition video streaming, real-time gaming, and comprehensive Internet-of-things (IoT) solutions. As a result, the demand for data grows further, often at a pace that quickly meets or even exceeds the newly added capacity.

This article will tackle some recent key trends of the last couple of years that are driving the latest surge in data traffic.

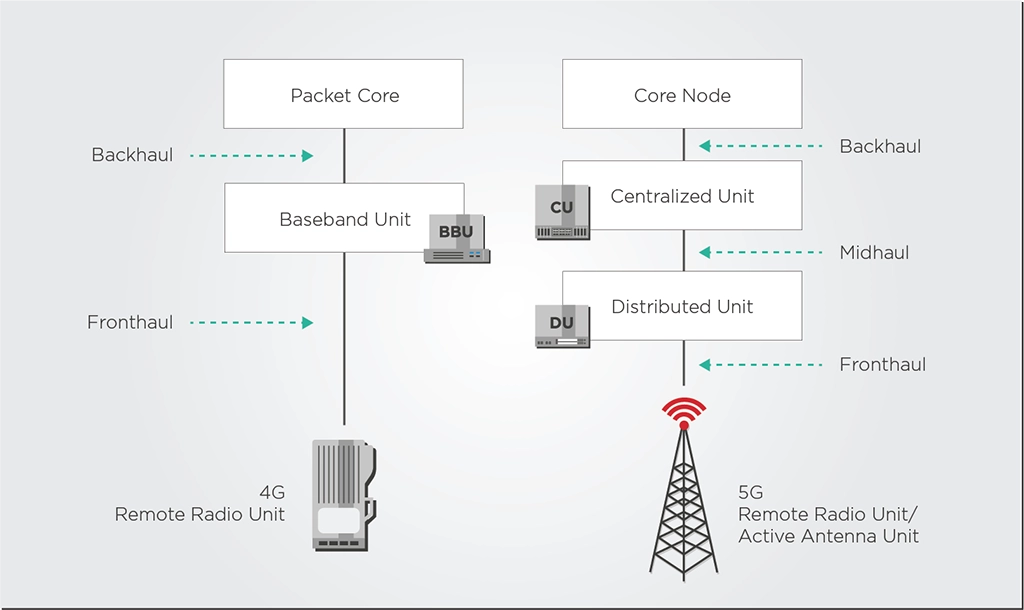

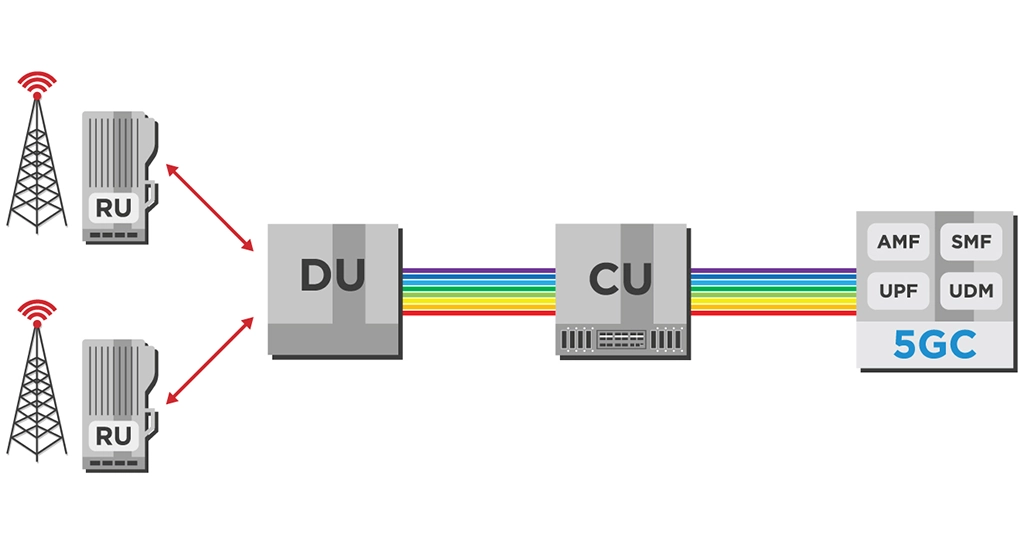

5G and the Internet of Things

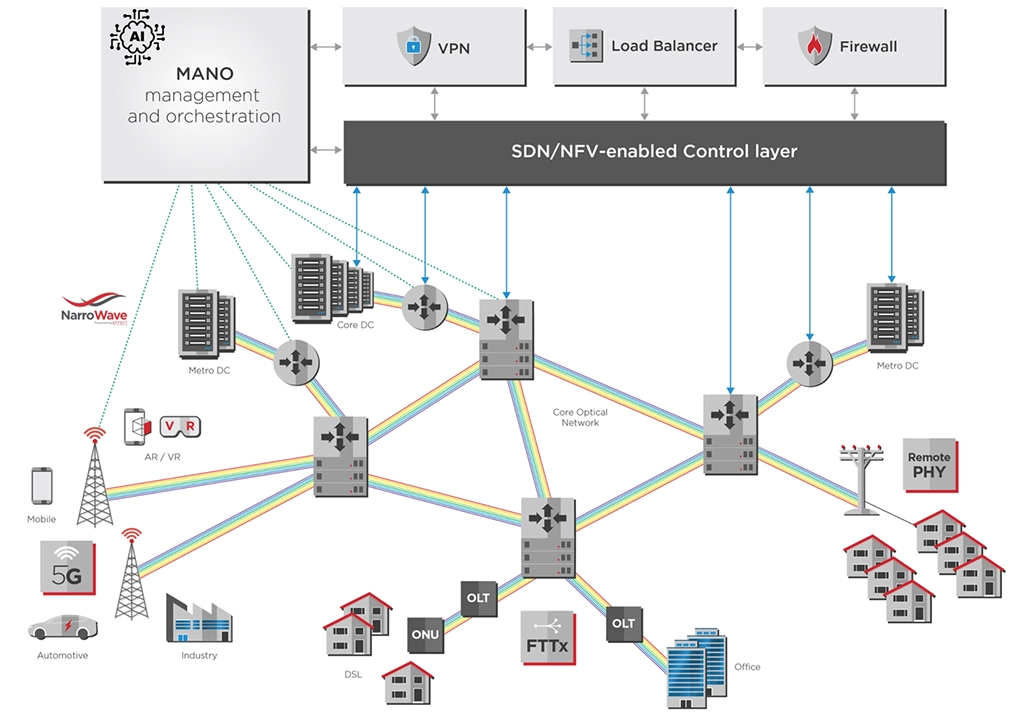

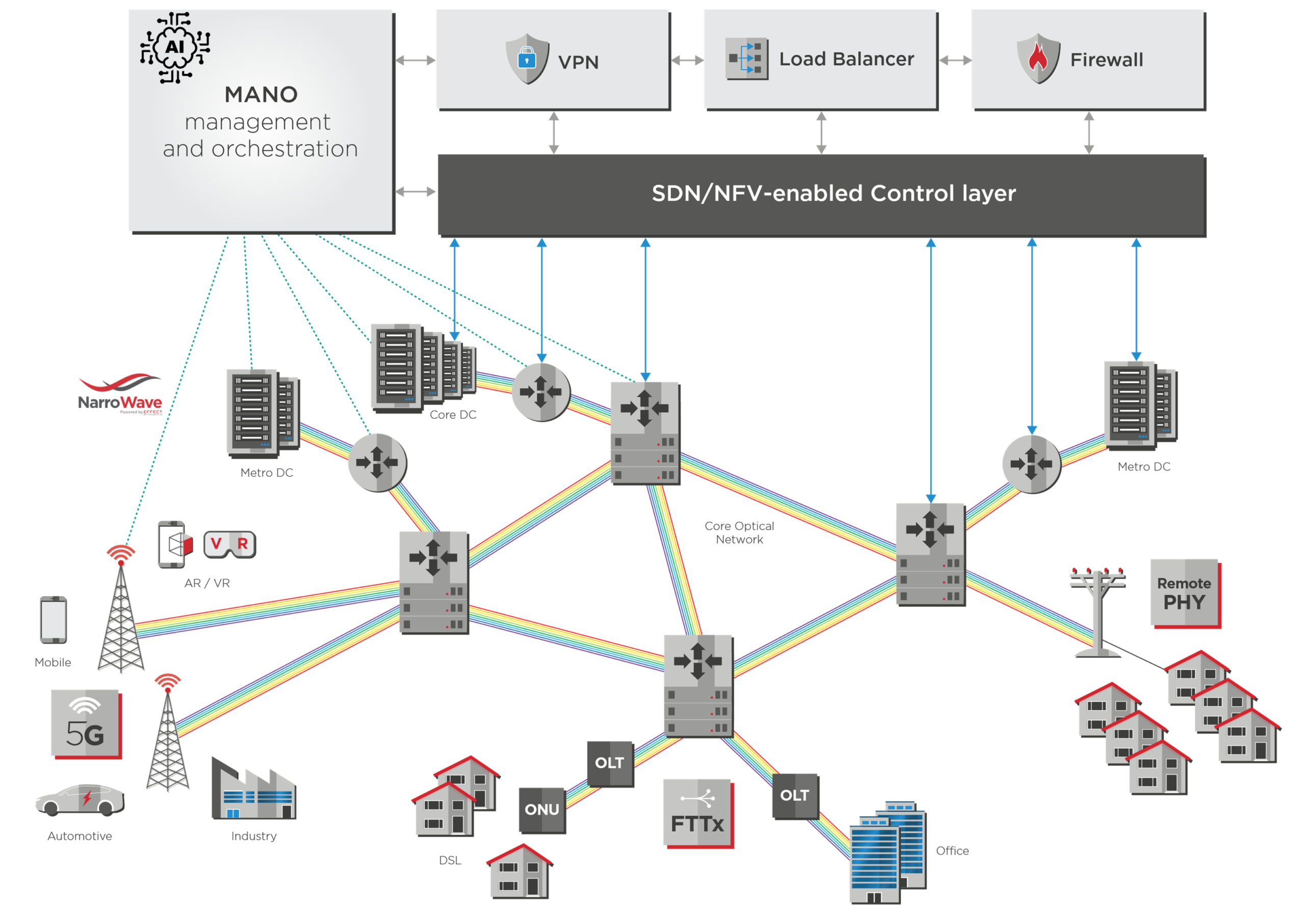

The Internet of Things (IoT) is a series of technologies interconnecting physical devices, allowing them to communicate, collect, and exchange data without human intervention. This connectivity enhances operational efficiency, improves safety, and reduces human labor in various environments—from industrial settings with automated production lines to everyday consumer use, such as smart home devices that enhance user convenience and energy efficiency.

By converting ordinary objects into smart, connected components, IoT enables real-time data collection and analysis. This leads to more informed decision-making and predictive maintenance, which can significantly cut costs and increase productivity across multiple sectors.

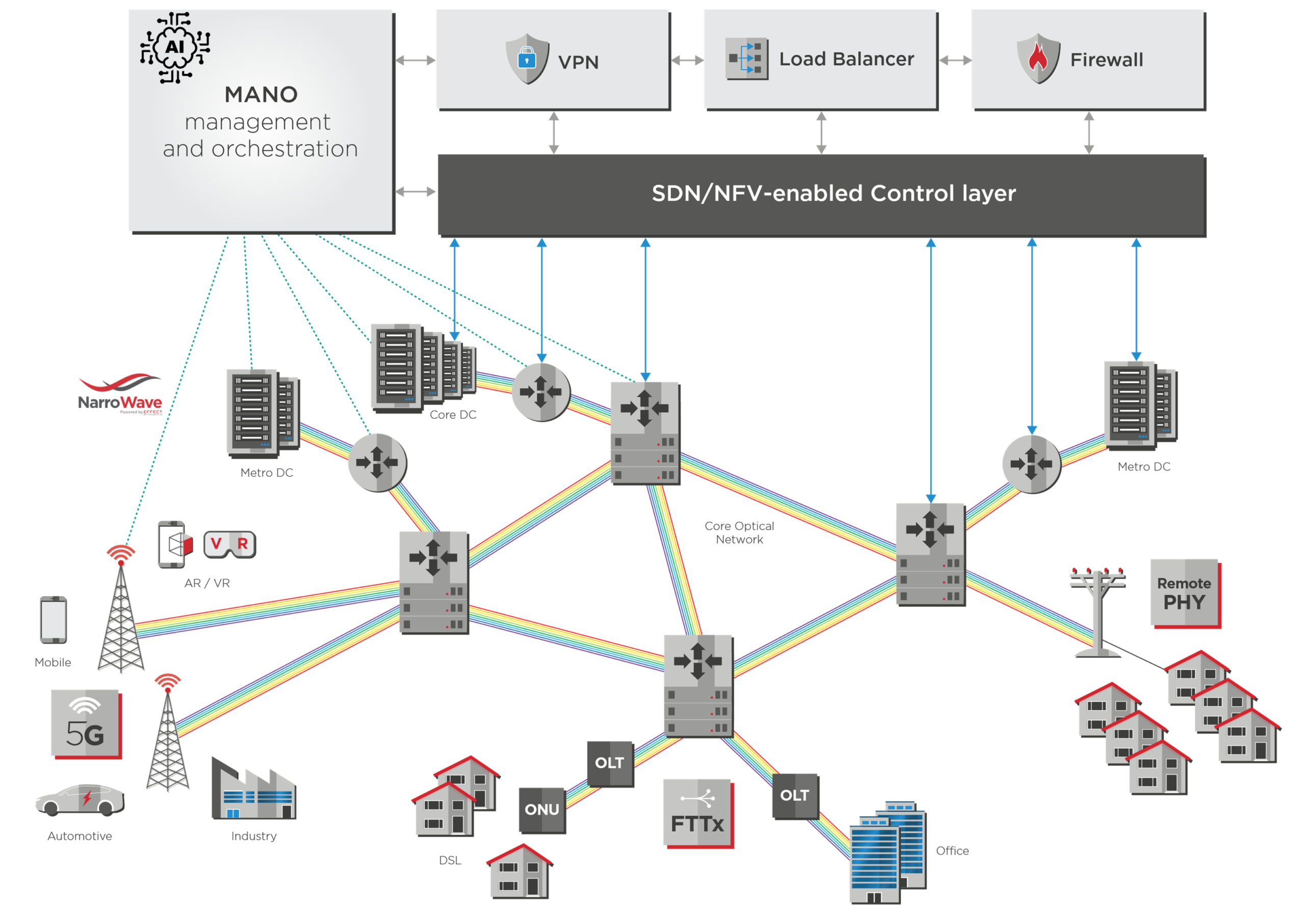

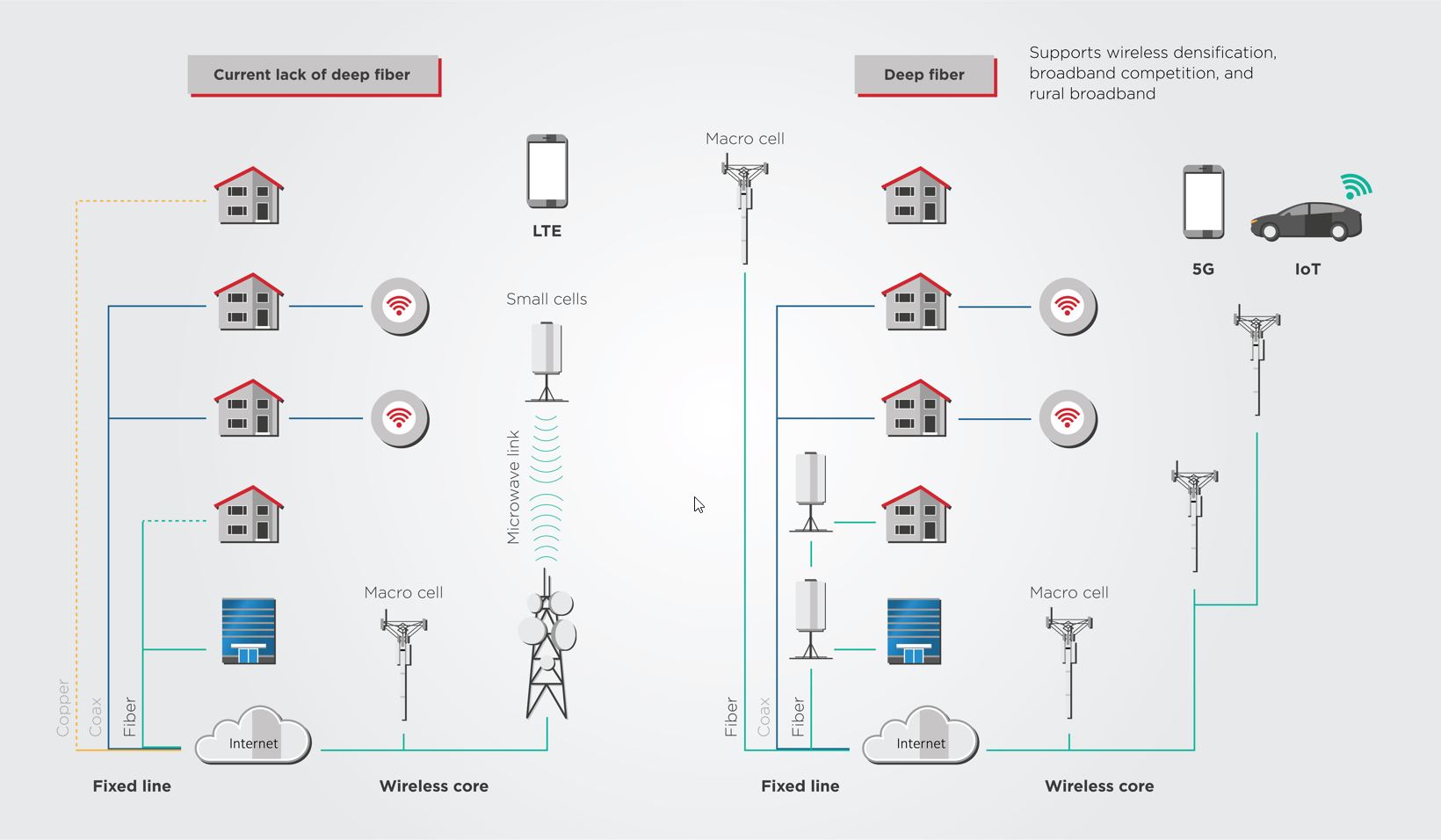

The advent of 5G technology, with its promise of ultra-fast speeds and low latency, has enabled many IoT applications, turning mundane devices into smart, interconnected components of broader digital ecosystems. However, this means more devices contribute to the already vast data streams flowing through global networks.

Cloud Computing and the Edge

Cloud computing offers scalable and flexible IT resources over the Internet, allowing businesses to avoid the upfront cost and complexity of owning and maintaining their own IT infrastructure. By leveraging cloud services, organizations can access a wide array of computing resources on demand, such as servers, storage, databases, and software applications.

Meanwhile, applications such as IoT, AR/VR, and content delivery networks have driven the growth of edge computing. Edge computing complements cloud computing by processing data near the source rather than relying on a central data center. This is important for applications requiring real-time processing and low latency, such as autonomous vehicles, industrial automation, and smart city technologies. By minimizing the distance data must travel, edge computing reduces latency, increases data processing speed, and enhances sensitive data’s reliability and privacy.

As shown in Table 1, a data center on a town or suburb aggregation point could halve the latency compared to a centralized hyperscale data center. Enterprises with their own data center on-premises can reduce latencies by 12 to 30 times compared to hyperscale data centers.

Types of Edge Data Centres

| Types of Edge | Data center | Location | Number of DCs per 10M people | Average Latency | Size | |

|---|---|---|---|---|---|---|

| On-premises edge | Enterprise site | Businesses | NA | 2-5 ms | 1 rack max | |

| Network (Mobile) | Tower edge | Tower | Nationwide | 3000 | 10 ms | 2 racks max |

| Outer edge | Aggregation points | Town | 150 | 30 ms | 2-6 racks | |

| Inner edge | Core | Major city | 10 | 40 ms | 10+ racks | |

| Regional edge | Regional edge | Regional | Major city | 100 | 50 ms | 100+ racks |

| Not edge | Not edge | Hyperscale | State/national | 1 | 60+ ms | 5000+ racks |

As more people and organizations adopt cloud-based services and as these services become more data-intensive (e.g., high-definition video streaming, large-scale machine learning models), the volume of data traversing the internet continues to grow. While edge computing processes much of the data locally to reduce latency, it increases data traffic in the access networks connected to edge devices.

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are deeply transforming many industries, enabling increased automation of man tasks. AI employs sophisticated algorithms to interpret data, automate decisions, and act upon those decisions. Machine learning, a branch of AI, focuses on algorithms that allow computers to learn from data to make predictions or decisions without explicit programming. This capability is essential for many applications, from spam detection in emails to more complex problems such as diagnosing diseases or managing traffic flows efficiently.

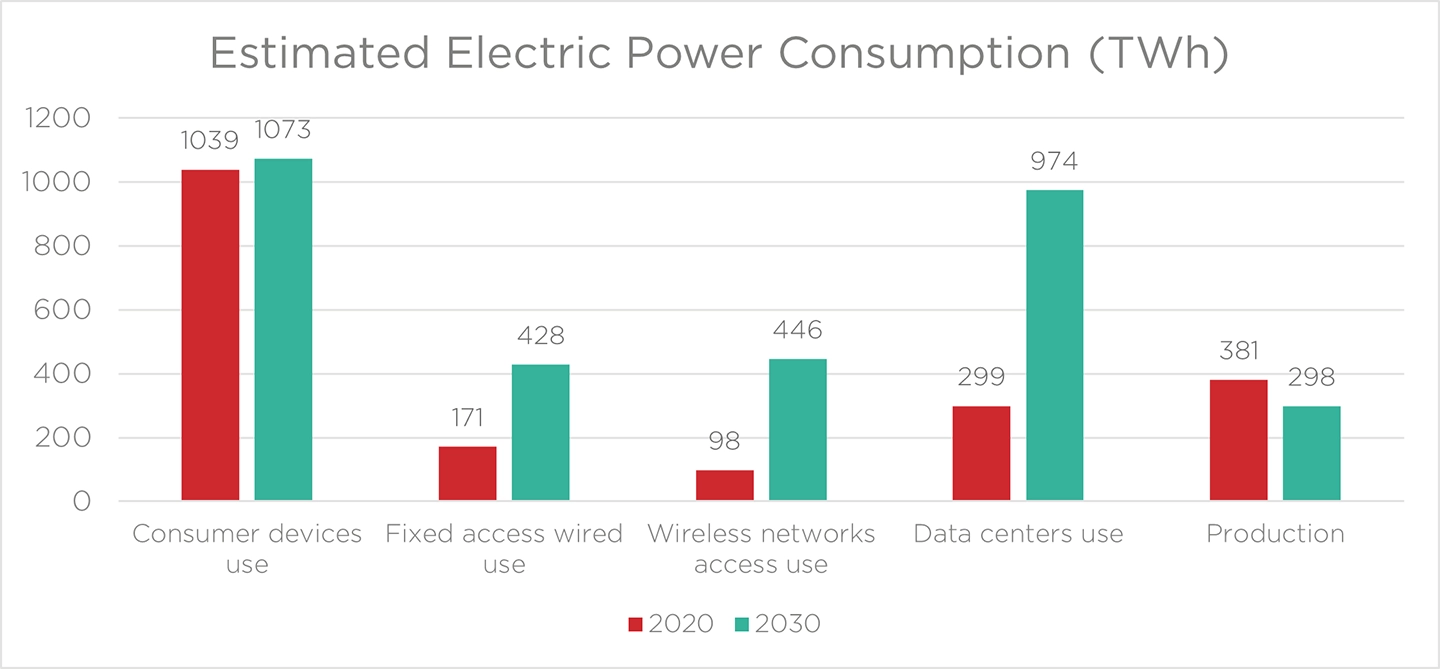

AI and ML significantly increase data traffic due to several factors:

- Data Collection: Training and operating AI/ML models require extensive data collection from varied sources. This data must be transmitted to where it can be processed, contributing to substantial network traffic.

- Connectivity Increase: Integrating AI in devices and services, such as IoT or smart devices, leads to more internet-connected devices and higher data volumes being transmitted to central servers for analysis.

- Complex Computations: AI and ML computations usually occur in cloud environments, necessitating high-capacity links for processing and subsequent results downloads.

The increasing complexity of AI processing will impact not just the interconnections between data centers but also the architectures inside the data center. AI nodes inside data center racks are normally connected via electrical or RF signals, while the racks are connected via optical fiber interconnects. However, as AI systems do more parallelized processing, data center racks run into electrical memory and power consumption constraints. These electrical interconnects between AI nodes are increasingly becoming a bottleneck in the ability of data center architectures to scale and handle the demands of AI models sustainably.

Takeaways

Emerging technologies such as 5G, IoT, cloud computing, and AI on data traffic are reshaping how data is generated, processed, and used across networks. Cloud computing continues democratizing access to technological resources, enabling businesses and individuals to leverage sophisticated tools without significant upfront investments. The Internet of Things (IoT) turns everyday objects into devices connected to 5G networks and the edge cloud. AI and machine learning represent perhaps the most significant drivers of increased data traffic, as they rely on massive data sets to train and operate.

These technologies will have a major impact on our society but will also need further innovations in network architecture to handle increased loads with minimal latency. Integrating AI across various devices and services not only multiplies the number of data-generating interactions but also complicates the data processing infrastructure, pushing the limits of current technologies and requiring new solutions to sustain growth. These are the challenges that drive the work of telecom and datacom companies all over the world.

Tags: 5G data surge, AI and 5G technology, AI and IoT integration, AI data traffic, AI impact on networks, AI in communication networks, AI machine learning traffic, AI-driven data increase, cloud computing data, data traffic growth, data-intensive applications, Edge computing, EFFECT Photonics, high-definition video streaming, induced demand in data networks, Internet of Things (IoT) traffic, network architecture innovations, network capacity and AI, new data traffic drivers, real-time data processing, smart devices and data traffic

Towards the 800ZR Future

The advances in electronic and photonic integration allowed coherent technology for metro DCIs to be…

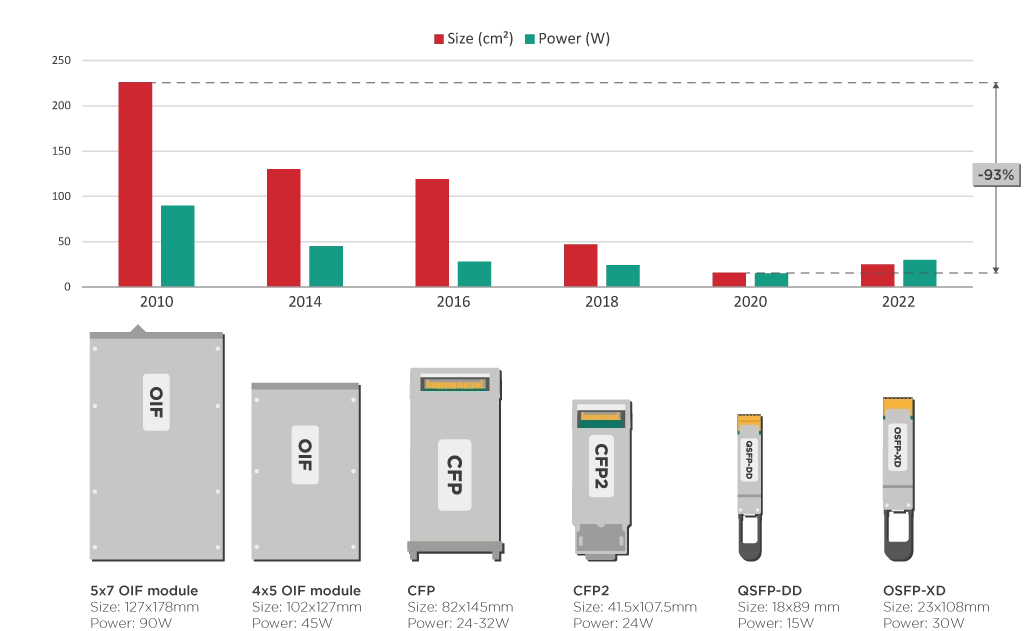

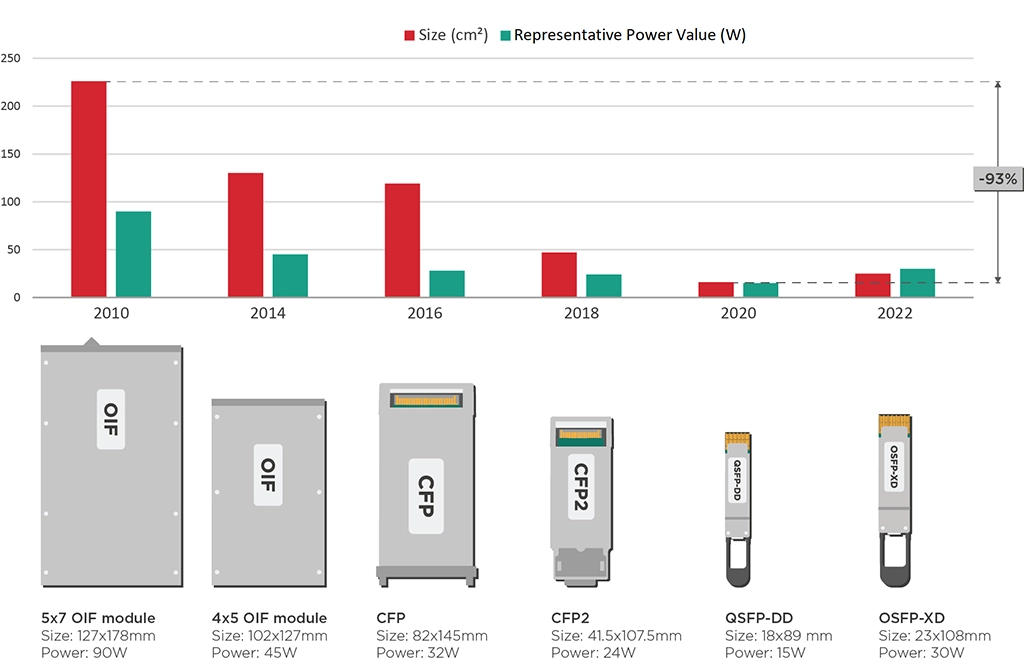

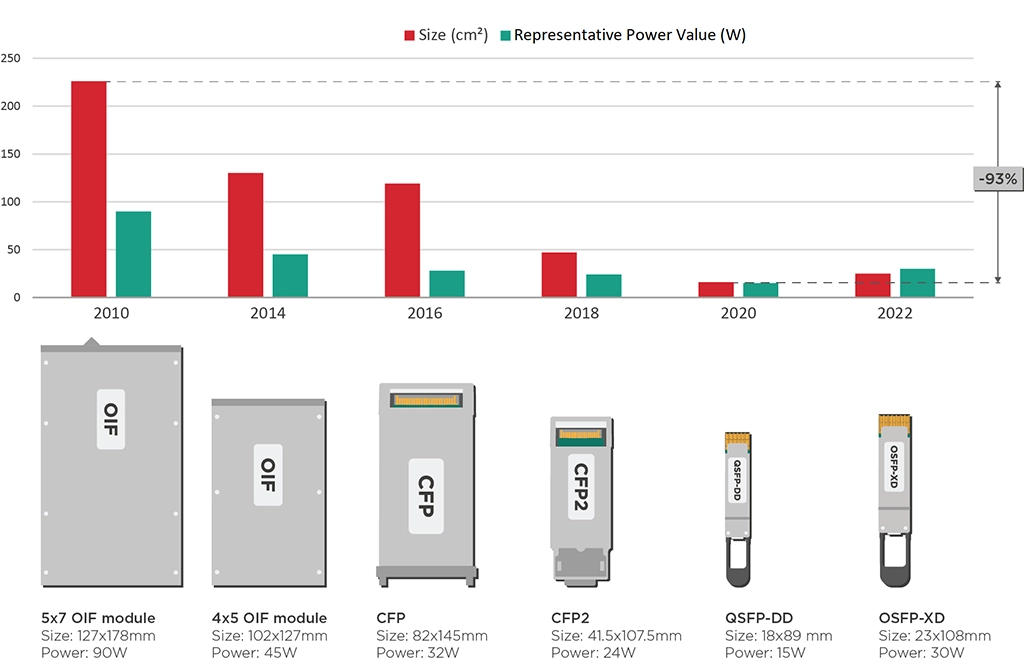

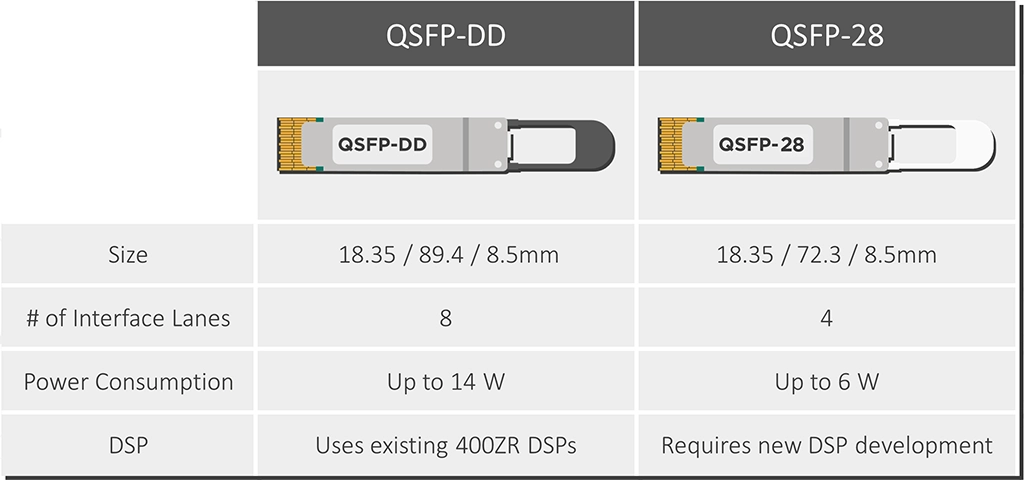

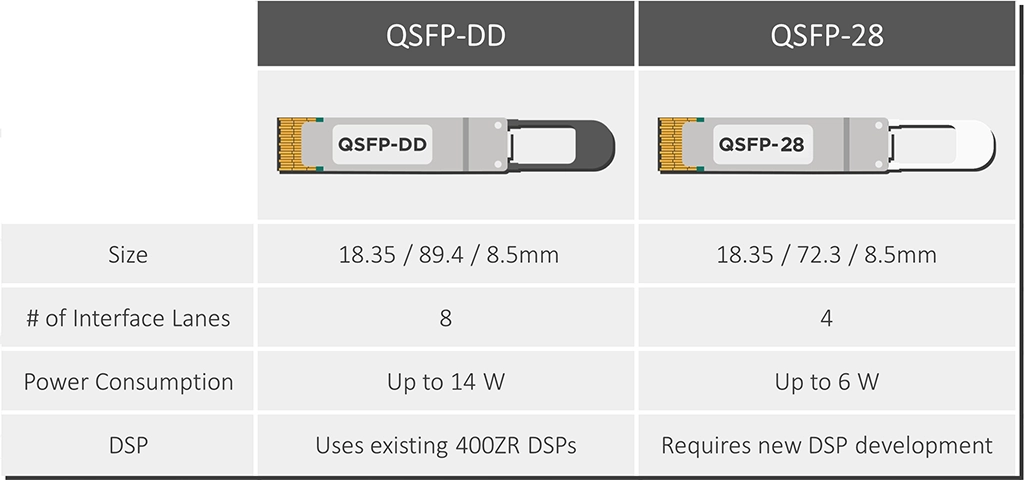

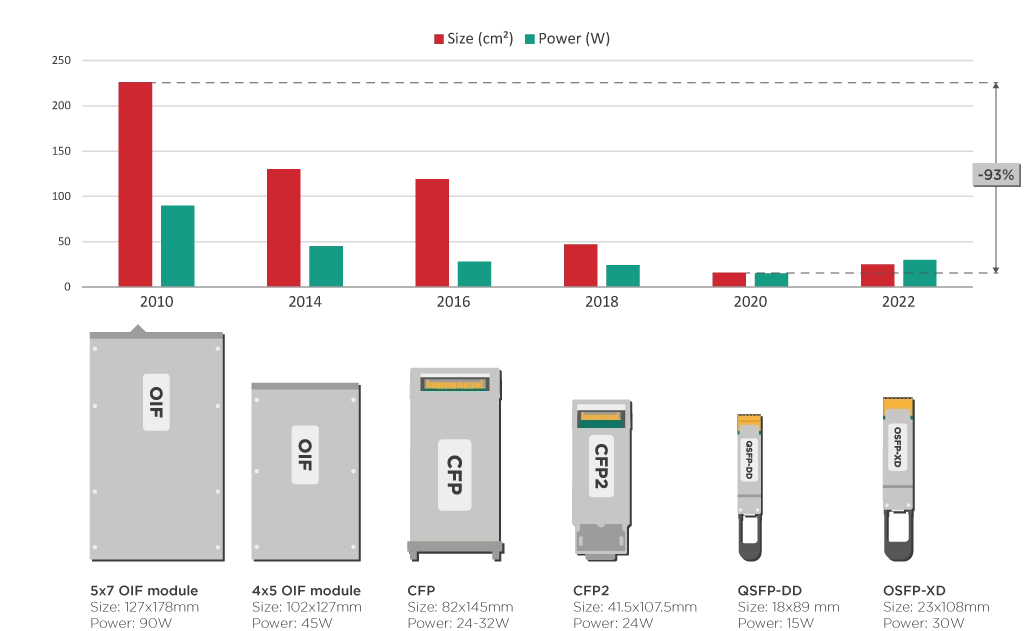

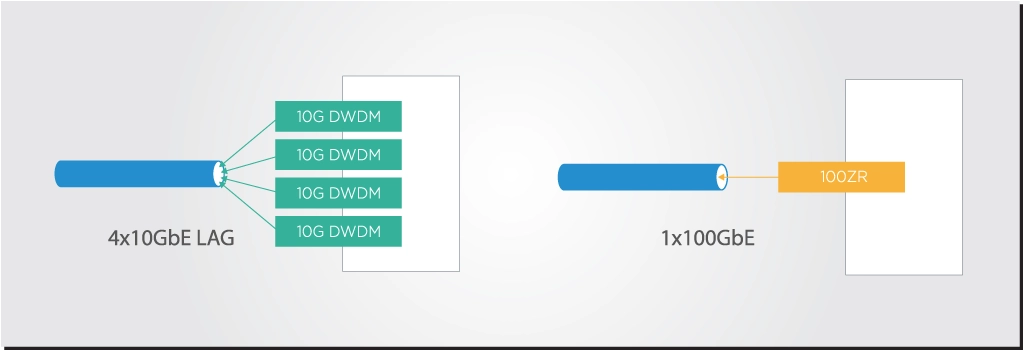

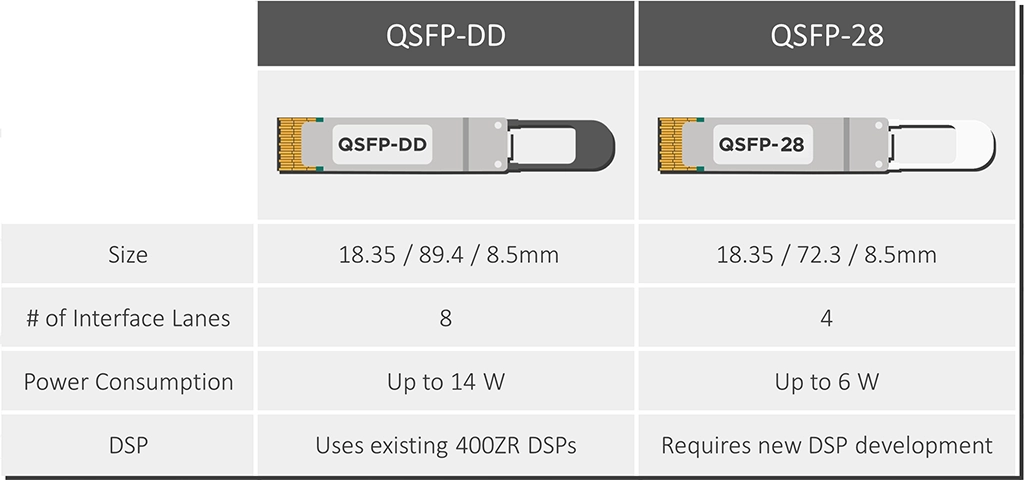

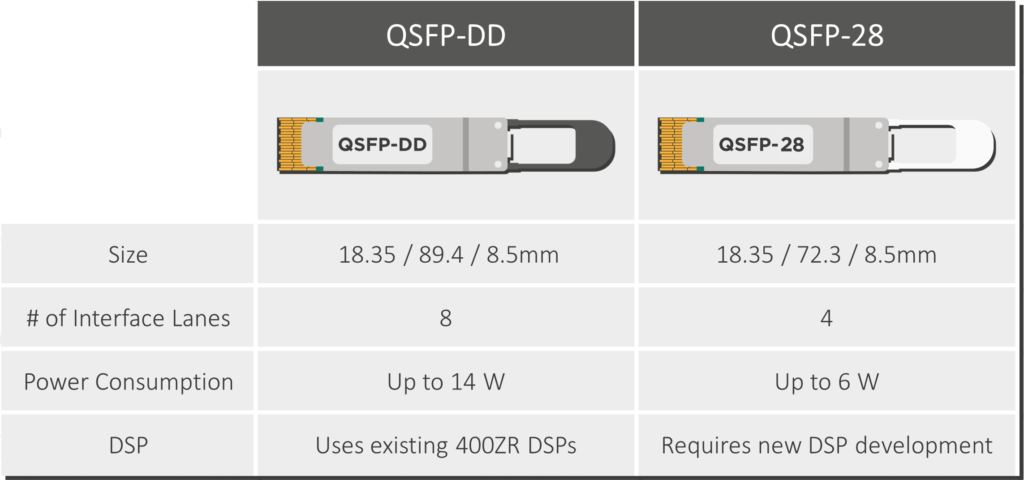

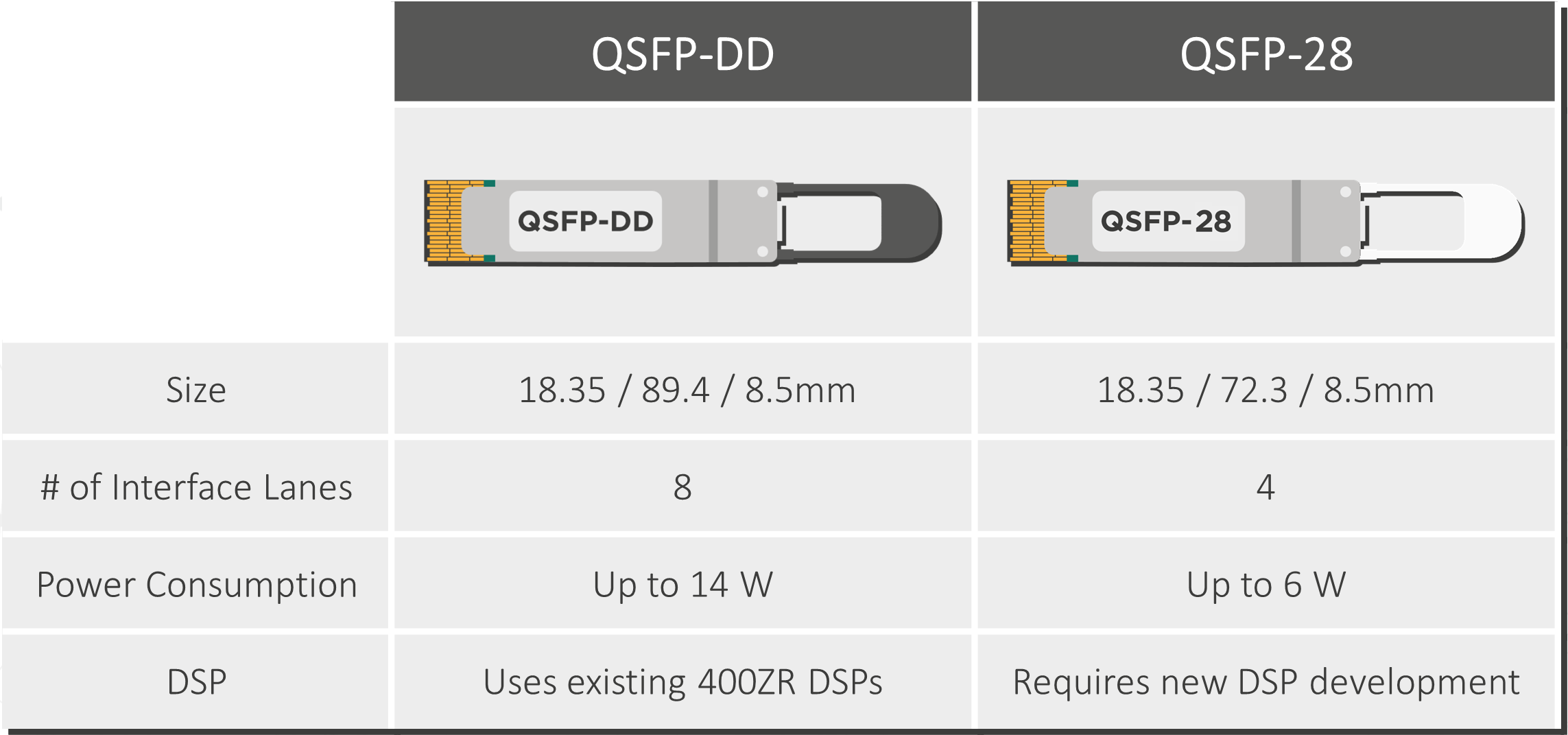

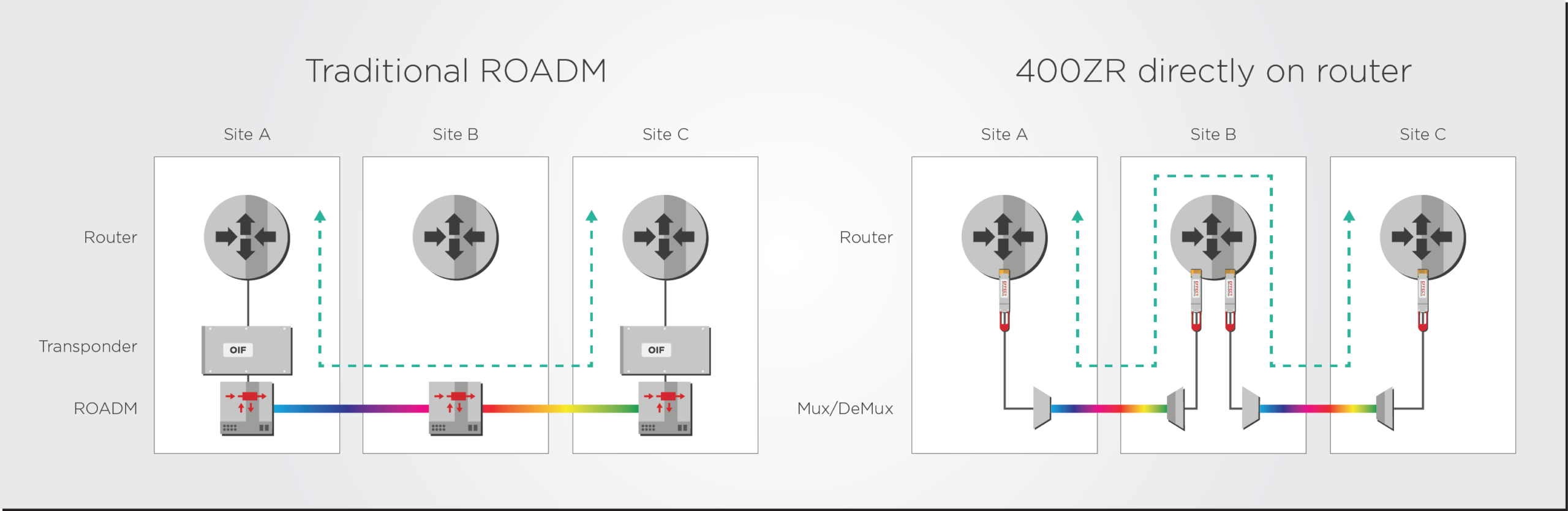

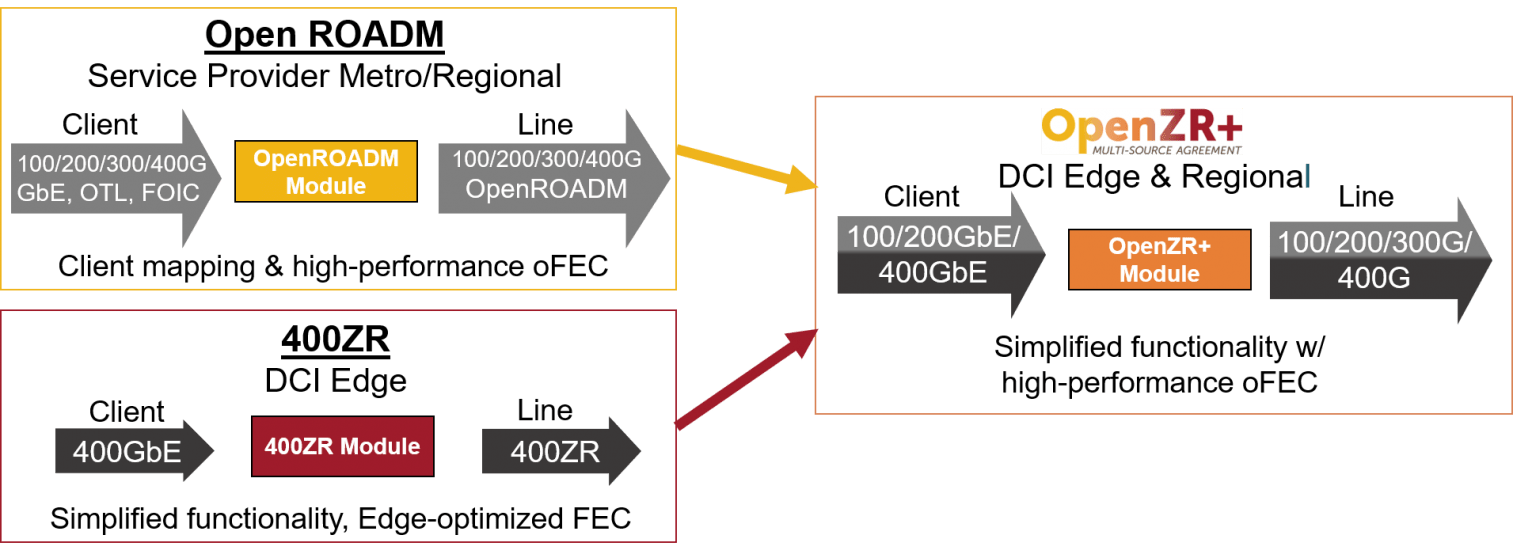

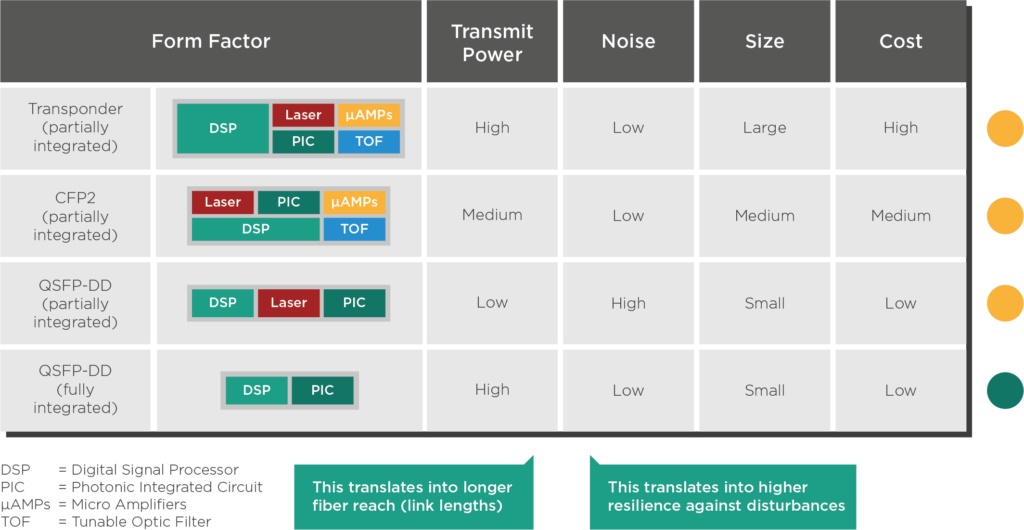

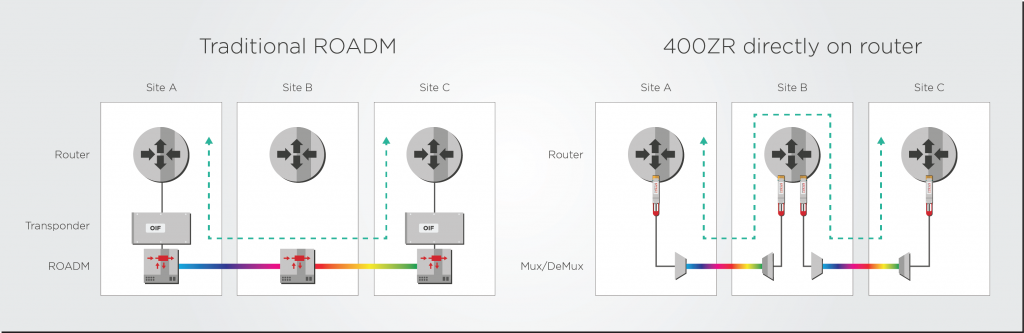

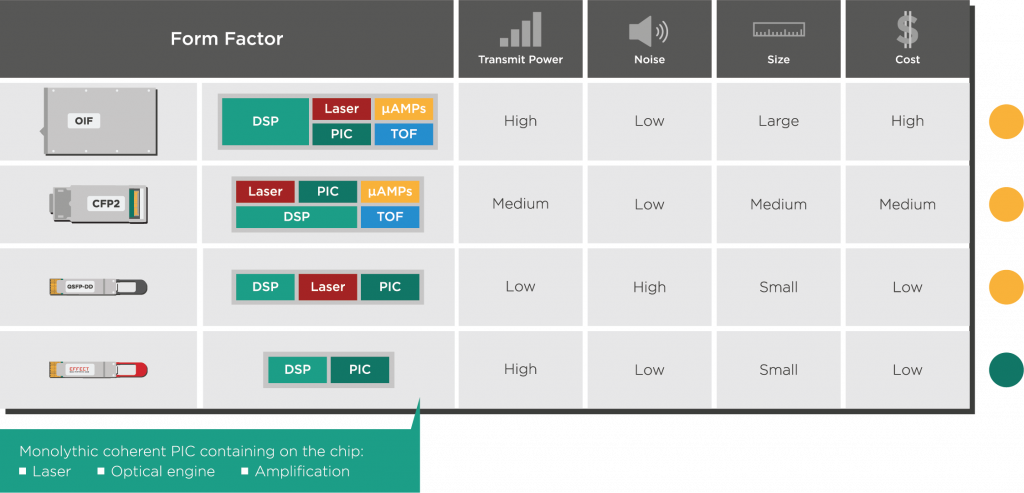

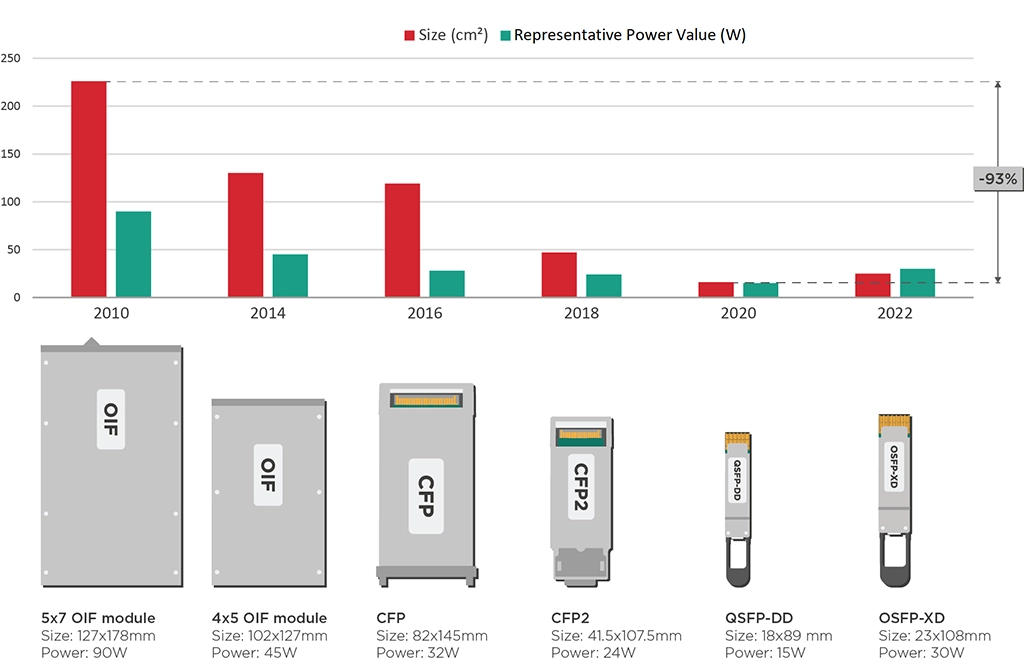

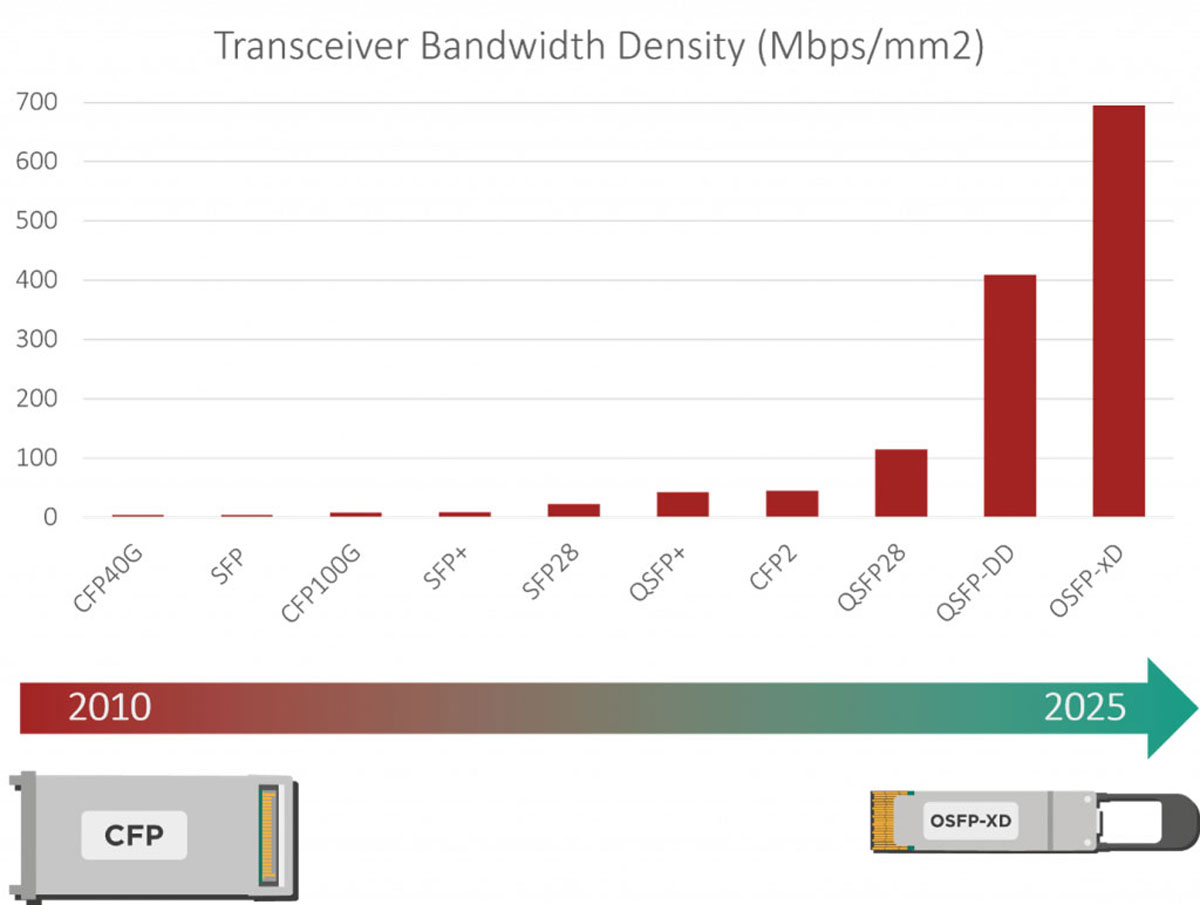

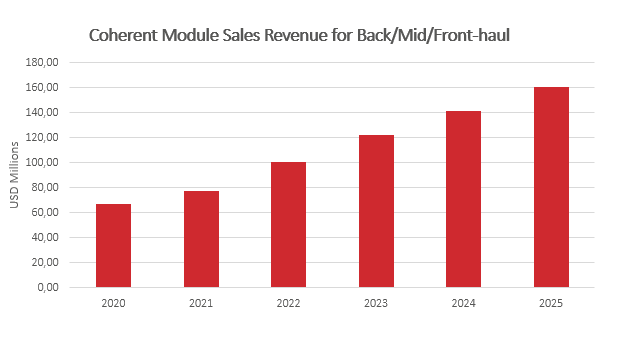

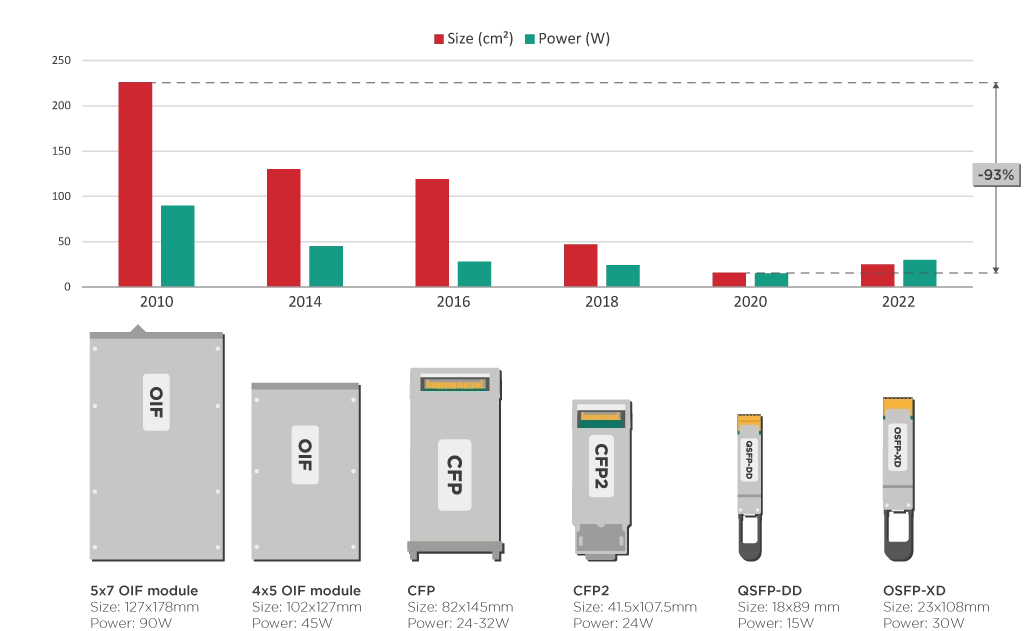

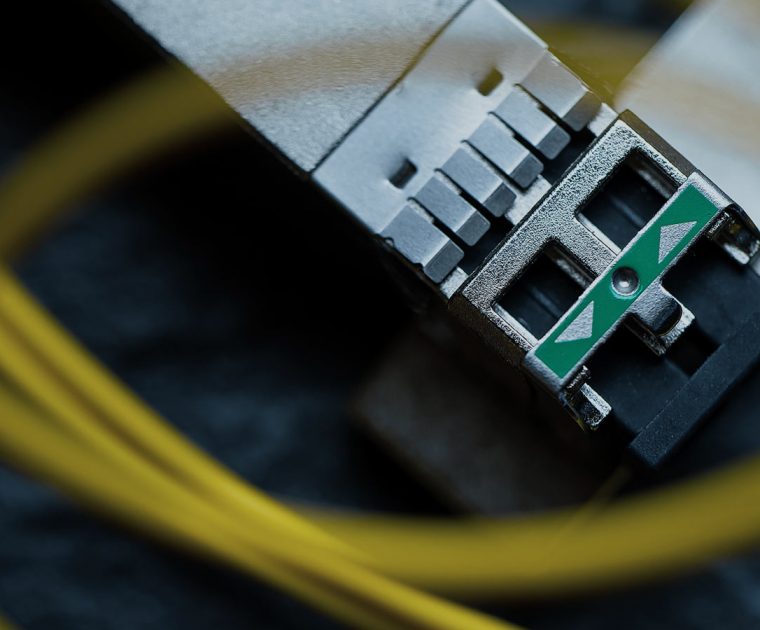

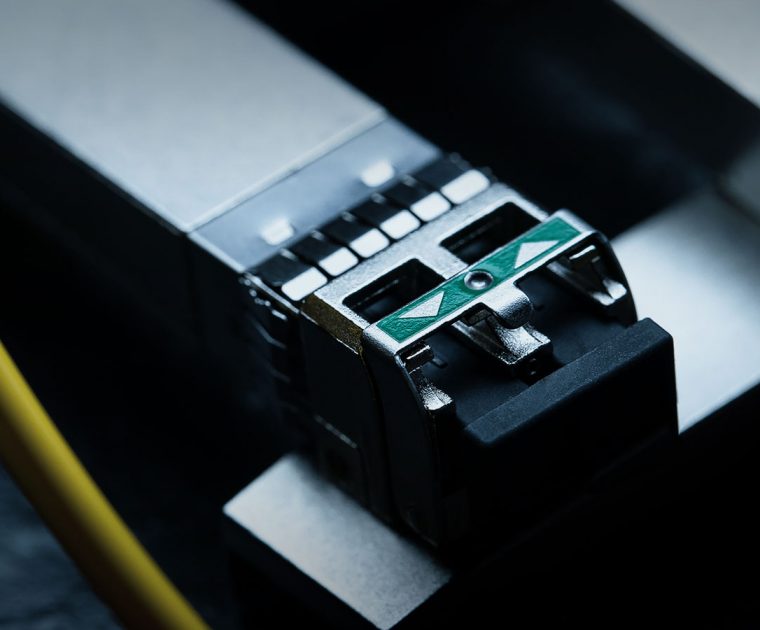

The advances in electronic and photonic integration allowed coherent technology for metro DCIs to be miniaturized into QSFP-DD and OSFP form factors. This progress allowed the Optical Internetworking Forum (OIF) to create the 400ZR and ZR+ standards for 400G DWDM pluggable modules.

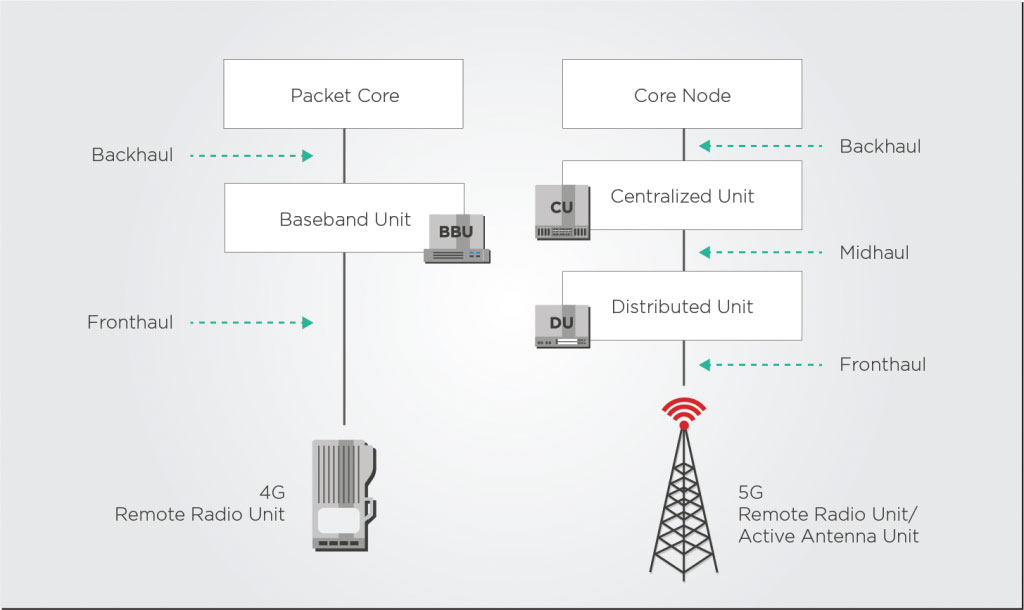

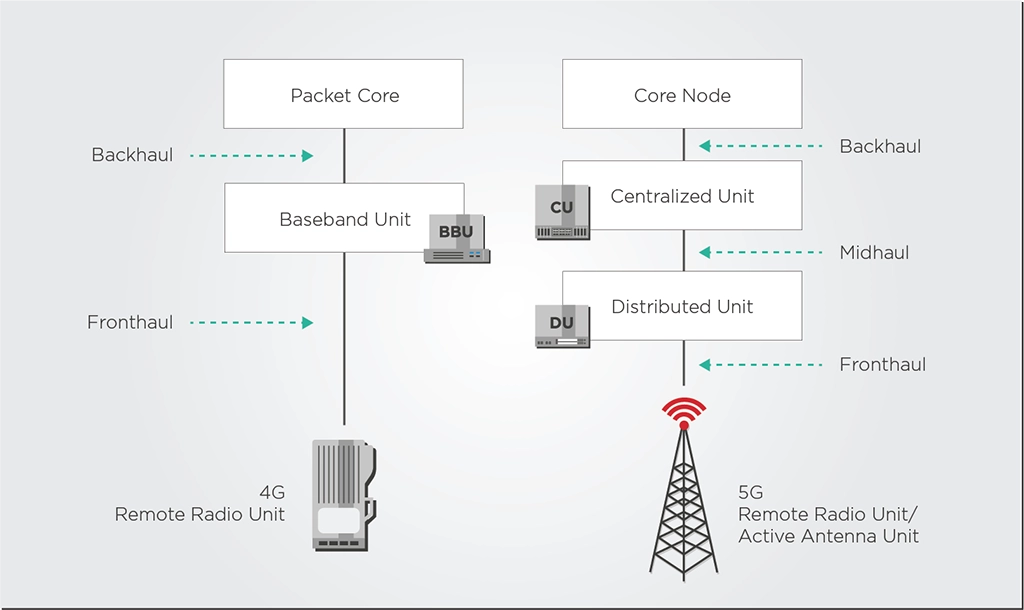

Following the success of 400ZR standardization, the industry quickly recognized the need for even higher-capacity solutions. In December 2020, the Optical Internetworking Forum (OIF) announced the initiation of the 800G Coherent project. This project aimed to define interoperable 800 Gbps coherent line specifications for various applications, including amplified DWDM links up to 120 km and unamplified fixed wavelength links of 2-10 km.

After the success of 400ZR standardization, the data center industry and the OIF are starting to promote an 800ZR standard to enable the next generation of interconnects. In OFC 2024, we started seeing some demos from several vendors and the OIF on this new standards initiative.

Coherent or Direct Detect for Data Centers

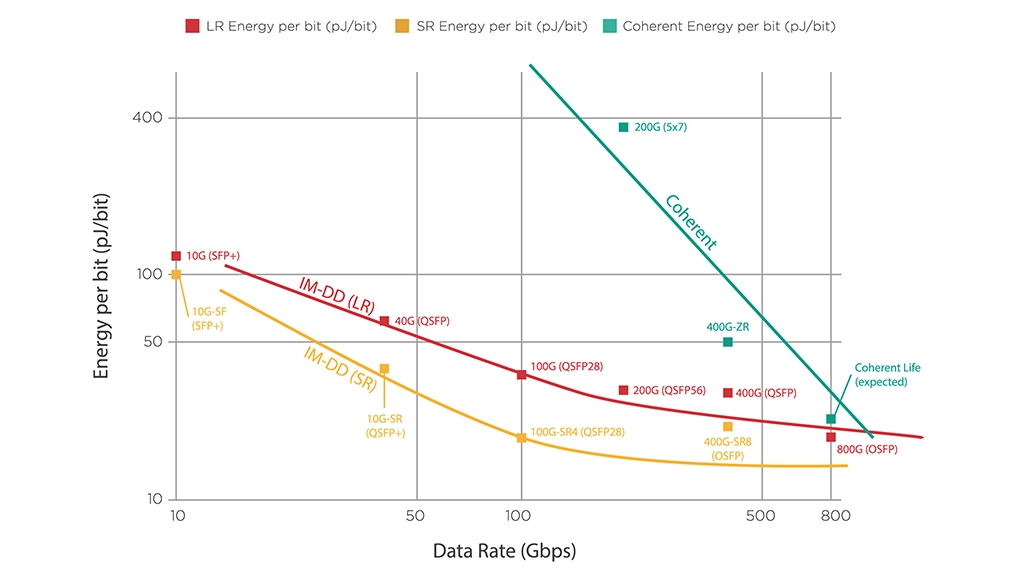

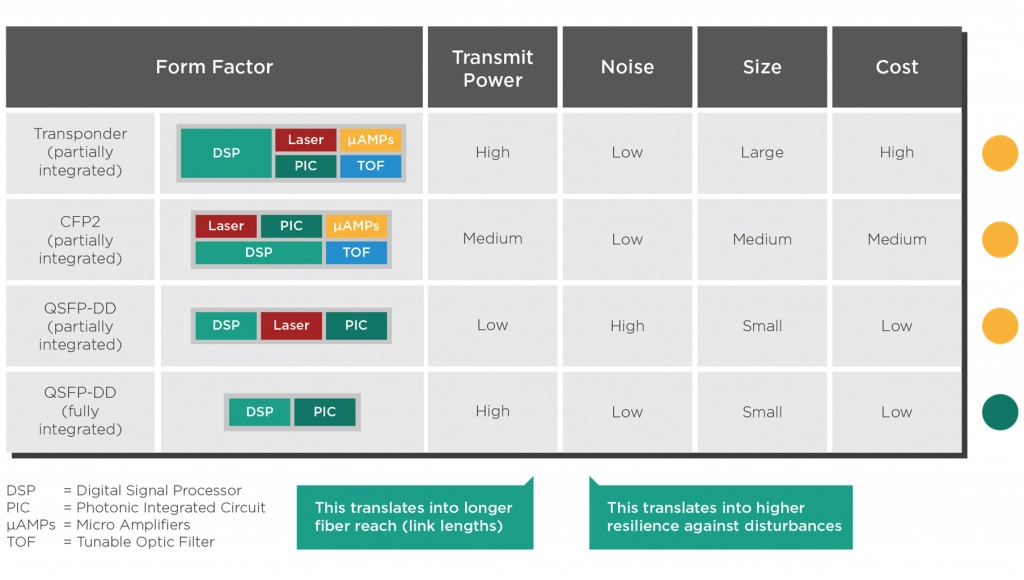

While coherent technology has become the dominant one for interconnecting data centers over long distances (80 km upwards), the campus sector and the inside of the data center continue to be dominated by direct detection technologies such as PAM-4.

However, as data rates rise into 800Gbps and beyond, the power consumption of coherent technology is expected to come much closer to that of direct detect PAM-4 solutions, as shown in the figure below. This can make coherent technology competitive for campus interconnects while direct detect technology remains dominant inside the data center.

A major reason for this decreased gap is that direct detect technology often requires additional amplifiers and compensators at these data rates, while coherent pluggables do not. This also makes coherent technology simpler to deploy and maintain. Furthermore, as the volume of coherent transceivers produced increases, their prices can also go down.

While the 800ZR standard is focused on longer-distance metro interconnects, efforts have also been made to develop a coherent 800G short-reach(SR) standard. Even if these efforts are unsuccessful in this generation of transceivers, they can lay the groundwork for using coherent technology in short-reach once terabit links become the new standard.

The Challenge of Power

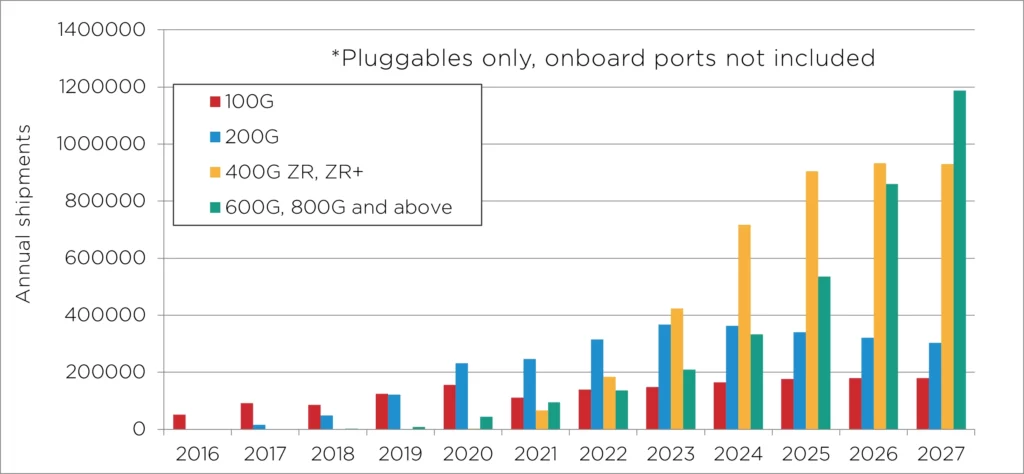

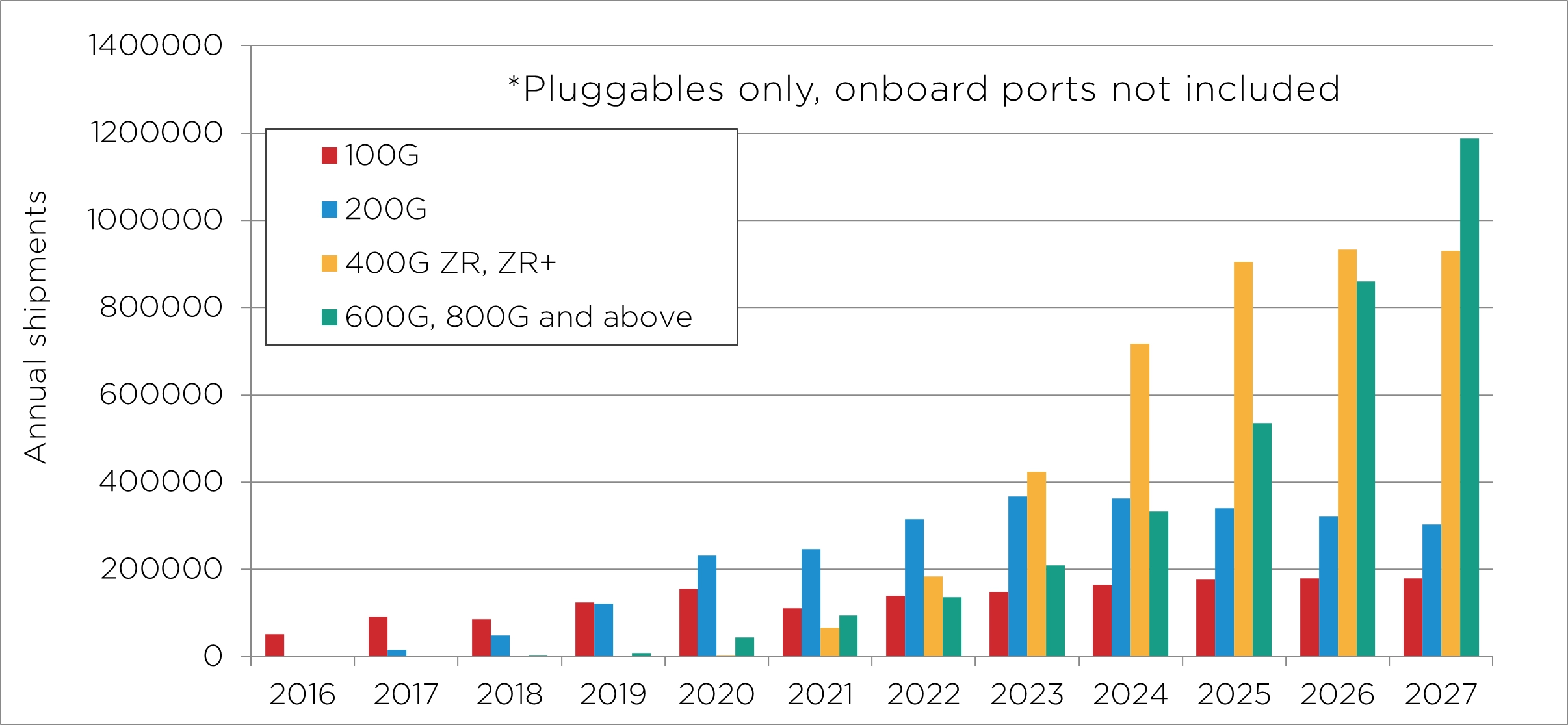

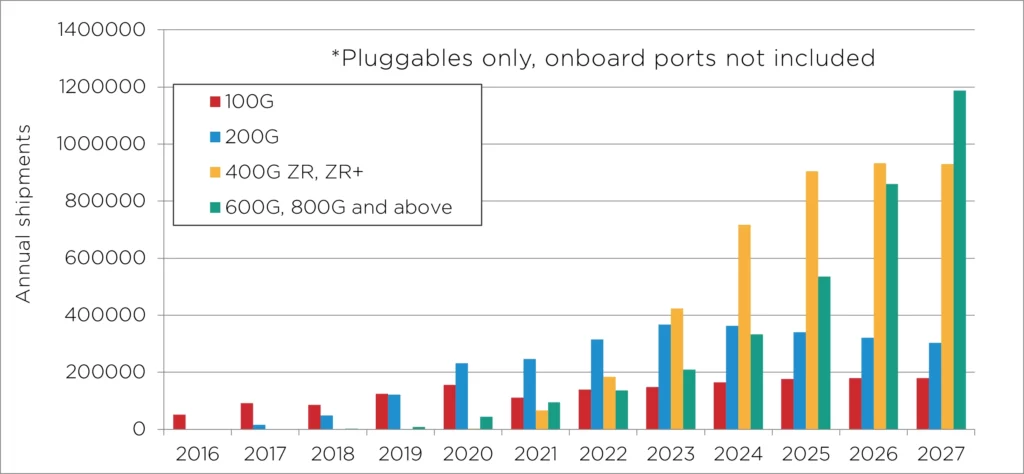

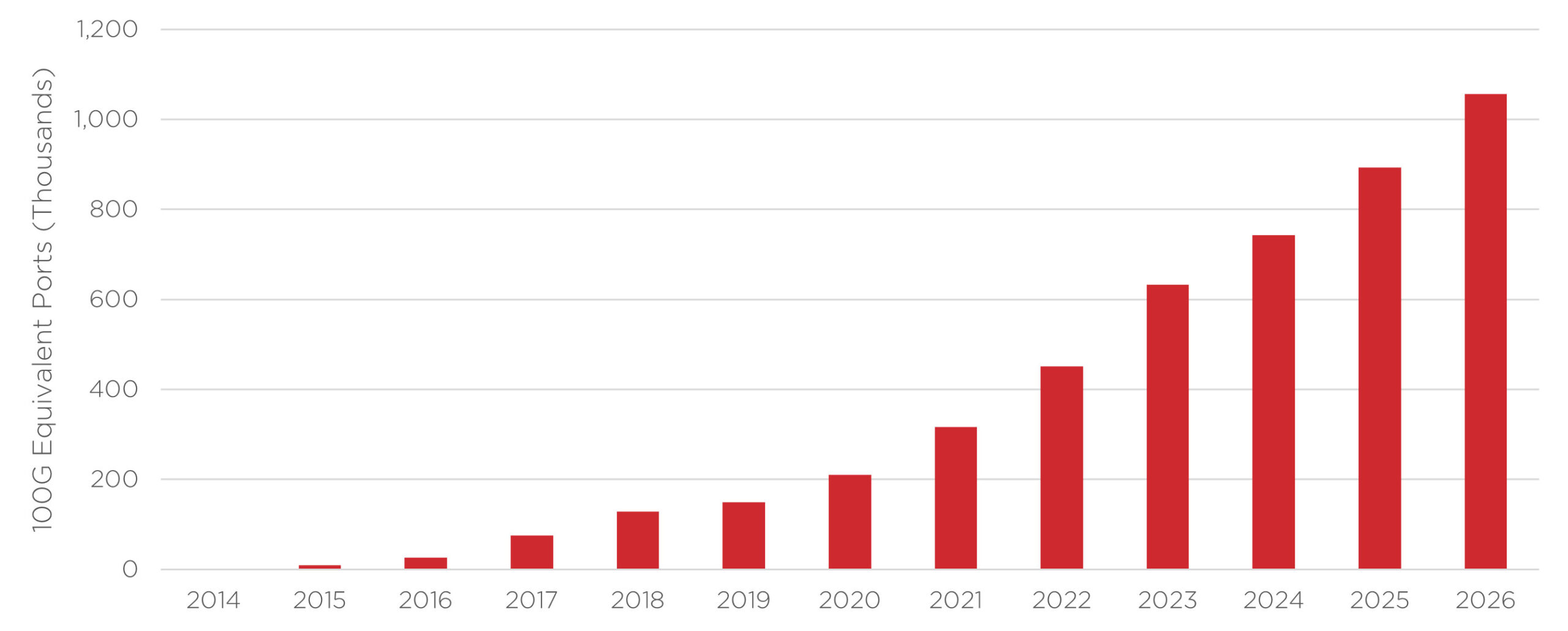

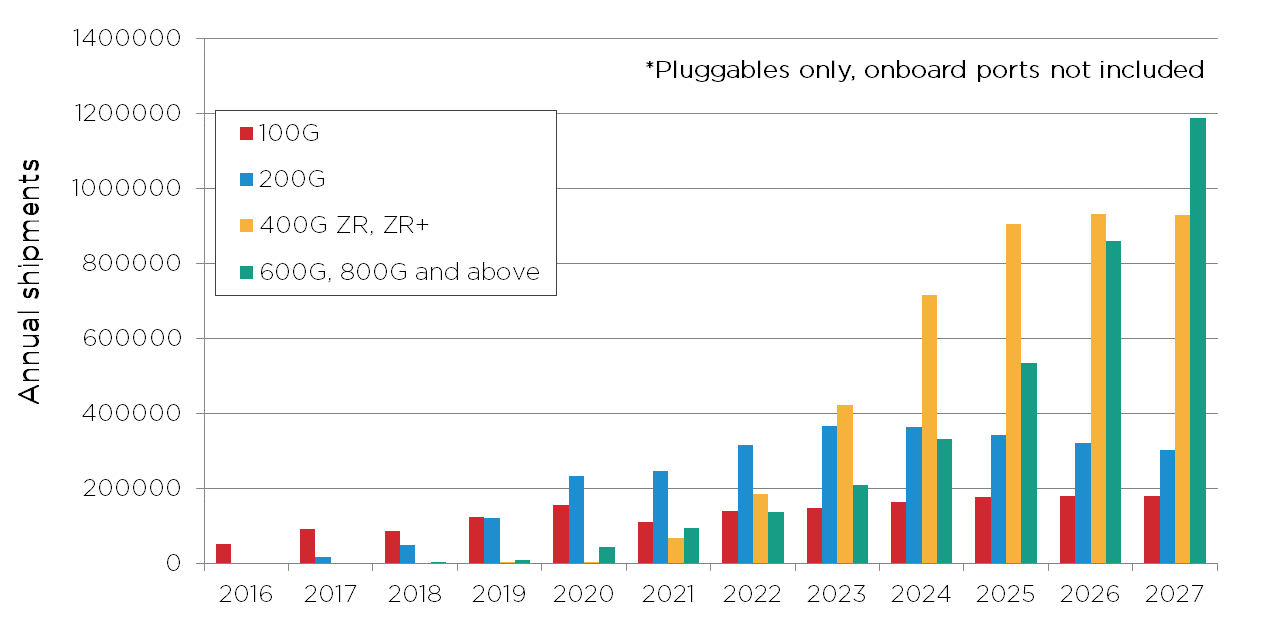

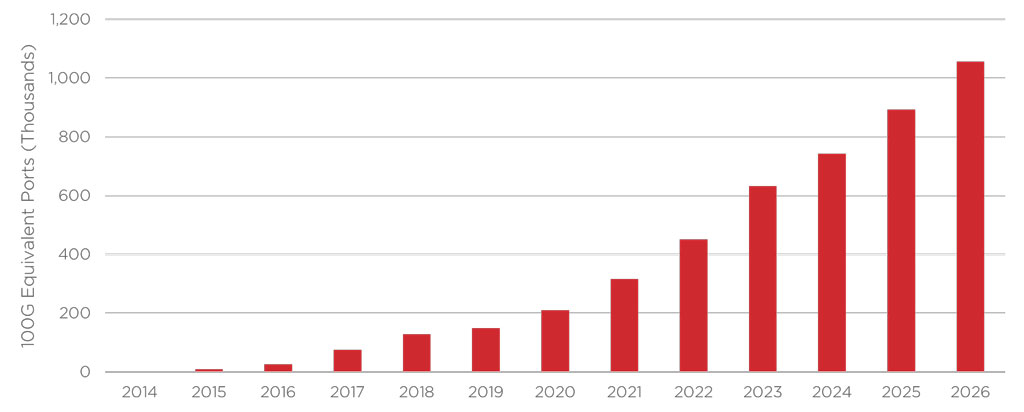

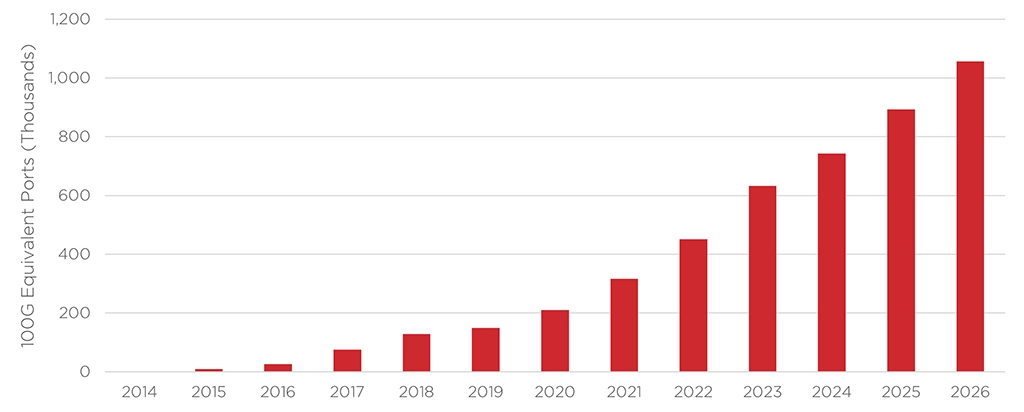

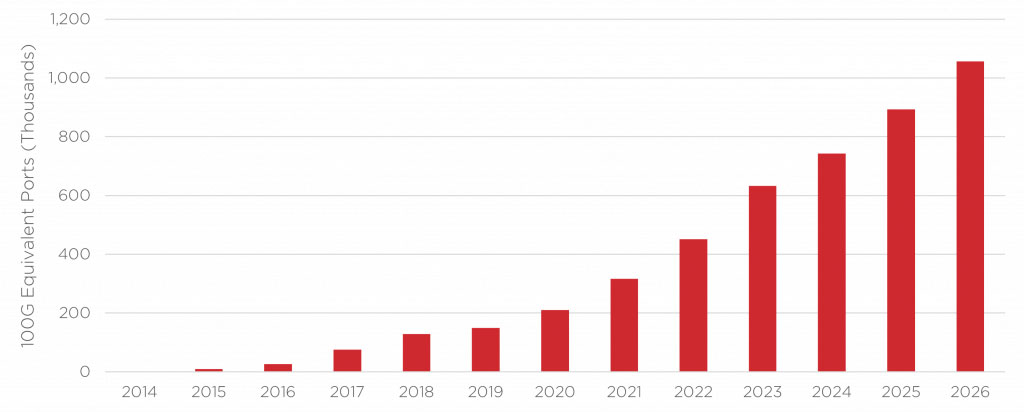

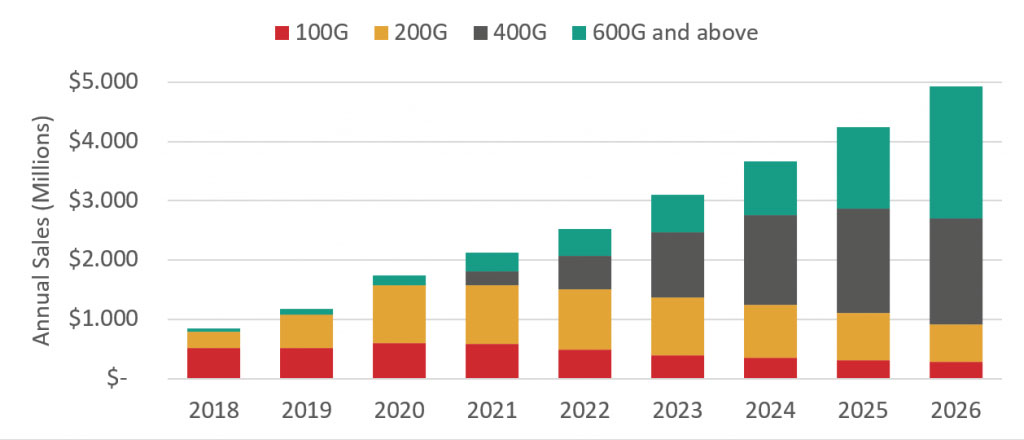

LightCounting forecasts significant growth in dense-wavelength division multiplexing (DWDM) port shipments with data rates of 600G, 800G, and beyond in the next five years.

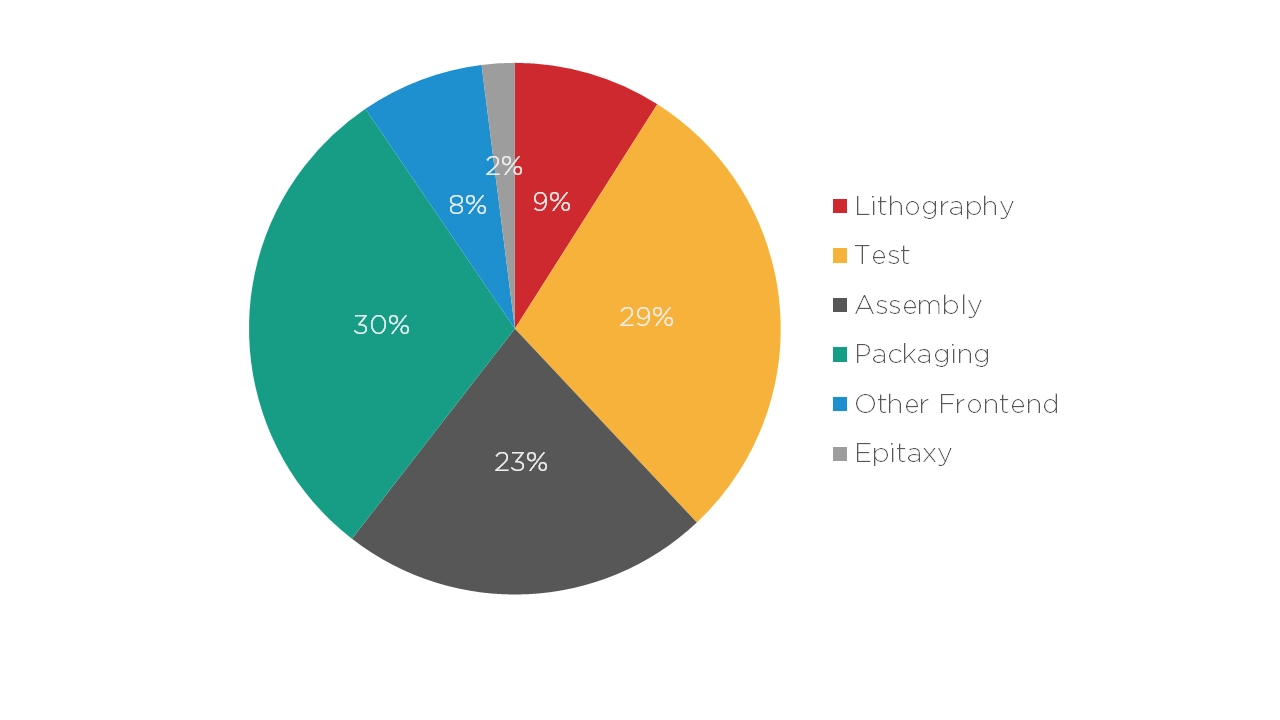

The major obstacles in this roadmap remain transceivers’ power consumption, thermal management, and affordability. Over the last two decades, power ratings for pluggable modules have increased as we moved from direct detection to more power-hungry coherent transmission: from 2W for SFP modules to 3.5 W for QSFP modules and now to 14W for QSSFP-DD and 21.1W for OSFP form factors. Rockley Photonics researchers estimate that a future electronic switch filled with 800G modules would draw around 1 kW of power just for the optical modules.

Thus, many incentives exist to improve pluggable optical transceivers’ performance and power consumption. By embracing increased photonic integration, co-designed PICs and DSPs, and more compact lasers, pluggables will be better able to scale in data rates while remaining affordable and low-power.

What Does This Mean for Lasers and DSPs?

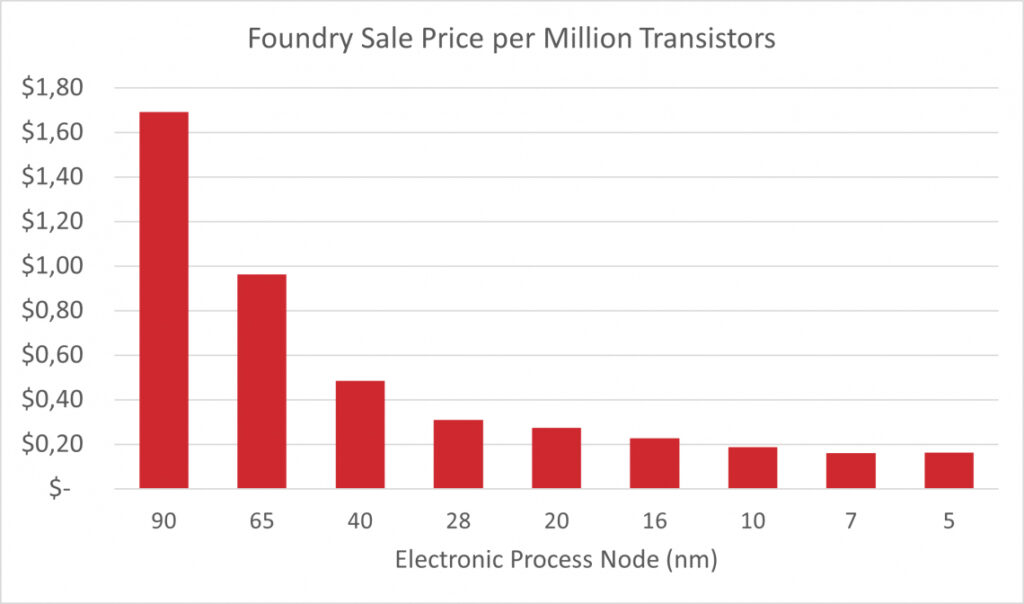

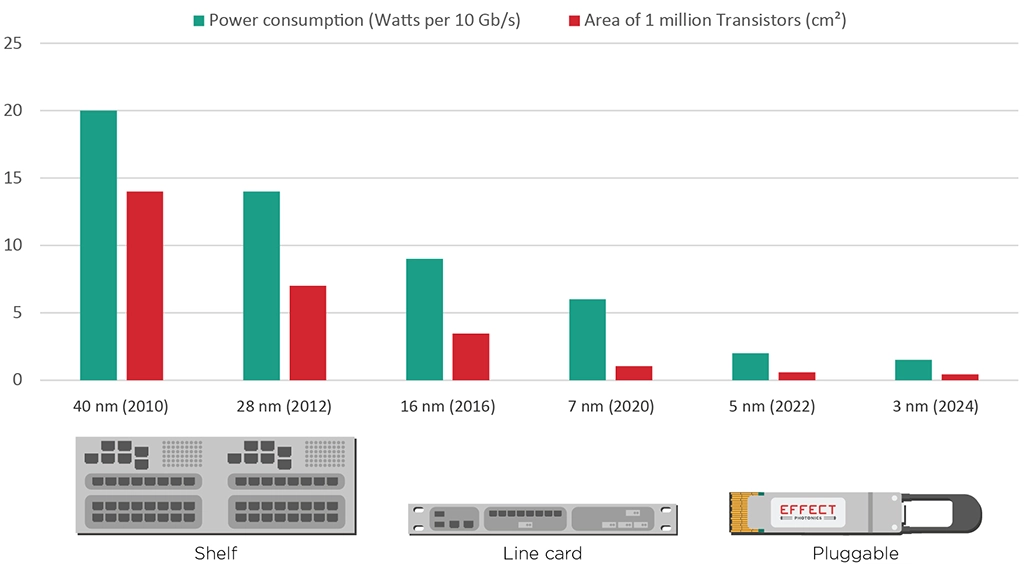

The new generation of 800ZR pluggable transceivers can leverage 5nm process technology for their digital signal processors (DSPs), offering significant advancements over the 7nm technology used in 400ZR transceivers. A primary difference between these two processes lies in the size of the transistors used to build the chips: the 5nm process technology uses smaller transistors than the 7nm process. This size reduction allows more transistors to be packed into the same silicon area, enhancing the chip’s performance and energy efficiency.

For example, this enhanced transistor density facilitates higher baud rates, a critical factor for data transmission. The 800ZR modules will operate at baud rates of 120 GBaud, which doubles the 60 GBaud used in 400ZR transceivers. The increased power efficiency also makes these 800ZR transceivers more suitable for data center environments.

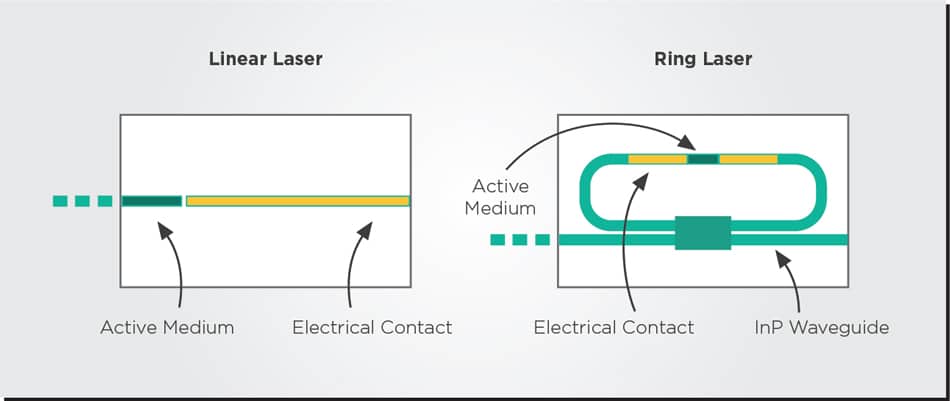

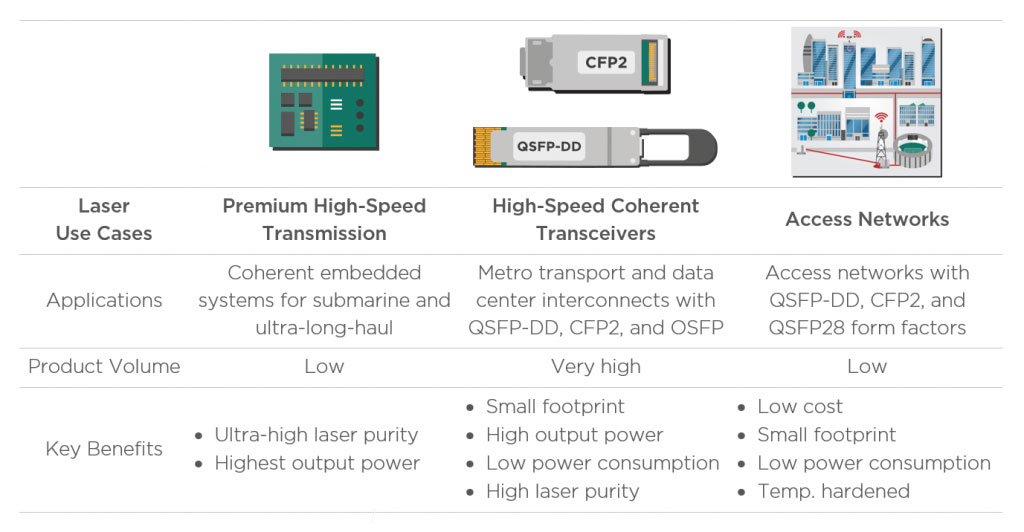

Regarding lasers for 800ZR, the mandate continues to be the same as always: develop the most powerful laser possible with the smallest footprint. Since 800G transmission naturally leads to higher transmission losses than 400G transmission, higher laser power is necessary to compensate for these losses and achieve the required reach. Meanwhile, the smaller laser size helps with thermal management inside the 800ZR module, and high laser power provides a higher link budget.

Takeaways

Following the success of the 400ZR standard, the Optical Internetworking Forum (OIF) quickly moved on to developing 800ZR standards for data center interconnects. The deployment of 800ZR technology promises substantial bandwidth and system performance enhancements but also poses a sustainable solution to the escalating power and thermal challenges modern data centers face. The use of 5nm process technology for DSPs and small but high-performance lasers within these modules will be vital to achieve the required power efficiency and performance.

Tags: 5nm DSPs, 800Gbps, 800ZR technology, Coherent Transceivers, compact lasers, Data center interconnects, DWDM ports, EFFECT Photonics, high-speed transmission, Optical Internetworking Forum, photonic integration, power management, standards

Data Centers in the Age of AI

Article first published 14th June 2023, updated 29th May 2024. Artificial intelligence (AI) is changing…

Article first published 14th June 2023, updated 29th May 2024.

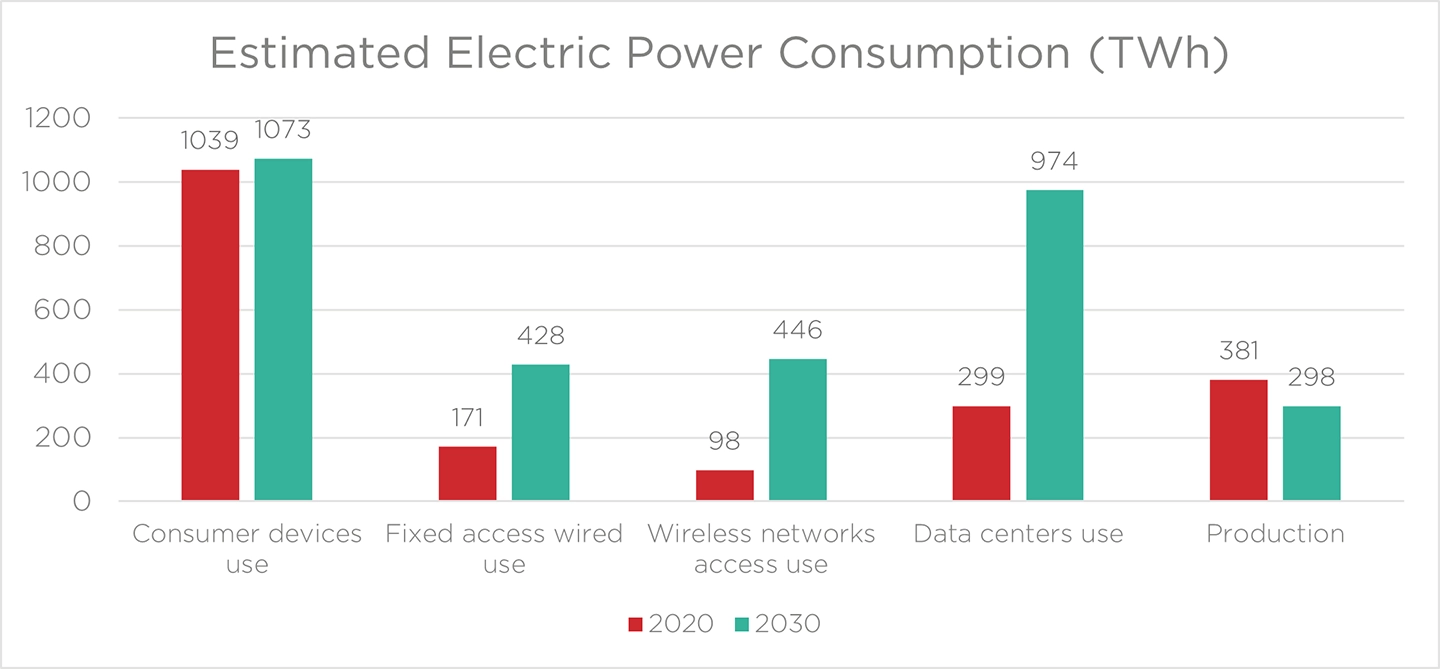

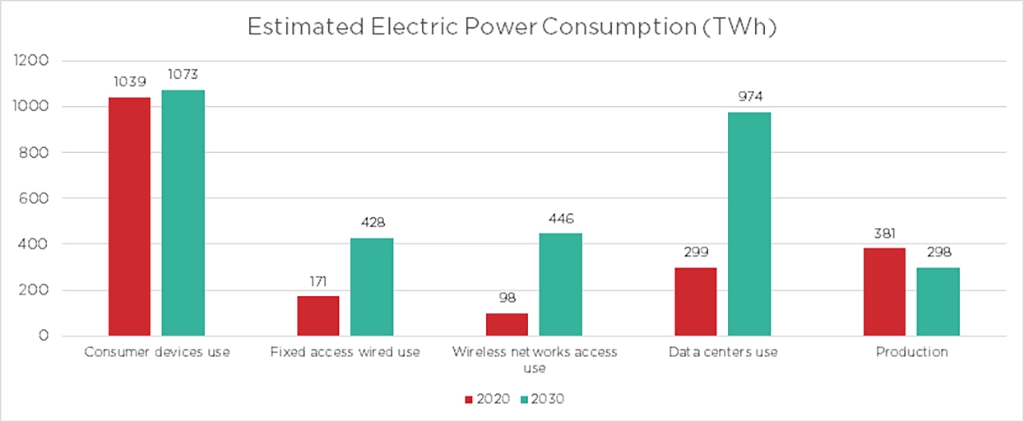

Artificial intelligence (AI) is changing the technology landscape in various industries, and data centers are no exception. AI algorithms are computationally heavy and will increase data centers’ power consumption and cooling requirements, deeply affecting data center infrastructure.

The Constraints of the Power Grid

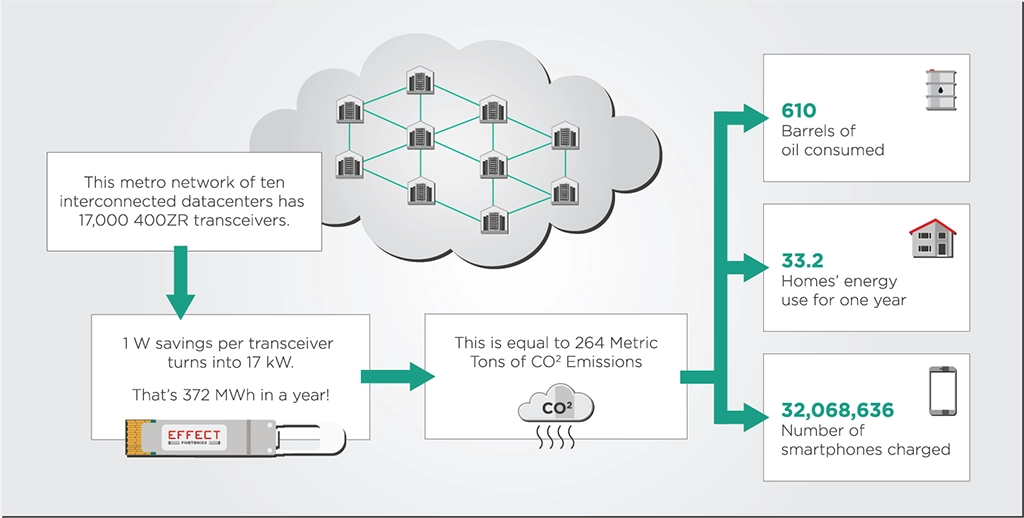

Data centers famously consume a significant amount of energy, and power-hungry AI algorithms will lead to a further increase in data center power consumption. The world’s major data center providers are already gearing up for this increase. For example, a recent Reuters report explains how Meta computing clusters needed 24 to 32 times the networking capacity. This increase required redesigning the clusters and data centers to include new liquid cooling systems.

Despite the best efforts of the world’s tech giants to rethink their architectures, it’s clear that data centers and their new AI workloads are hitting electrical power grid limitations. The capacity of the power grid is now increasingly regarded as the main chokepoint that prevents AI clusters from being more widely implemented in data centers.

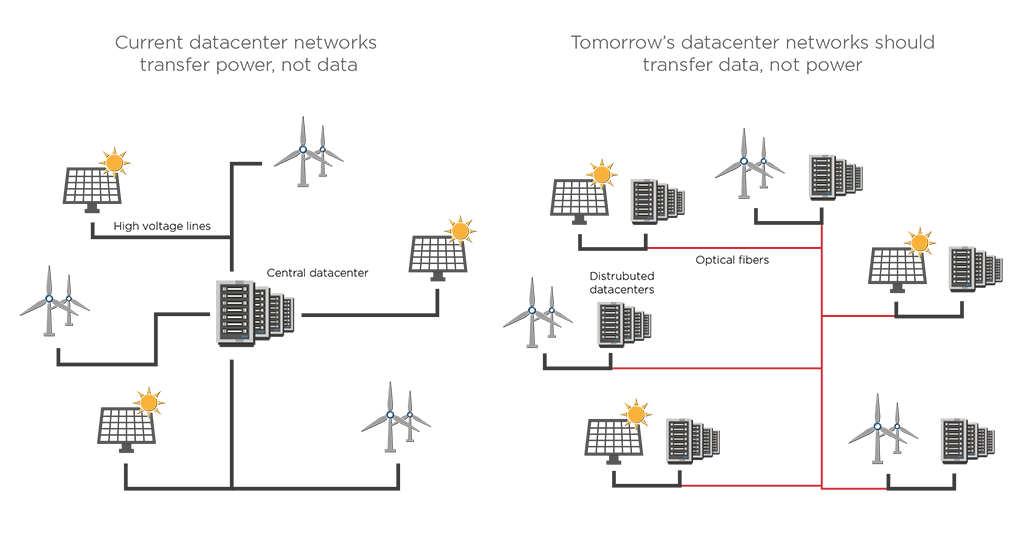

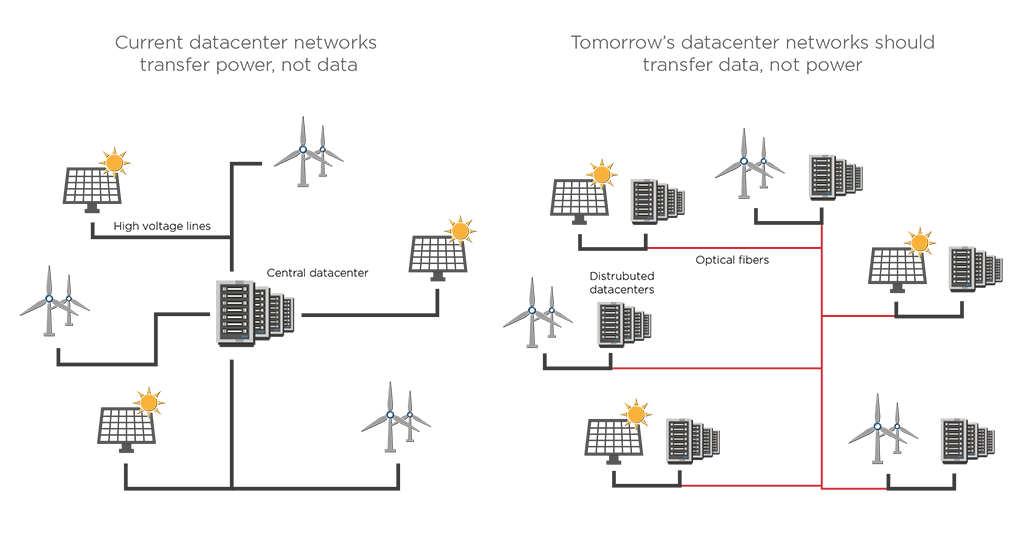

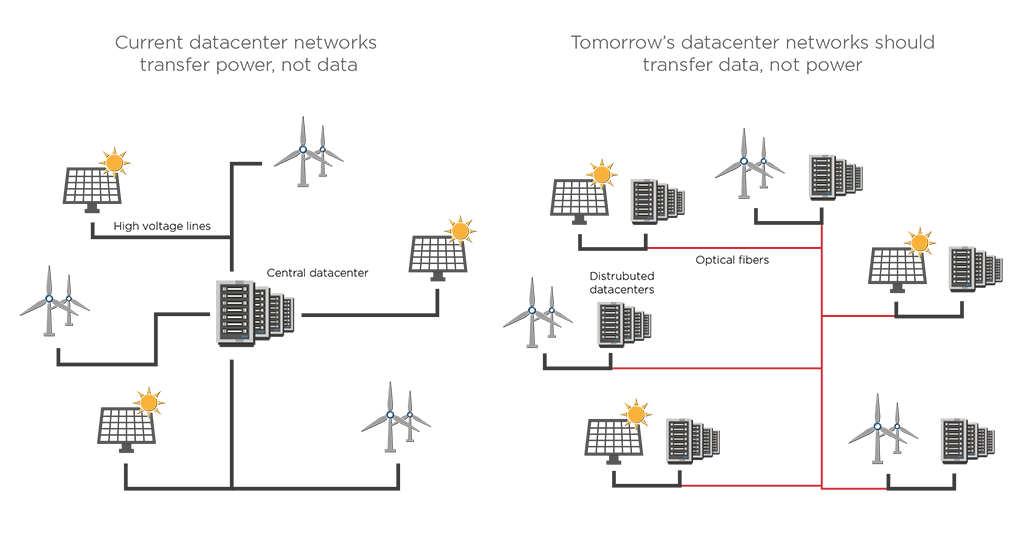

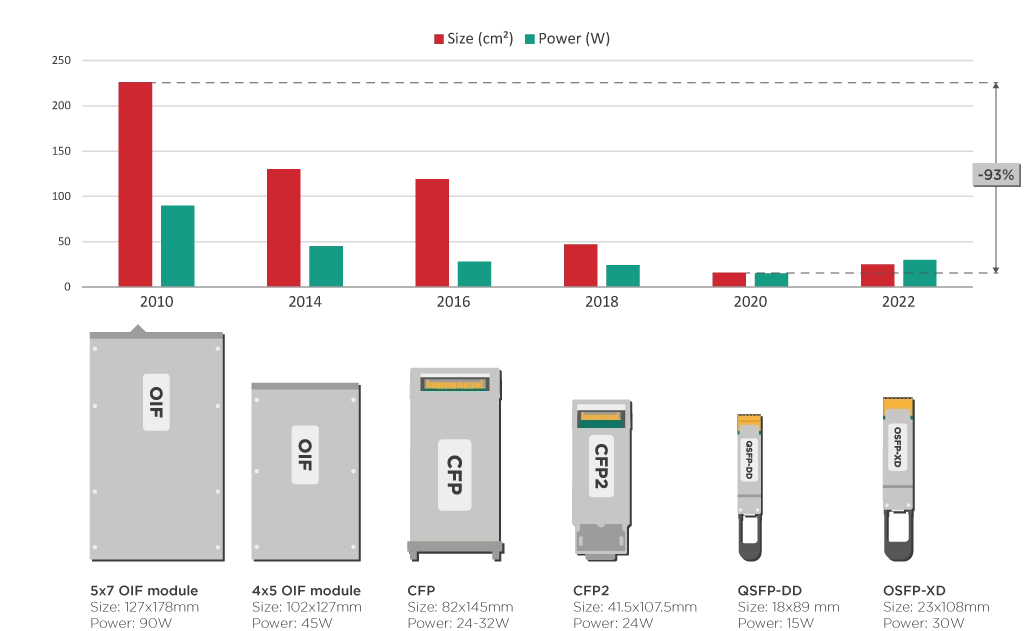

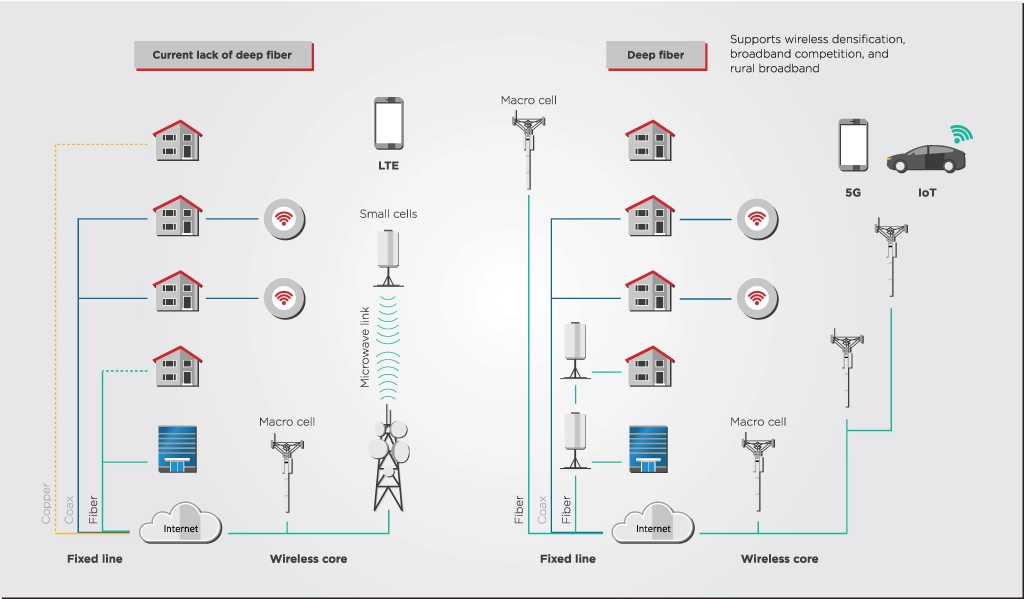

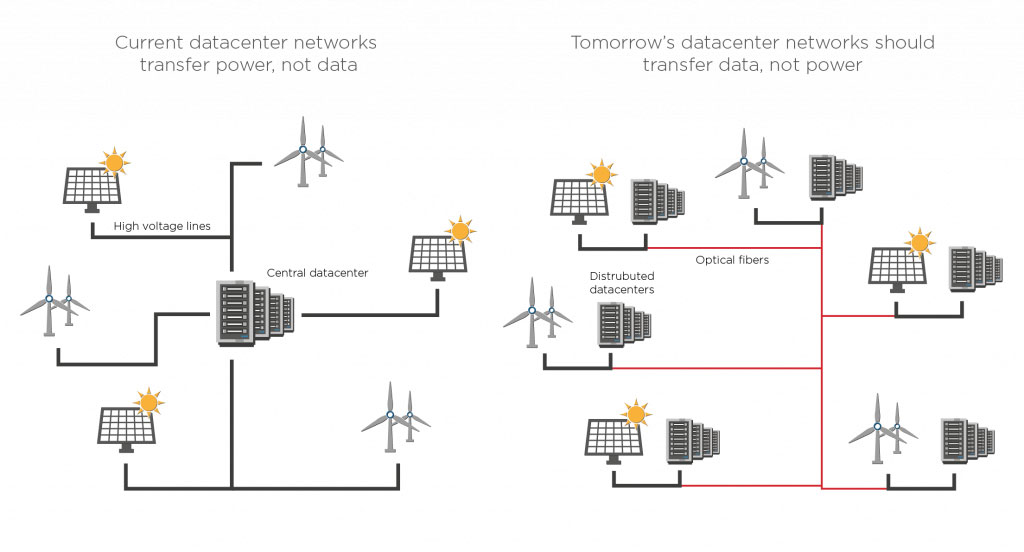

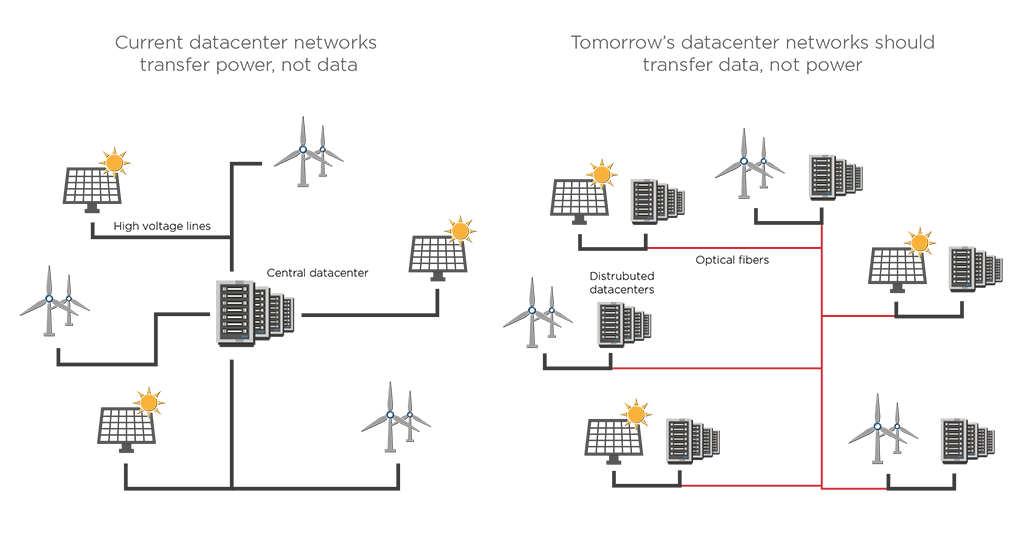

Since changes in the power grid distribution would take decades to materialize, data center providers know they cannot continue to centralize their data center architectures. To adapt to the power grid constraints, providers are thinking about how to transfer data between decentralized data center locations instead.

For example, data centers can relocate to areas with available spare power, preferably from nearby renewable energy sources. Efficiency can increase further by sending data to branches with spare capacity. The Dutch government has already proposed this kind of decentralization as part of its spatial strategy for data centers.

Interconnecting Data Centers over Long Distances

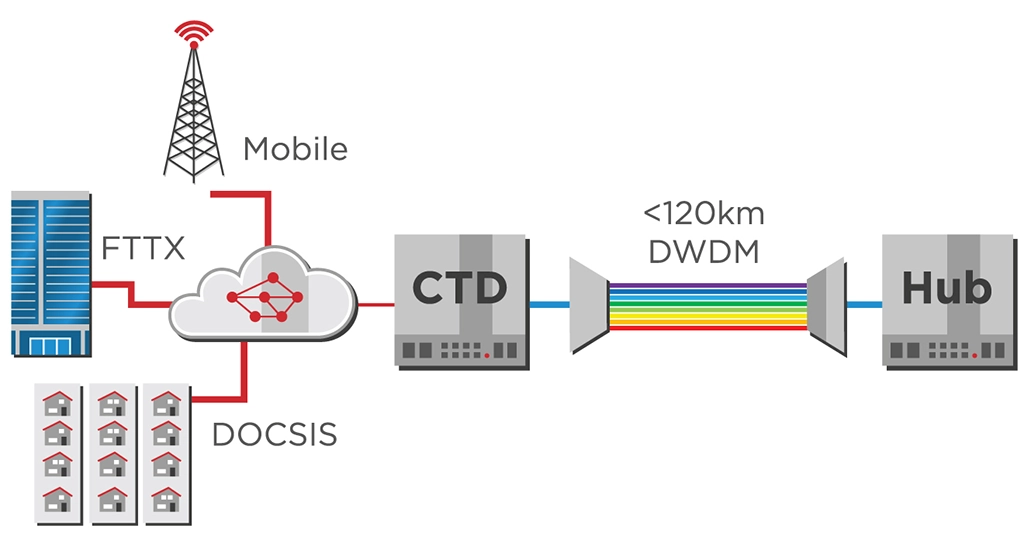

Longer data center interconnects enable a more decentralized system of data centers with branches in different geographical areas connected through high-speed optical fiber links to cope with the strain of data center clusters on power grids.

These trends push the data center industry to look for interoperable solutions for longer interconnects over 80 to 120 km distances. The advances in electronic and photonic integration allowed coherent technology for metro DCIs to be miniaturized into QSFP-DD and OSFP form factors. This progress allowed the Optical Internetworking Forum (OIF) to create the 400ZR and ZR+ standards for 400G DWDM pluggable modules. With modules that are small enough to pack a router faceplate densely, the datacom sector could profit from a 400ZR solution for high-capacity data center interconnects of up to 80km.

After the success of 400ZR standardization, the data center industry and the OIF are starting to promote an 800ZR standard to enable the next generation of interconnects. In OFC 2024, we started seeing some demos from several vendors and the OIF on this new standards initiative.

Optical Interconnects Inside Data Centers

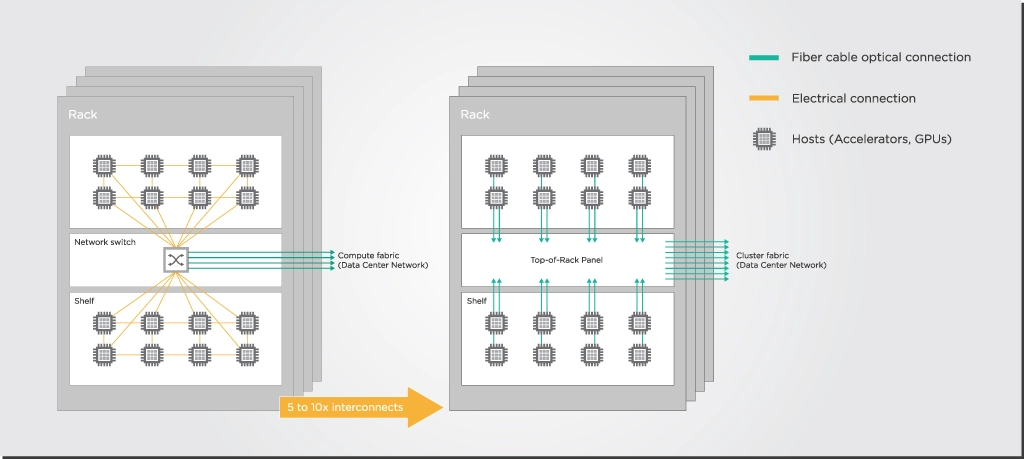

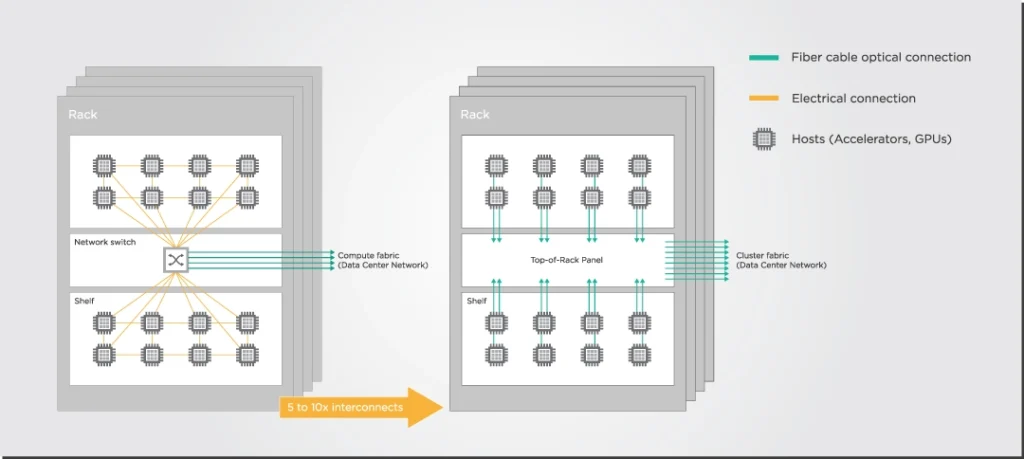

The increasing complexity of AI processing will impact not just the interconnections between data centers but also the architectures inside the data center. AI nodes inside data center racks are normally connected via electrical or RF signals, while the racks are connected via optical fiber interconnects. However, as AI systems do more parallelized processing, data center racks run into electrical memory and power consumption constraints. These electrical interconnects between AI nodes are increasingly becoming a bottleneck in the ability of data center architectures to scale and handle the demands of AI models sustainably.

Optics will play an increasingly larger role in this area. As explained by Andrew Alduino and Rob Stone of Meta in a talk at the 2022 OCP Global Summit, interconnecting AI nodes via optics will be vital to decreasing the power per bit transmitted inside data center racks. This means changing the traditional architecture inside these racks. Instead of using an electro-optical switch that converts the electrical interconnects between AI nodes to optical interconnects with another, the switching inside the data center rack would be entirely optical.

Avoiding the power losses of electrical connections and electrical-optical conversions will improve the cost and power per bit of connections inside the data center. As more data center capacity is needed, these new optical interconnections might also need co-packaged coherent optics to scale effectively. This is the argument made recently by our very own Joost Verberk, EFFECT Photonics’ VP of Product Management, at the 2024 OCP Regional Summit in Lisbon.

Takeaways

As AI continues reshaping the technological infrastructure, data centers undergo significant transformations to meet the new demands. The shift towards AI-intensive operations has exacerbated the existing strain on power grids, pushing data center providers towards more decentralized solutions. This includes relocating to areas with spare power and transferring data with optical interconnects across geographically dispersed locations.

The adoption of advanced optical interconnections is happening also inside data centers, as data center racks might transition to all-optical switching to connect their AI nodes. These evolving strategies not only address the immediate challenges of AI workloads but also set the stage for more sustainable and scalable data center operations in the future.

Tags: Artificial intelligence (AI), Cooling requirements, Data center architecture, data centers, energy efficiency, Intelligent automation, Networking capacity, Optimal temperature and airflow, power consumption, Power usage effectiveness (PUE) ratio

Why Semiconductors are Vital to Optics and Photonics

Thanks to wafer-scale technology, electronics have driven down the cost per transistor for many decades.…

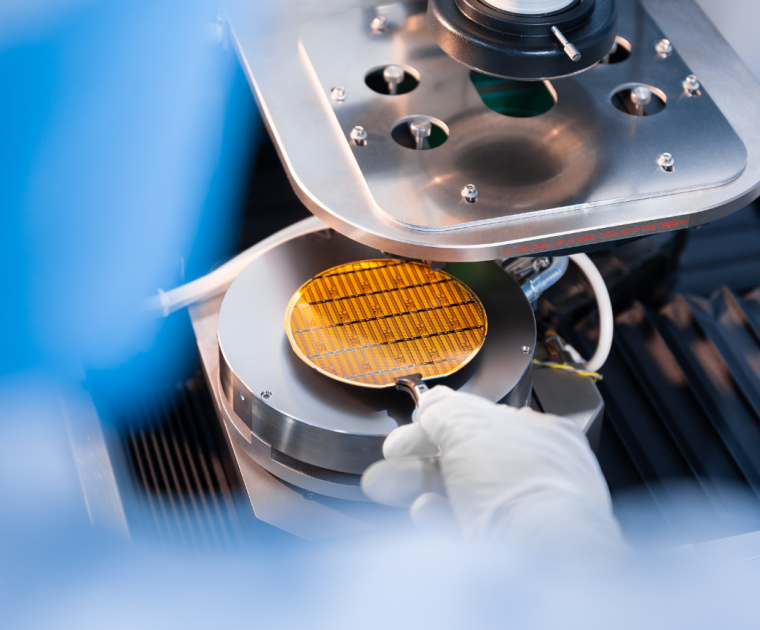

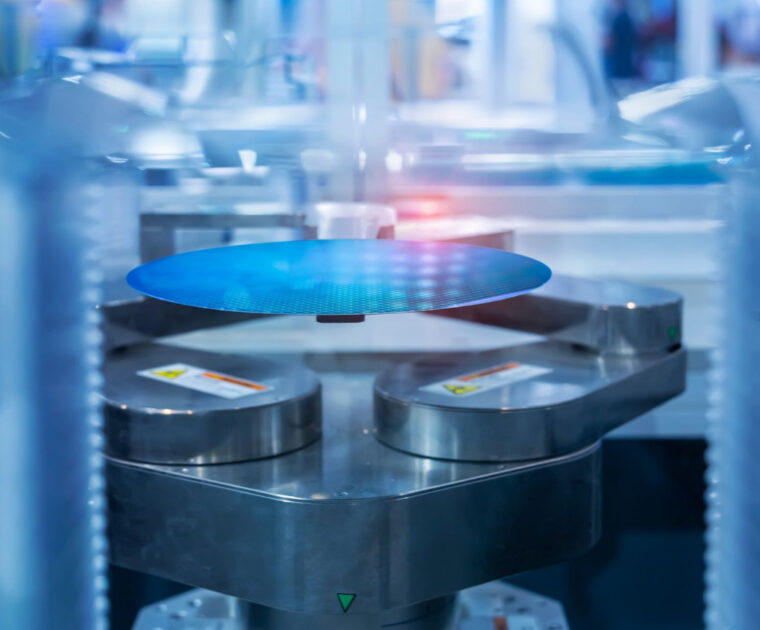

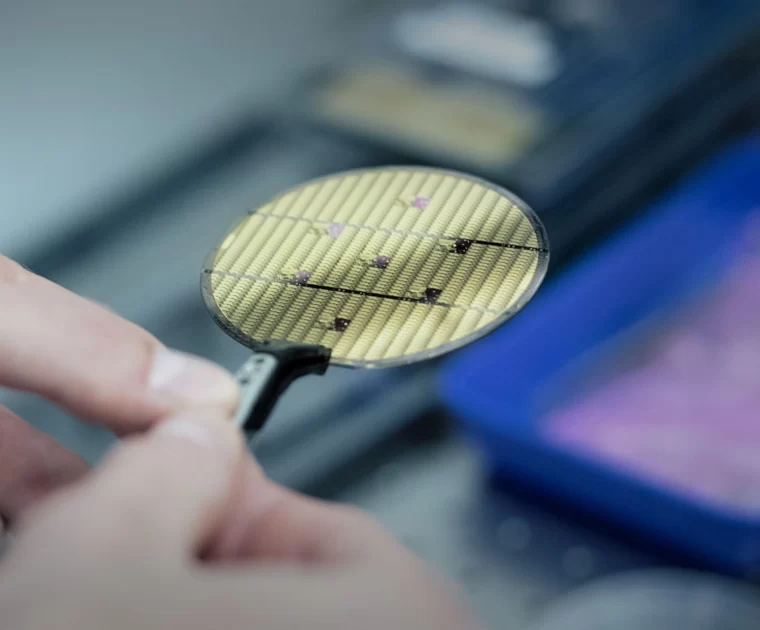

Thanks to wafer-scale technology, electronics have driven down the cost per transistor for many decades. This allowed the world to enjoy chips that every generation became smaller and provided exponentially more computing power for the same amount of money. This scale-up process is how everyone now has a computer processor in their pocket that is millions of times more powerful than the most advanced computers of the 1960s that landed men on the moon.

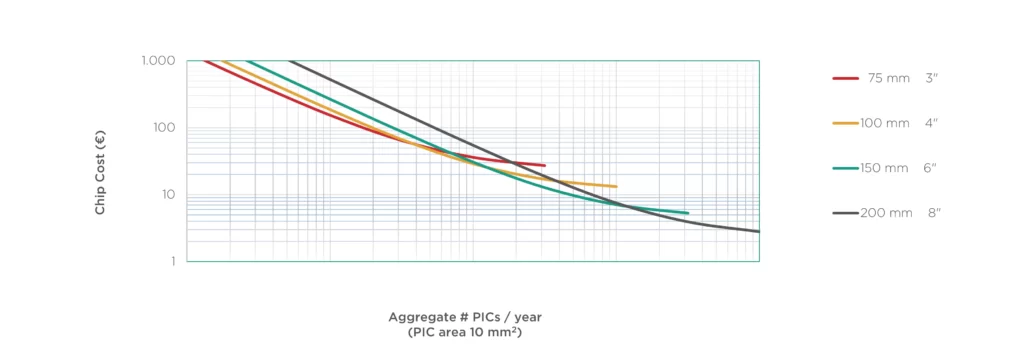

For example, this progress in electronics integration is a key factor that brought down the size and cost of coherent transceivers, packing more bits than ever into smaller areas. However, photonics has struggled to keep up with electronics, with the photonic components dominating the cost of transceivers. Making transceivers more accessible across the entire optical network requires bringing down these costs.

In this article, we will explore a bit of the relationship between optics and semiconductors and explain what optics can learn from electronics when it comes to semiconductor processes.

At the Heart of Photonic Systems

Semiconductor materials are vital for photonics due to their electronic and optical properties. These materials have a bandgap that can be precisely manipulated to control the absorption and emission of light, and this is essential for creating photonic devices like lasers and photodetectors. The ability to engineer the electronic structure of semiconductors like silicon, gallium arsenide (GaAs), and indium phosphide (InP) allows for the design of devices that operate across various wavelengths of light. These capabilities allow us to develop efficient, compact, and versatile photonic components.

Moreover, semiconductor fabrication techniques, inherited from the microelectronics industry, enable the mass production of photonic devices, which supports scalability and integration of photonics with existing electronic systems. If photonics becomes as readily available and easy to use as electronics, it can become more widespread and have an even greater impact on the world.

“We need to buy photonics from a catalog as we do with electronics, have datasheets that work consistently, be able to solder it to a board and integrate it easily with the rest of the product design flow.“

Tim Koene – Chief Technology Officer, EFFECT Photonics

Some differences between electronics and photonics complicate this transition. Silicon, the dominant material in microelectronics, cannot naturally emit laser light from electrical signals. Therefore, making suitable components for integrated photonics often requires using III-V semiconductor materials such as InP and GaAs. The need for these non-silicon semiconductors has made the photonics manufacturing space harder to standardize and streamline than microelectronics.

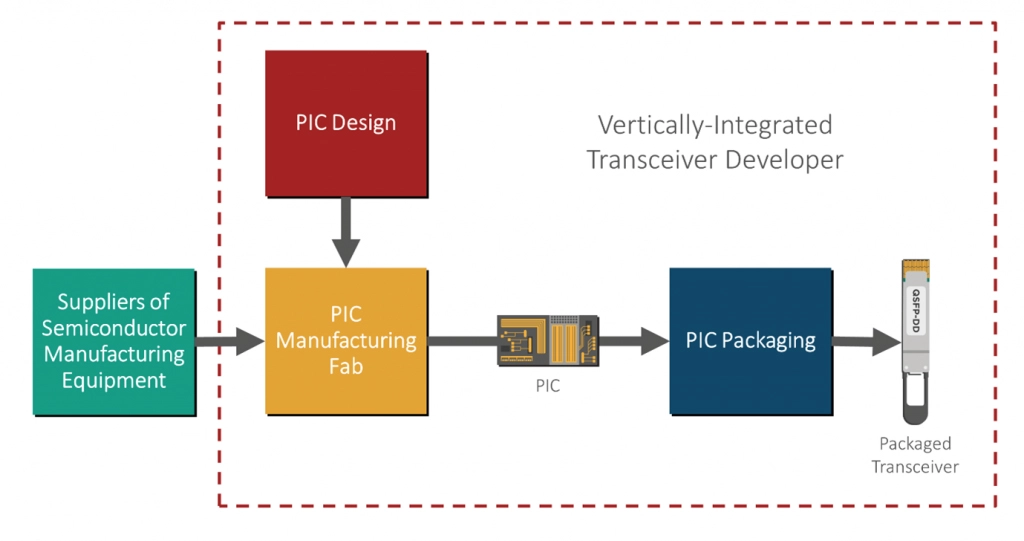

The Need for a Fabless Model

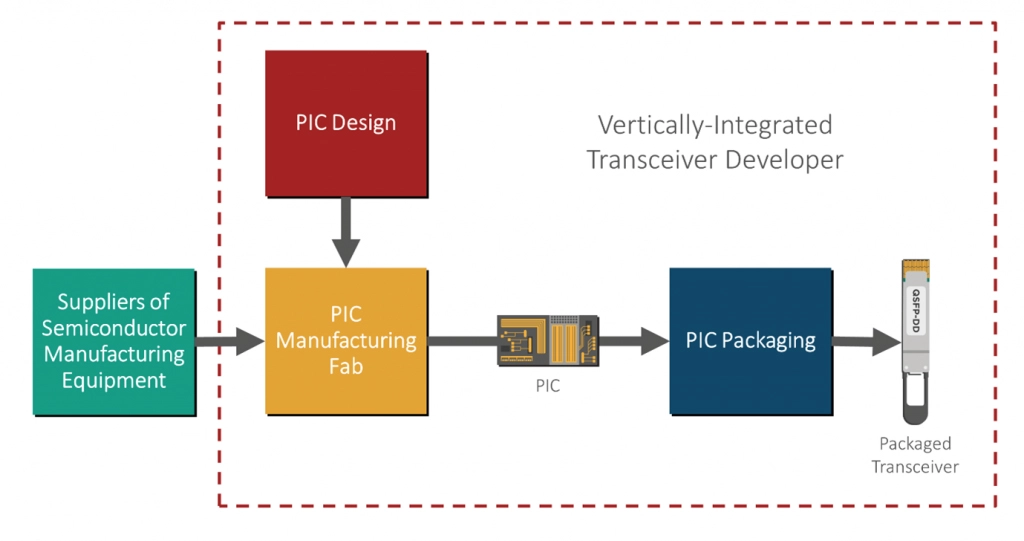

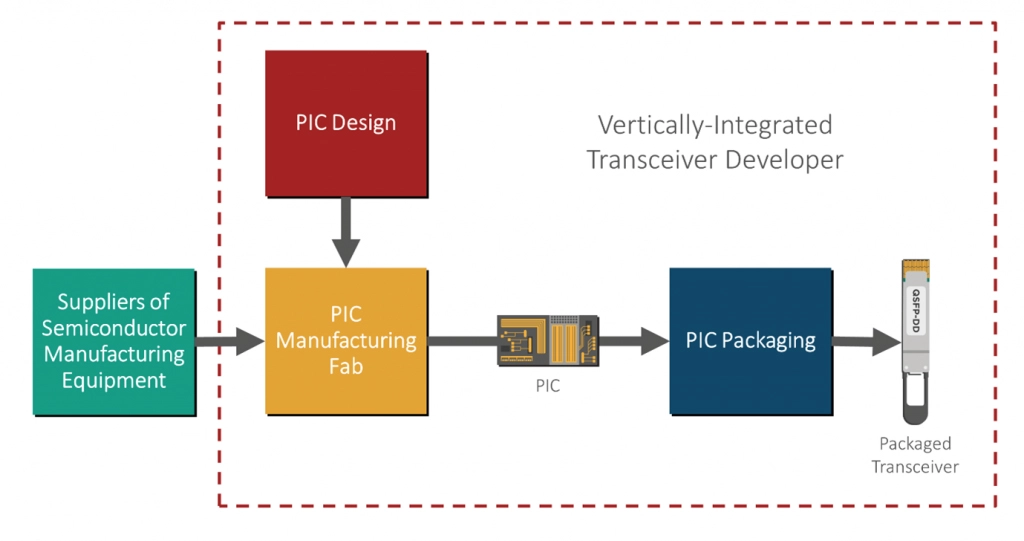

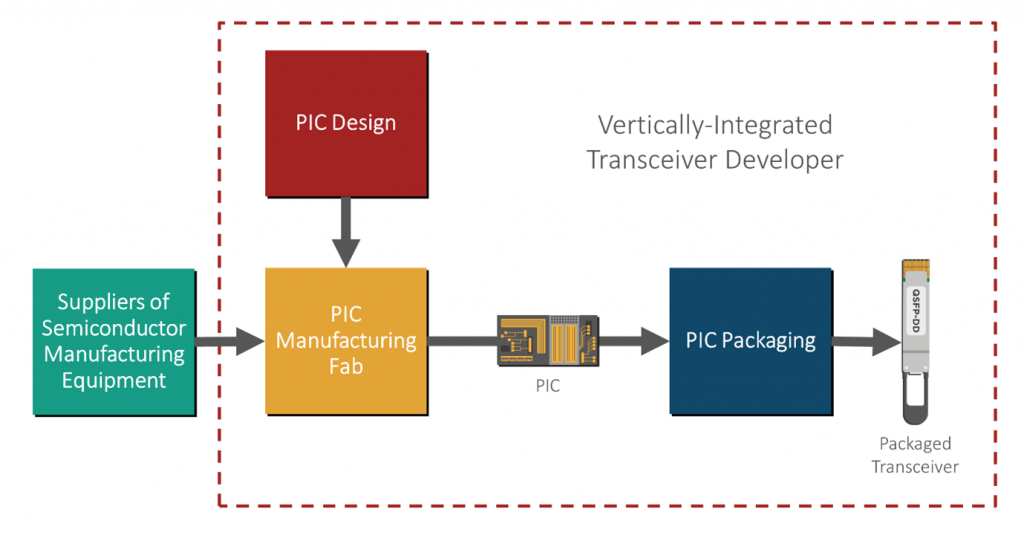

Increasing the volume of photonics manufacturing is a big challenge. Some photonic chip developers manufacture their chips in-house within their fabrication facilities. This approach has some substantial advantages, giving component manufacturers complete control over their production process.

However, this approach has its trade-offs when scaling up. If a vertically-integrated chip developer wants to scale up in volume, they must make a hefty capital expenditure (CAPEX) in more equipment and personnel. They must develop new fabrication processes as well as develop and train personnel. Fabs are not only expensive to build but to operate. Unless they can be kept at nearly full utilization, operating expenses (OPEX) also drain the facility owners’ finances.

Especially in the case of an optical transceiver market that is not as big as that of consumer electronics, it’s hard not to wonder whether that initial investment is cost-effective. For example, LightCounting estimates that 55 million optical transceivers were sold in 2021, while the International Data Corporation estimates that 1.4 billion smartphones were sold in 2021. The latter figure is 25 times larger than that of the transceiver market.

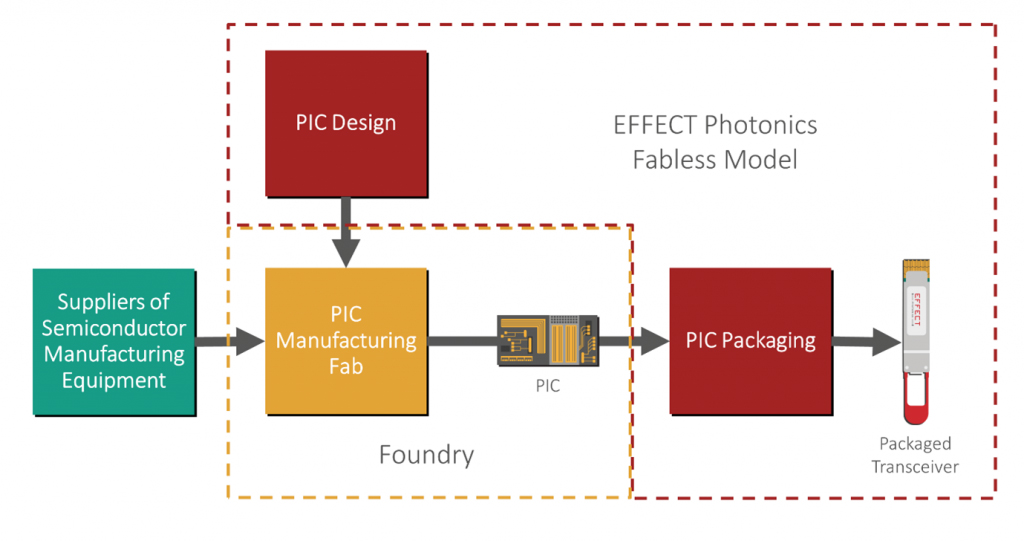

Electronics manufacturing experienced a similar problem during their 70s and 80s boom, with smaller chip start-ups facing almost insurmountable barriers to market entry because of the massive CAPEX required. Furthermore, the large-scale electronics manufacturing foundries had excess production capacity that drained their OPEX. The large-scale foundries ended up selling that excess capacity to the smaller chip developers, who became fabless. In this scenario, everyone ended up winning. The foundries serviced multiple companies and could run their facilities at total capacity, while the fabless companies could outsource manufacturing and reduce their expenditures.

This fabless model, with companies designing and selling the chips but outsourcing the manufacturing, should also be the way to go for photonics. Instead of going through a more costly, time-consuming process, the troubles of scaling up for photonics developers are outsourced and (from the perspective of the fabless company) become as simple as putting a purchase order in place. Furthermore, the fabless model allows photonics developers to concentrate their R&D resources on the end market. This is the simplest way forward if photonics moves into million-scale volumes.

Investment is Needed for Photonics to Scale like Electronics

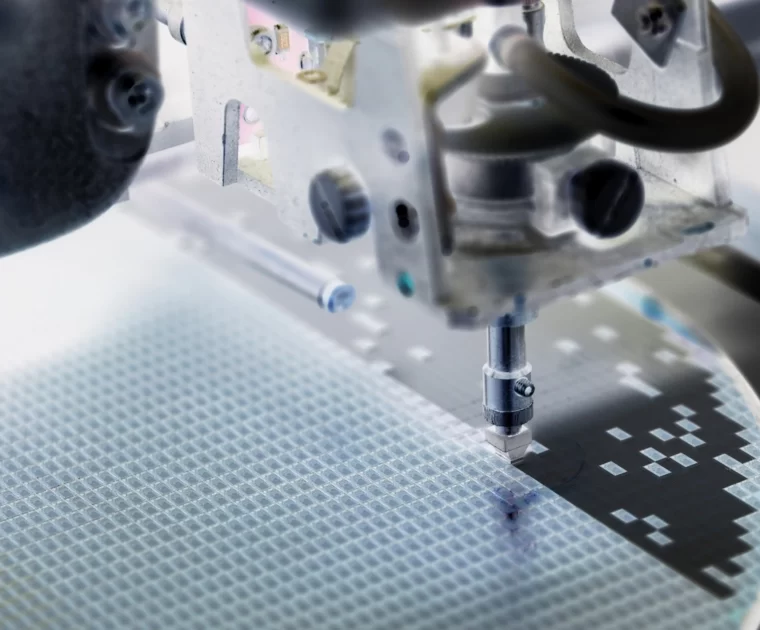

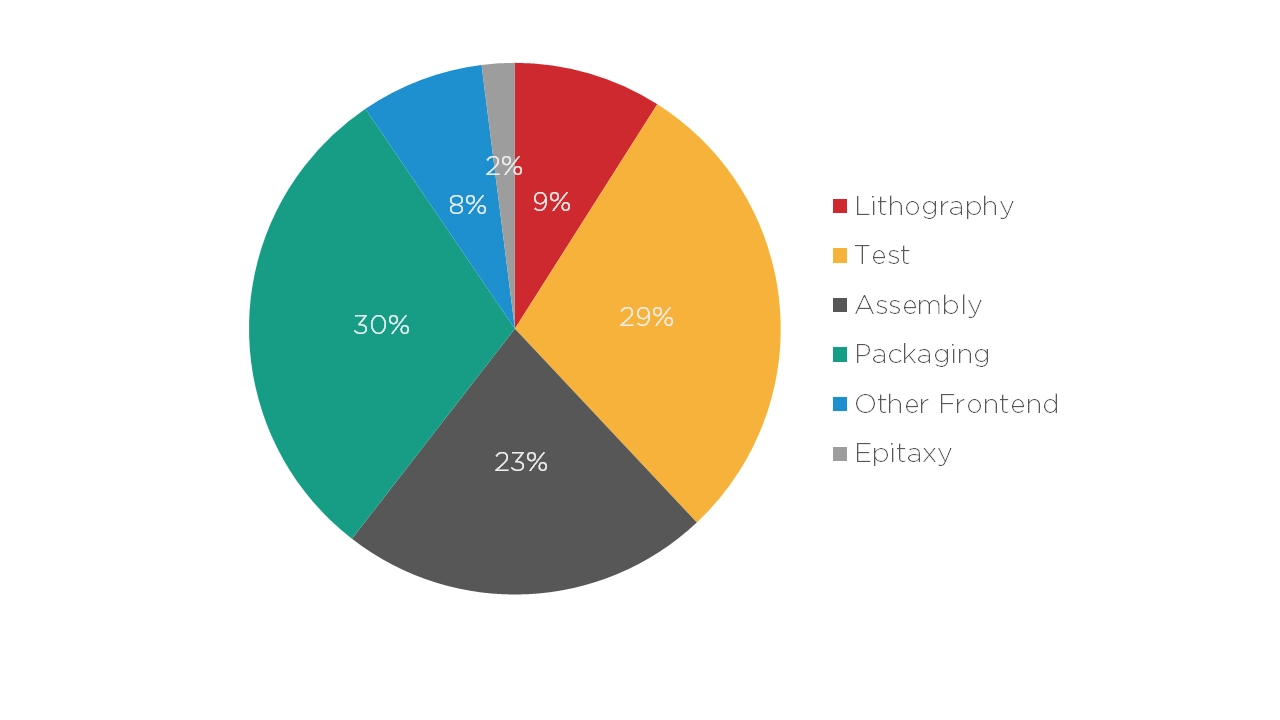

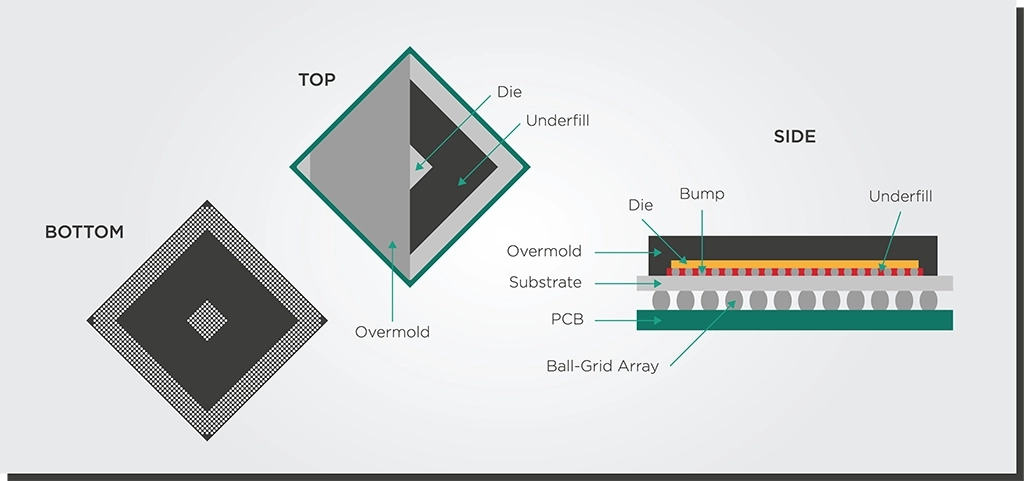

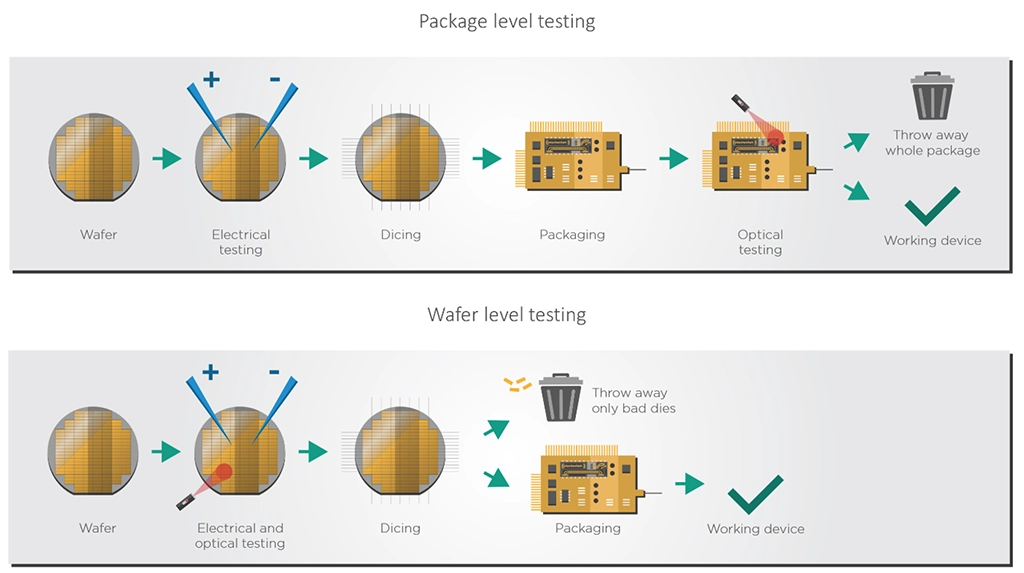

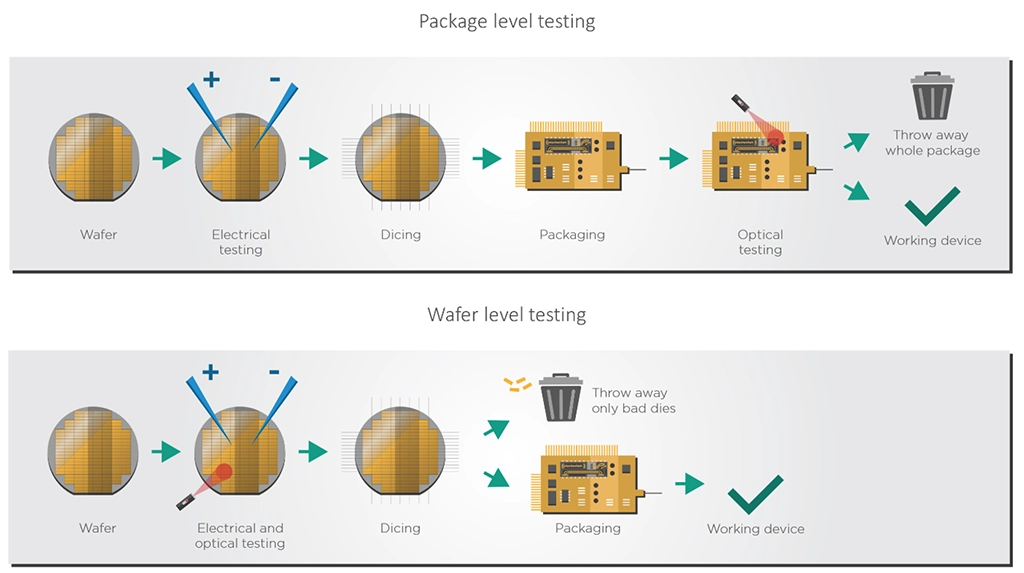

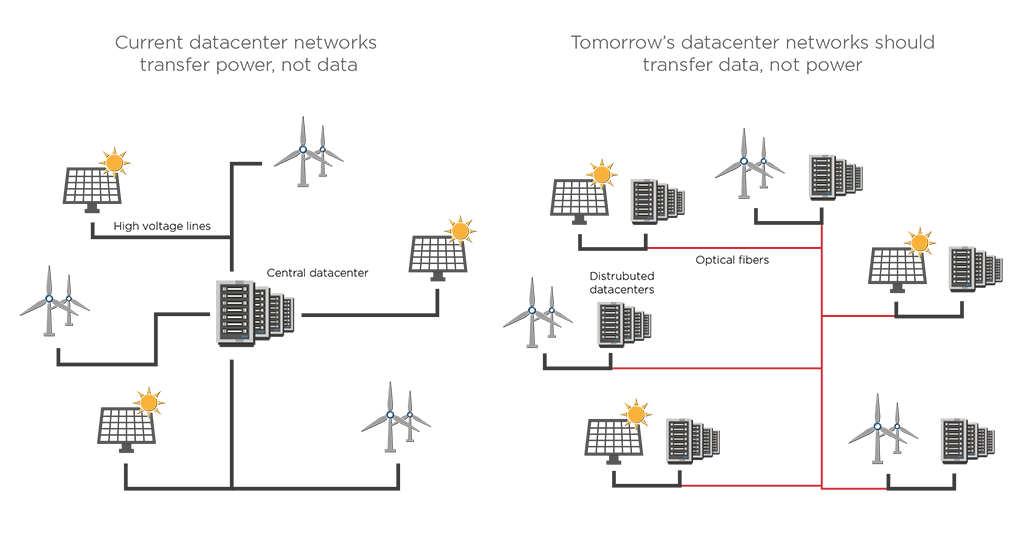

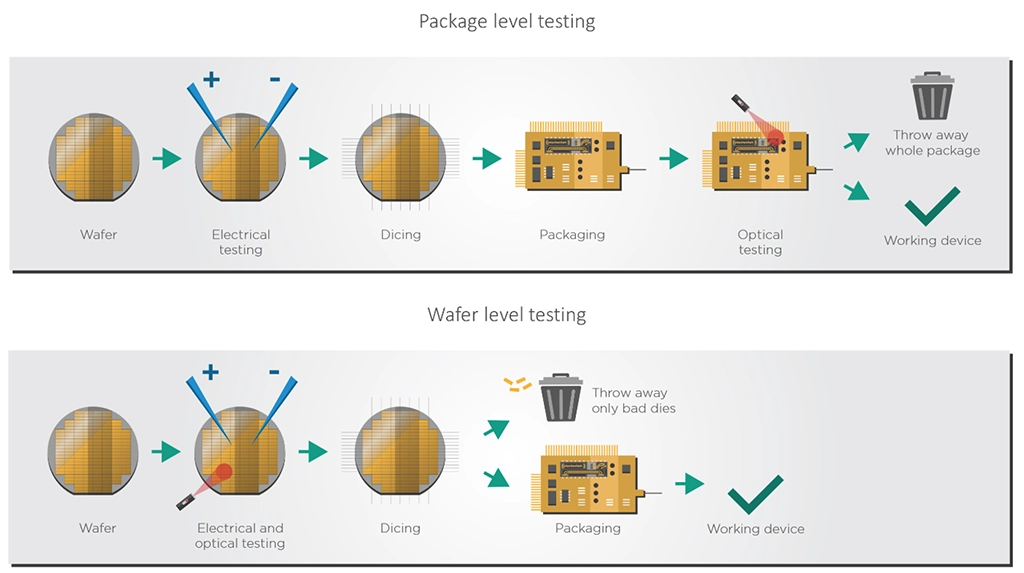

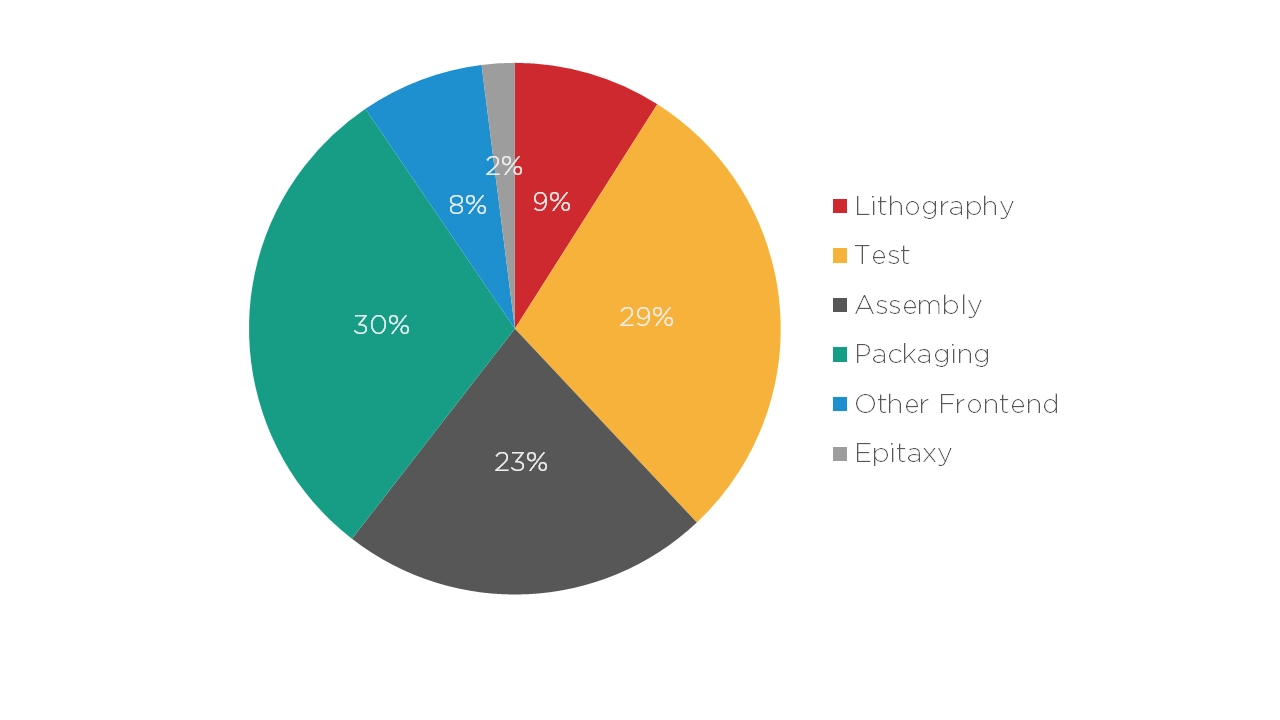

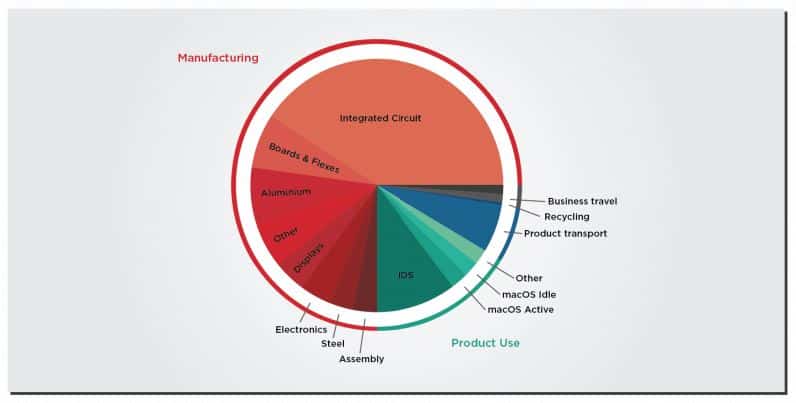

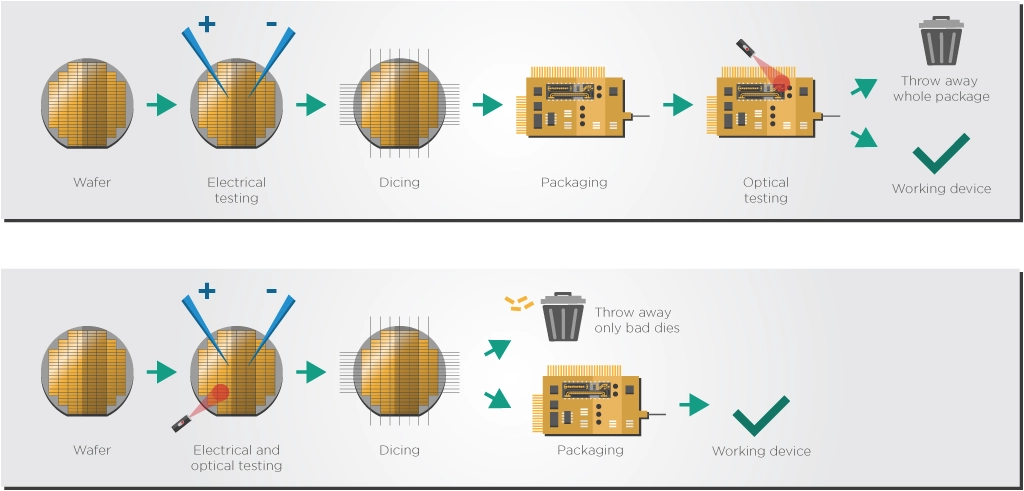

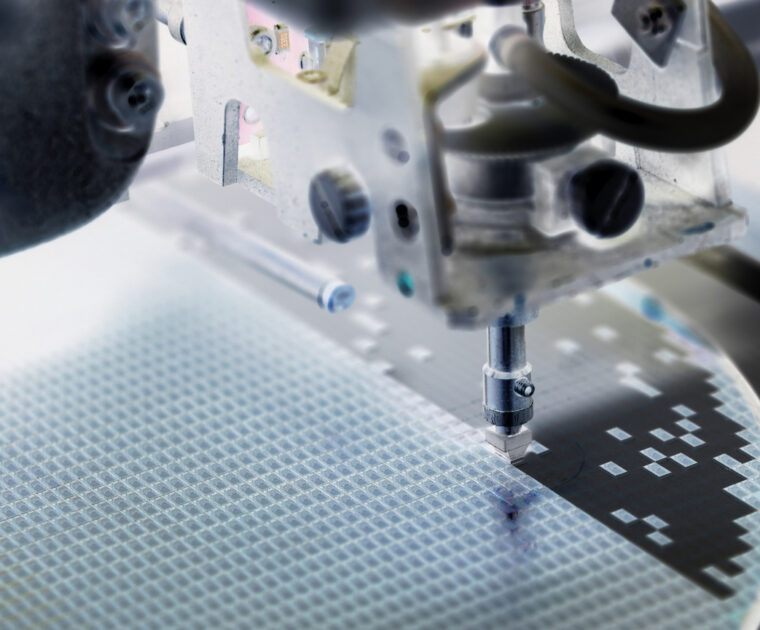

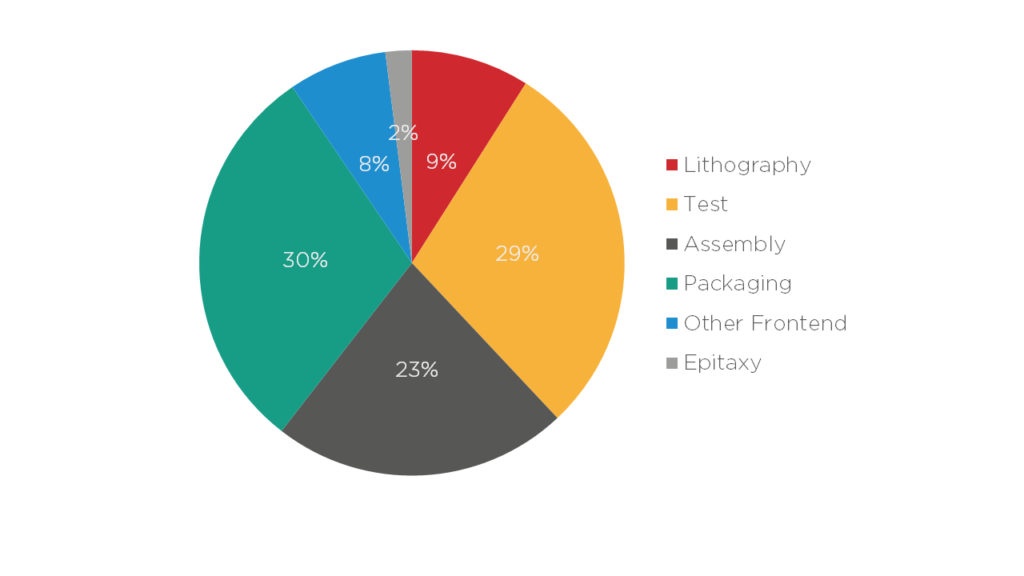

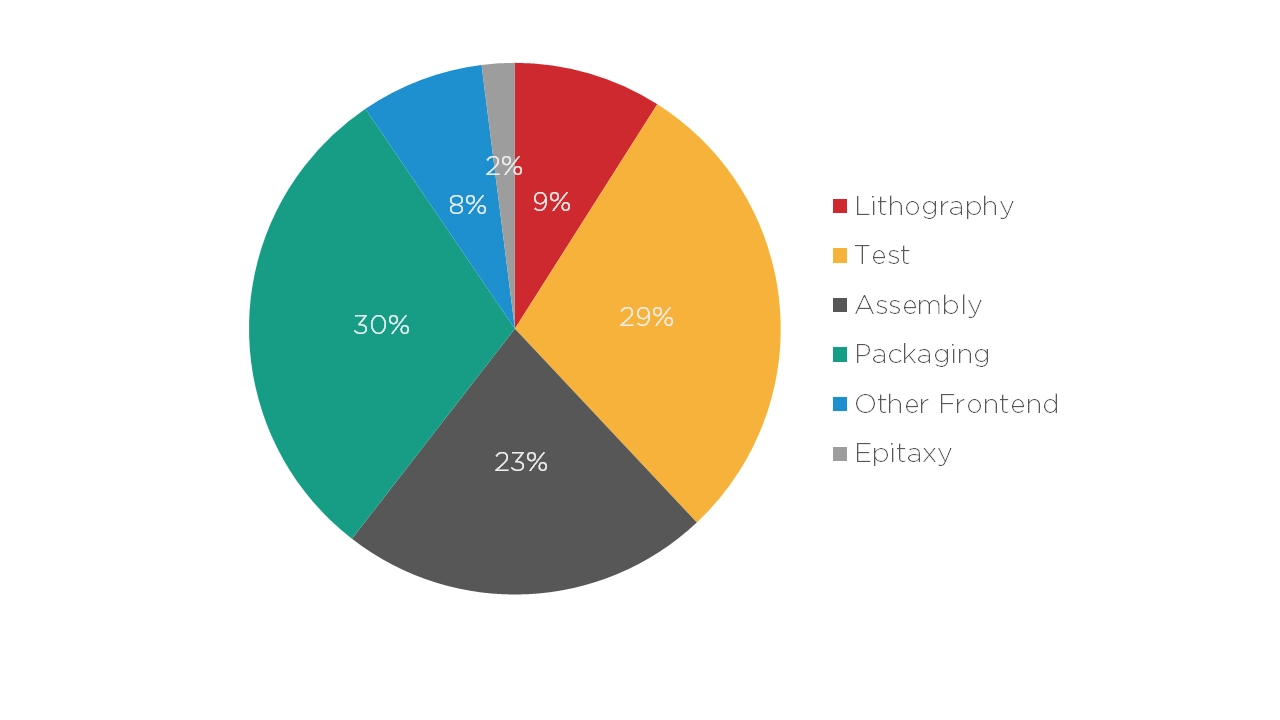

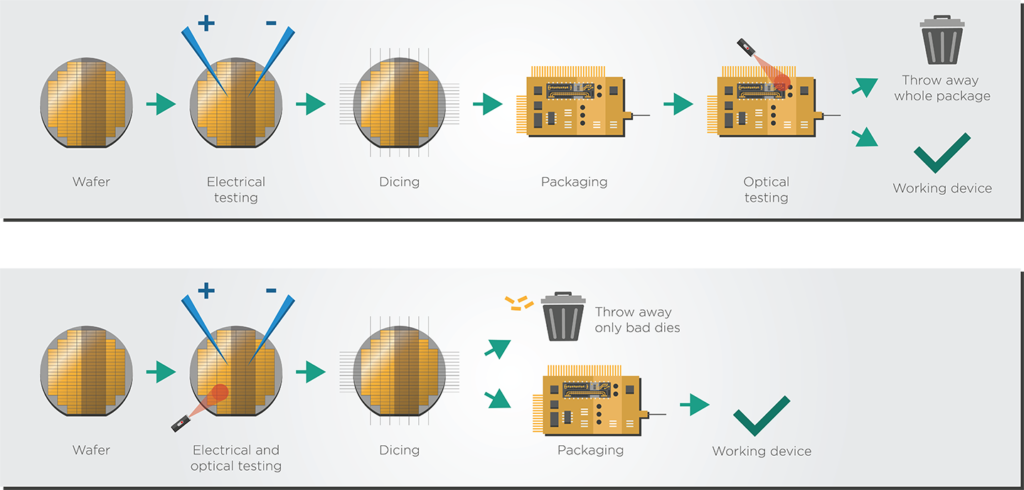

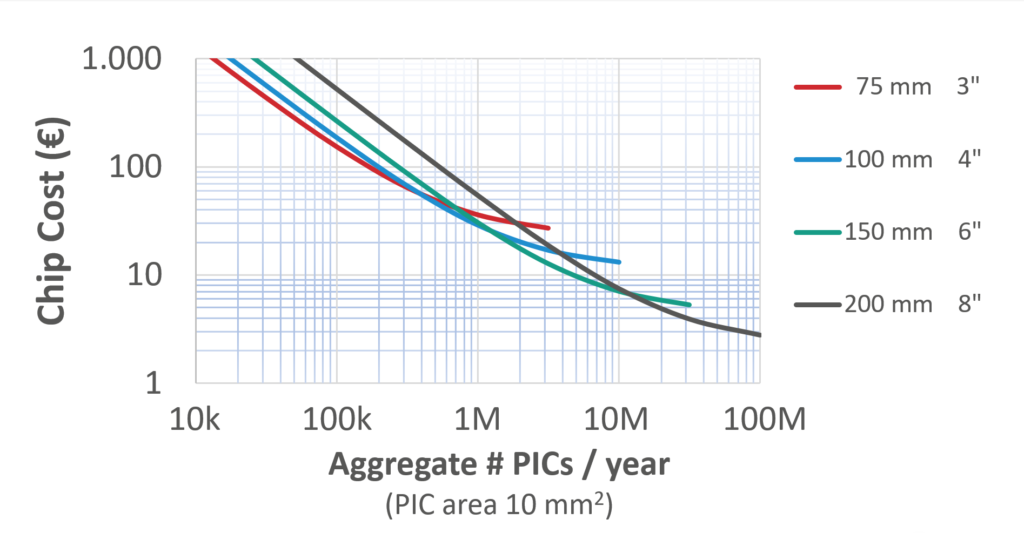

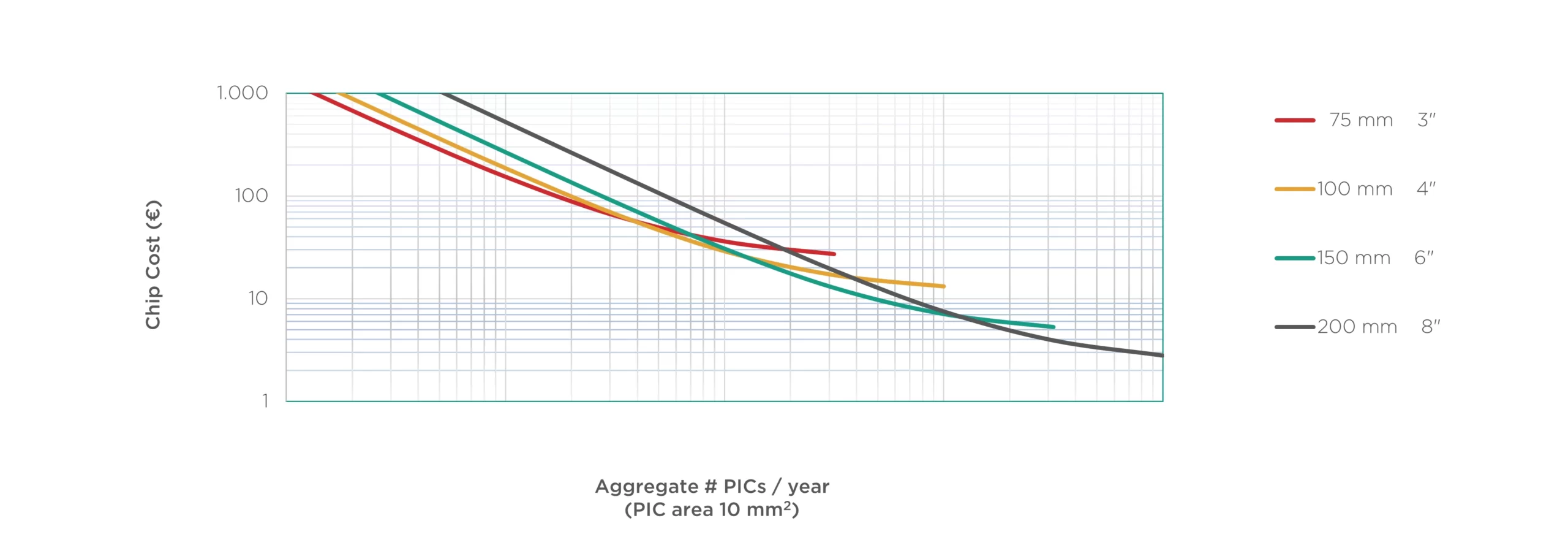

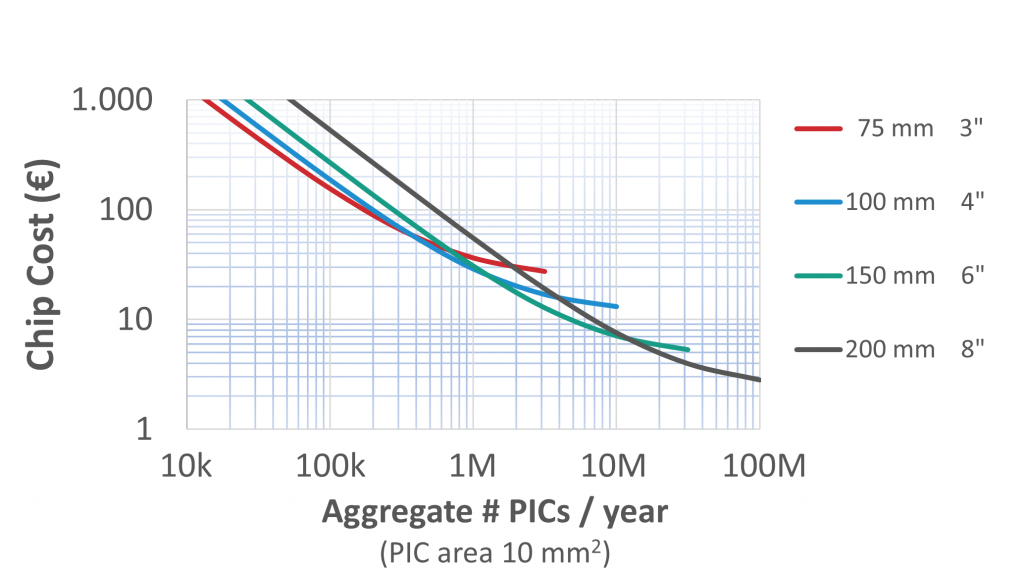

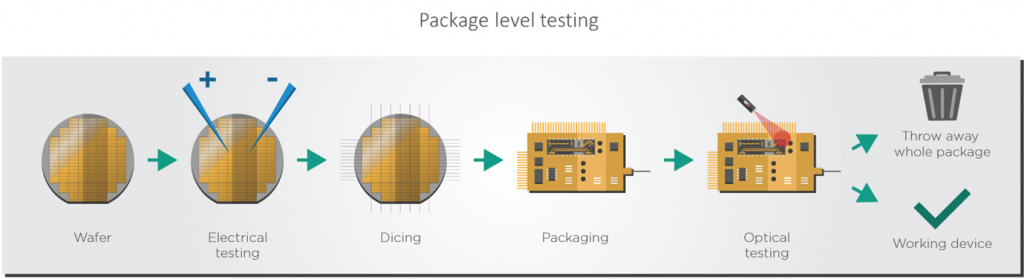

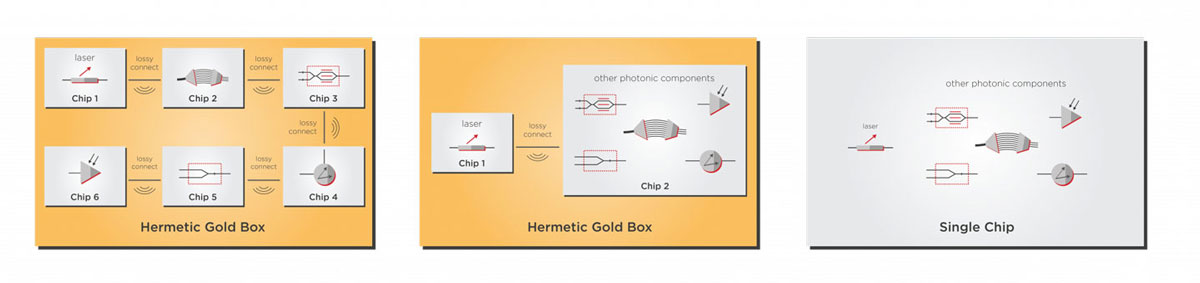

Today, photonics is still a ways off from achieving the goal of becoming more like electronics in its manufacturing process. Photonics manufacturing chains are not at a point where they can quickly produce millions of integrated photonic devices per year. While packaging, assembly, and testing are only a small part of the cost of electronic systems, they are 80% of the total module cost in photonics, as shown in the figure below.

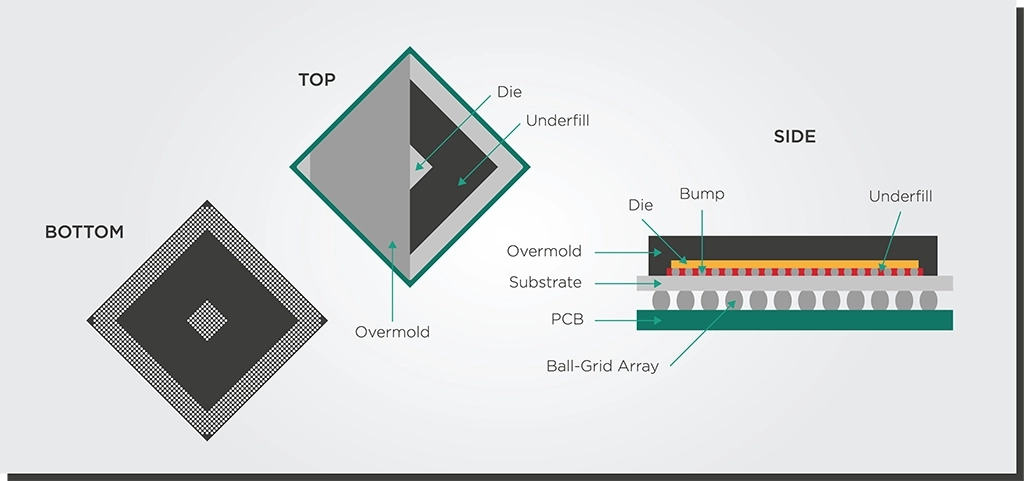

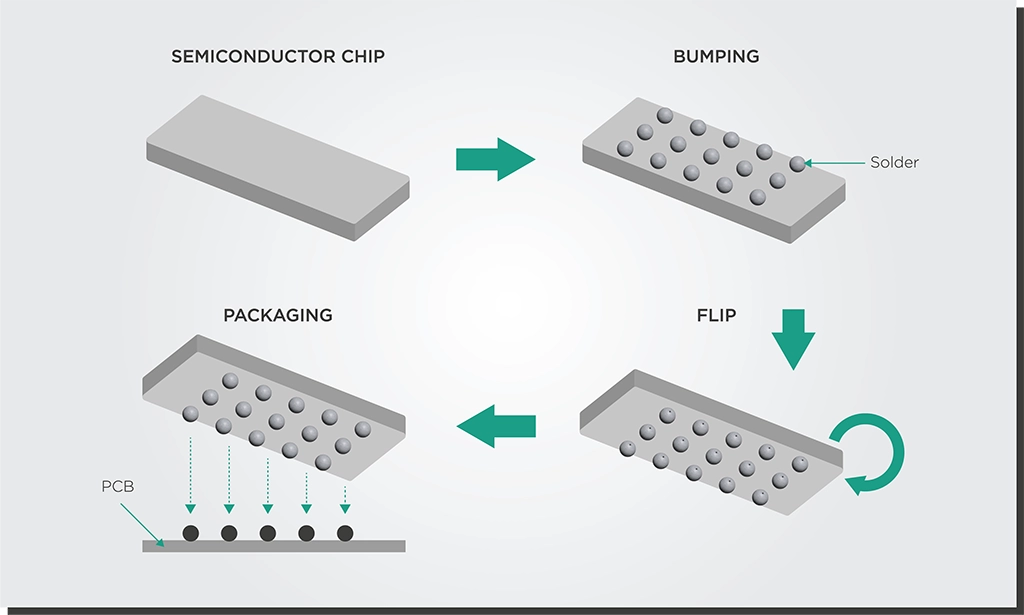

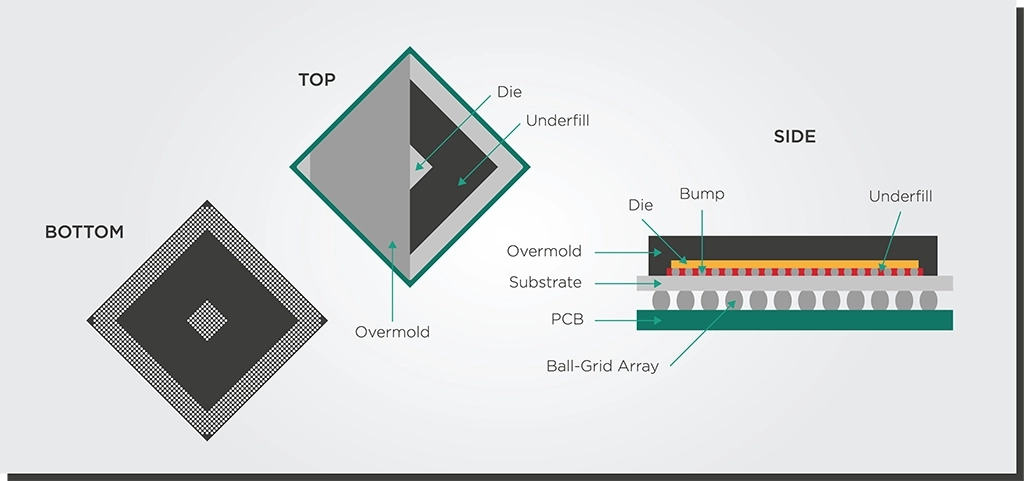

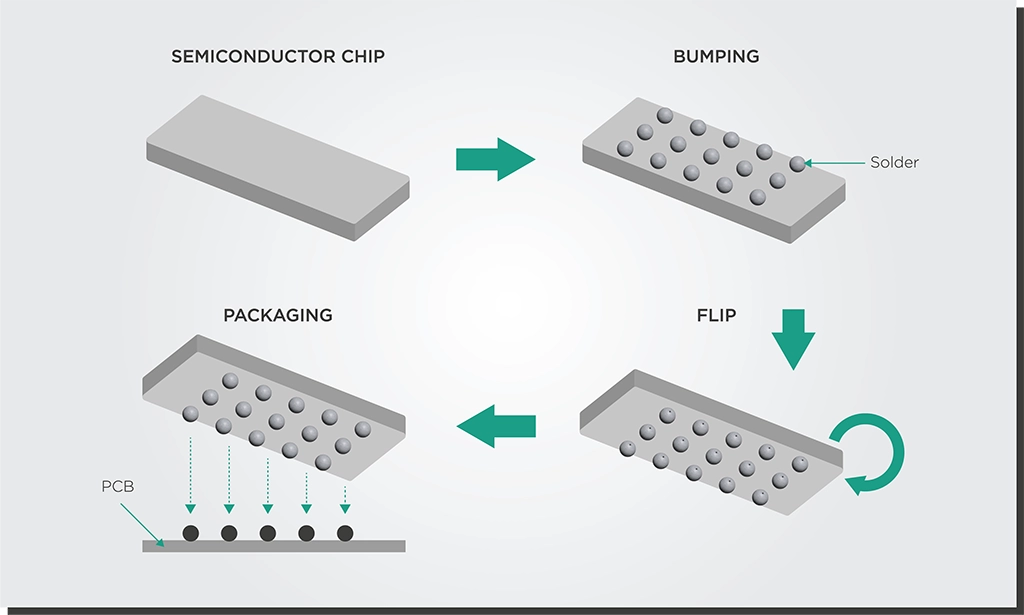

To scale and become more affordable, the photonics manufacturing chains must become more automated and leverage existing electronic packaging, assembly, and testing methods that are already well-known and standardized. Technologies like BGA-style packaging and flip-chip bonding might be novel for photonics developers who started implementing them in the last five or ten years, but electronics embraced these technologies 20 or 30 years ago. Making these techniques more widespread will make a massive difference in photonics’ ability to scale up and become as available as electronics.

The roadmap of scaling integrated photonics and making it more accessible is clear: it must leverage existing electronics manufacturing processes and ecosystems and tap into the same economy-of-scale principles as electronics. Implementing this roadmap, however, requires more investment in photonics. While such high-volume photonics manufacturing demands a higher upfront investment, the resulting high-volume production line will drive down the cost per device and opens them up to a much larger market. That’s the process by which electronics revolutionized the world.

Takeaways

A robust investment is needed to better adapt and integrate microelectronic semiconductor processes into the photonics manufacturing chain to harness the full potential of photonic technologies. Such advancements will not only refine the production scales but also enhance the accessibility and affordability of photonic solutions.

Tags: bandgap, BGA style packaging, Coherent Transceivers, computing power, economy-of-scale principles, EFFECT Photonics, electronic packaging, electronics, Fabless model, Flip-chip bonding, GaAs, high-volume production, III-V semiconductor materials, InP, Investment, lasers, manufacturing chains, microelectronics industry, optical network, Optics, Photodetectors, photonic components, Photonic devices, photonic solutions, Photonics, photonics developers, photonics manufacturing, Semiconductor, semiconductor fabrication techniques, silicon, transistor, wafer-scale technology

The Impact of Photonics on Renewable Energy Systems

The quest for sustainable and clean energy solutions has increasingly turned towards photonics innovations. This…

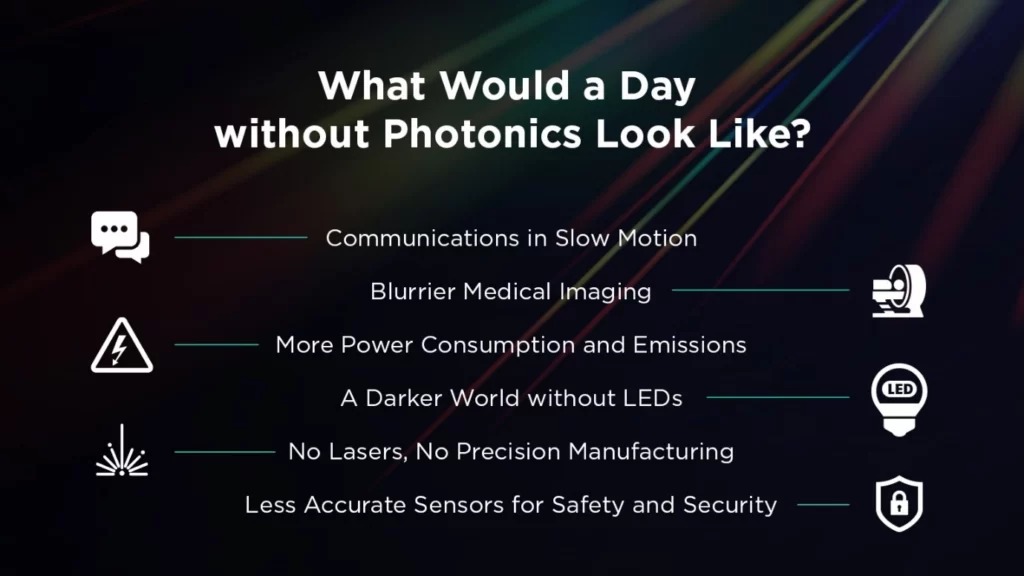

The quest for sustainable and clean energy solutions has increasingly turned towards photonics innovations. This technology, centered around the science and engineering of light, can enhance certain renewable system technologies or enable other infrastructure (such as data centers) to get closer to renewable energy sources.

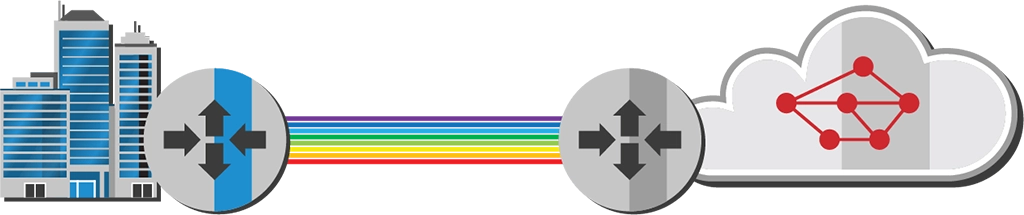

Transfer Data, Not Power

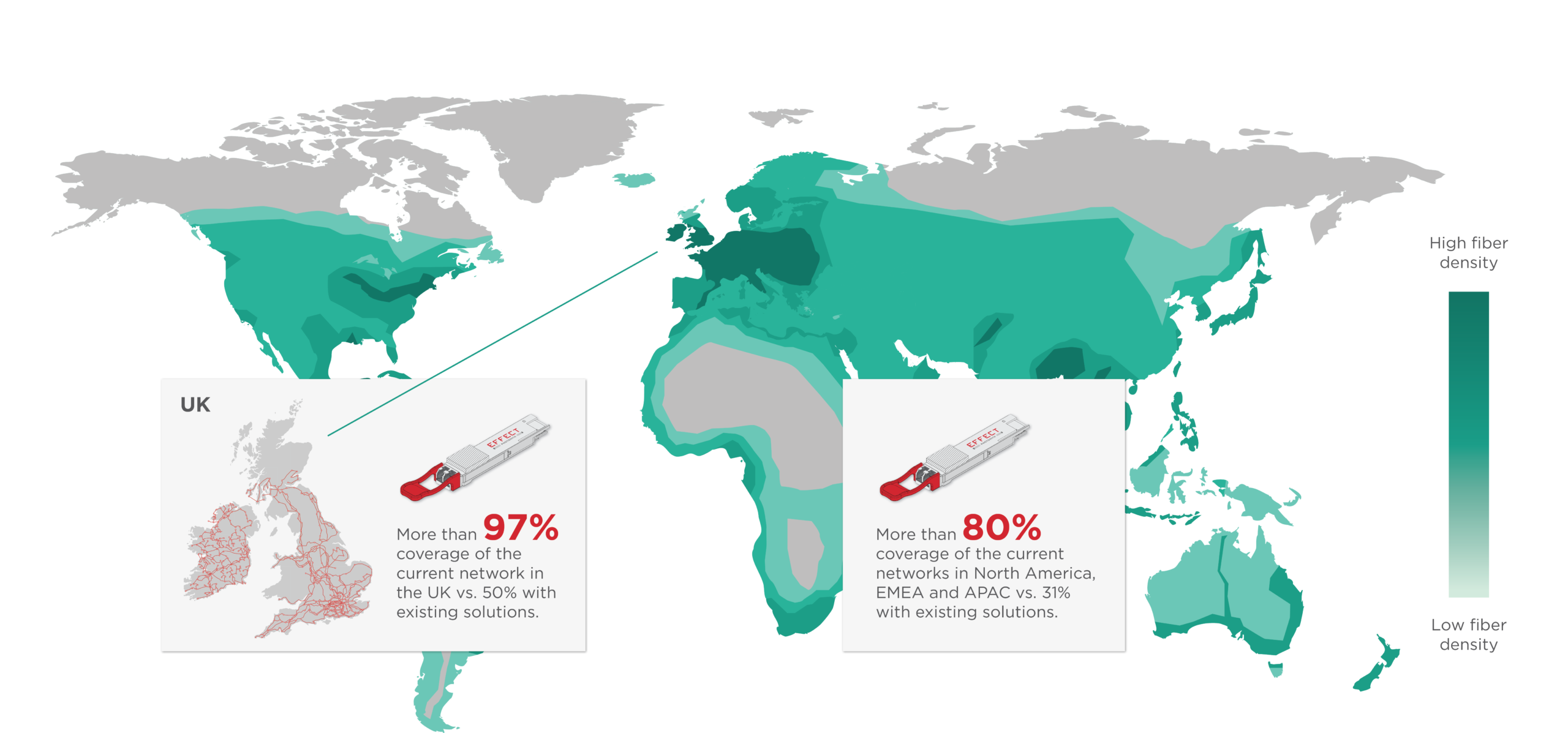

Photonics can play a key role in rethinking the architecture of data centers. Photonics enables a more decentralized system of data centers with branches in different geographical areas connected through high-speed optical fiber links to cope with the strain of data center clusters on power grids.

For example, data centers can relocate to areas with available spare power, preferably from nearby renewable energy sources. Efficiency can increase further by sending data to branches with spare capacity. The Dutch government has already proposed this kind of decentralization as part of its spatial strategy for data centers.

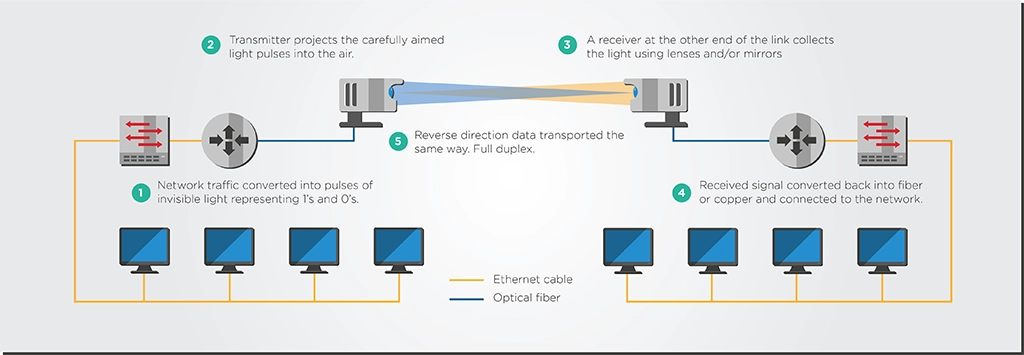

Figure 1: High-speed fiber-optic connections allow data processing and storage to be moved to locations where excess (green) energy is available. Data can be moved elsewhere if power is needed for other purposes, such as charging electric vehicles.

Photonics and Solar Energy

Solar power is gaining popularity as a clean energy source that promises energy independence and environmental benefits while becoming increasingly cost-effective. Although it currently meets only a small portion of global energy needs due to its high costs compared to other technologies, significant advancements have been made thanks to government support and private investment. These developments are steadily positioning solar power as a viable mainstream energy option.

The field of photovoltaics focuses on converting sunlight directly into electricity using materials that exhibit the photovoltaic effect, primarily through solar panels. This field overlaps with the electronics semiconductor industry as both utilize similar materials, such as silicon, and share similar manufacturing techniques.

Photonics and photovoltaics are closely related because they use techniques to manipulate light. Therefore, some techniques (such as optical waveguides on semiconductors) used for photonic communication systems could also be useful to the photovoltaic sector. Meanwhile, advances in photonic communications, such as developing new materials that interact efficiently with light, can directly enhance the efficiency and effectiveness of photovoltaic cells, which capture solar energy. For example, developing photonic crystals and other nanostructured materials can lead to solar panels that trap sunlight more effectively.

There are other creative ways to use photonics technology here. For example, Ambient Photonics is a startup that develops low-light solar cells designed to generate power efficiently under indoor lighting conditions. Their technology focuses on providing a clean, sustainable energy source for powering Internet of Things (IoT) devices and other electronics that traditionally rely on batteries. By using their photovoltaic cells, Ambient aims to reduce dependency on traditional battery power and enhance the sustainability of devices through renewable energy integration.

The Impact on Wind Energy Monitoring

PhotonFirst, a Dutch startup, develops advanced photonic sensors specifically designed to enhance the efficiency and maintenance of wind turbines. Their sensors use light to measure critical turbine parameters in real-time, informing turbine operators about the behavior of components such as blades, towers, gearboxes, and cabling. This precise data helps optimize turbine performance, predict maintenance needs, and reduce downtime, thereby improving energy output and extending the lifespan of the turbines.

Initially, fiber optic sensing in wind turbines was only used at the blade roots to monitor load and temperature, and expanding this technology throughout large turbines was costly. However, PhotonFirst is trying to broaden the applications of such sensor systems while also enhancing their performance at a more manageable cost.

Takeaways

The synergy between photonics and renewable energy can lead to some important advances in the pursuit of sustainable power. Through advancements in solar energy conversion, wind energy monitoring, and moving data centers closer to renewable energy sources, photonics can help change how we generate, distribute, and utilize energy.

Tags: advances, Ambient Photonics, clean energy, data centers, Decentralization, EFFECT Photonics, electricity, energy output, engineering, high-speed optical fiber, infrastructure, innovations, Internet of Things (IoT) devices, lifespan, light, low-light solar cells, maintenance, manufacturing techniques, materials, nanostructured materials, optimization, photonic communication systems, photonic crystals, Photonic Sensors, Photonics, photovoltaics, power grids, real-time data, renewable energy, renewable system technologies, science, Semiconductor Industry, solar panels, Solar power, spatial strategy, Sustainable, sustainable power, synergy, technology, turbine parameters, wind energy monitoring

The Evolution of Data Center Interconnects

The digital era’s rapid expansion requires advances in data center interconnects (DCIs) to support the…

The digital era’s rapid expansion requires advances in data center interconnects (DCIs) to support the burgeoning demands of cloud computing and data architecture.

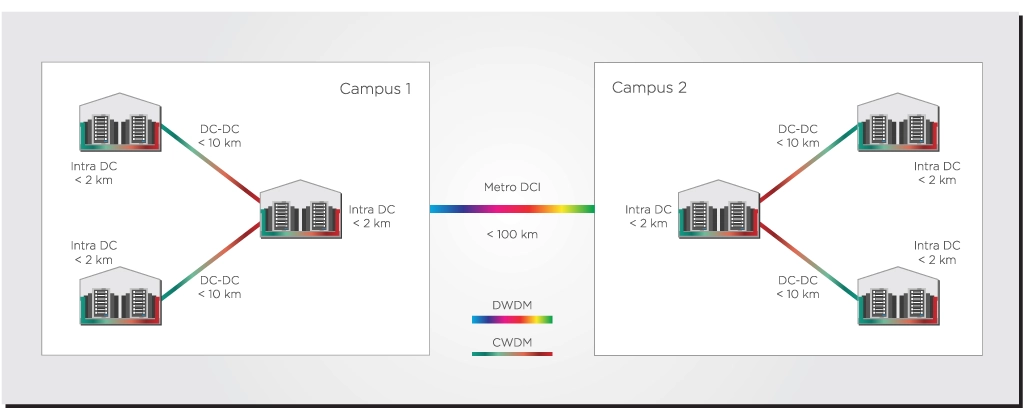

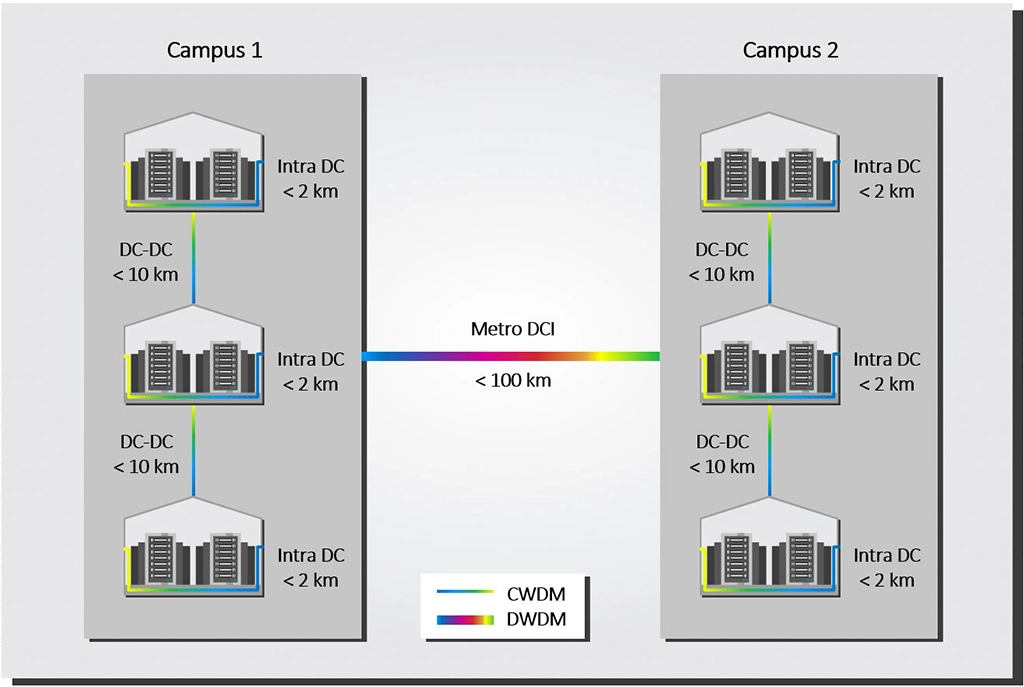

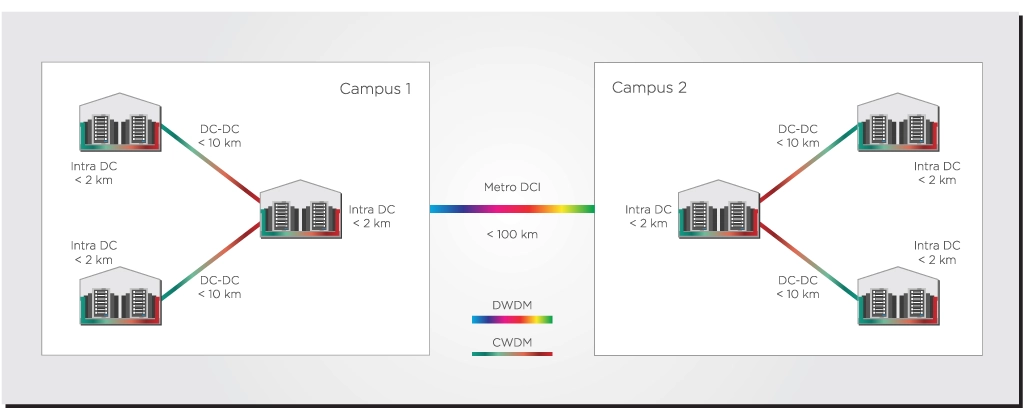

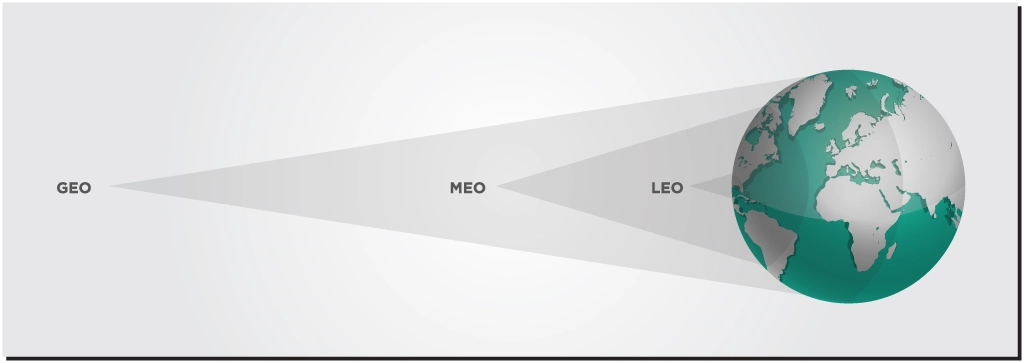

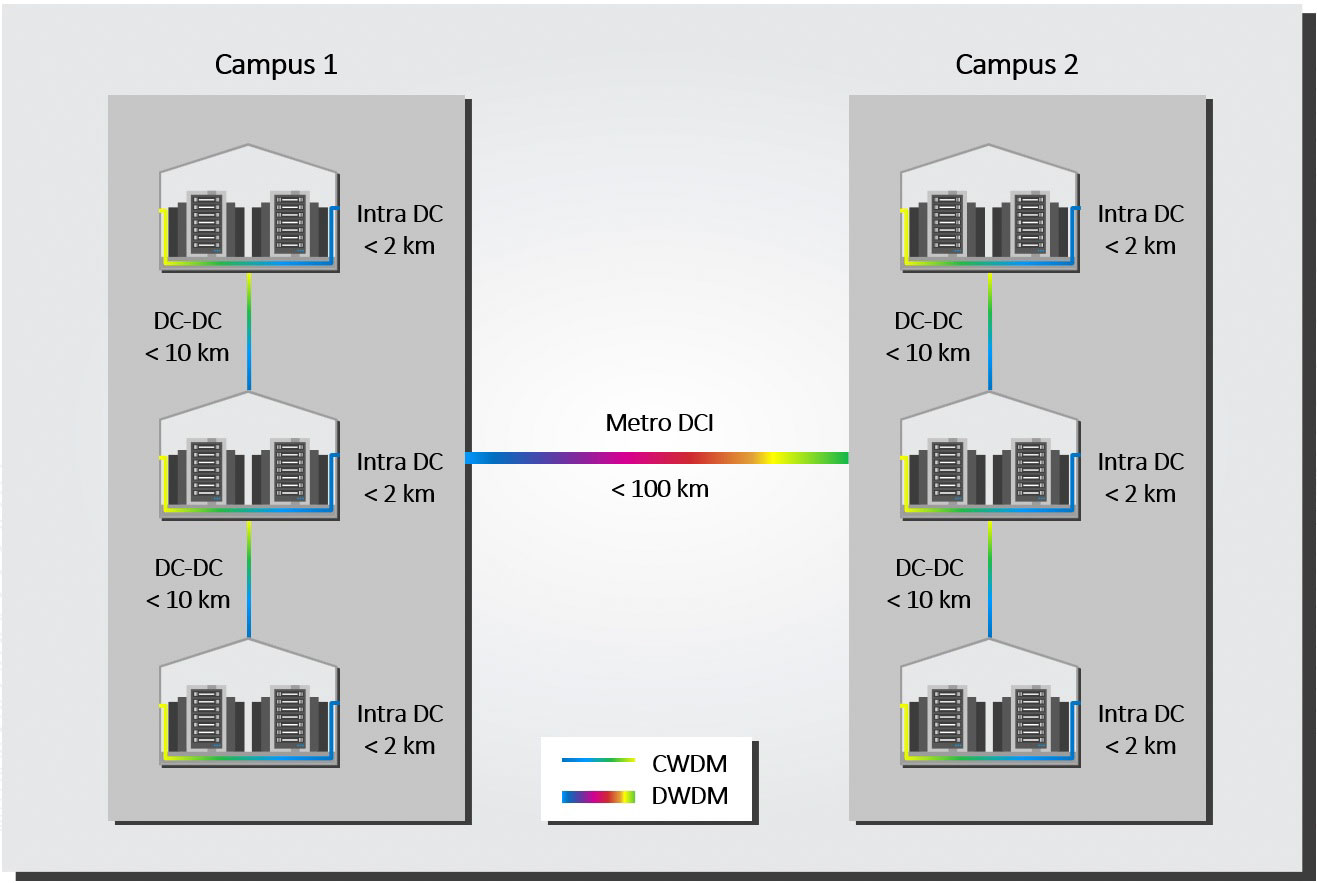

For the sake of this article, let’s think broadly about three categories of data center interconnects based on their reach and location with relation to the data center

- Intra-data center interconnects (< 2km)

- Campus data center interconnects (<10km)

- Metro data center interconnects (<100km)

As data centers become more complex and AI increases its demands on them, the intra-data center sector is increasing in complexity and variety, but that will be the subject of a different article.

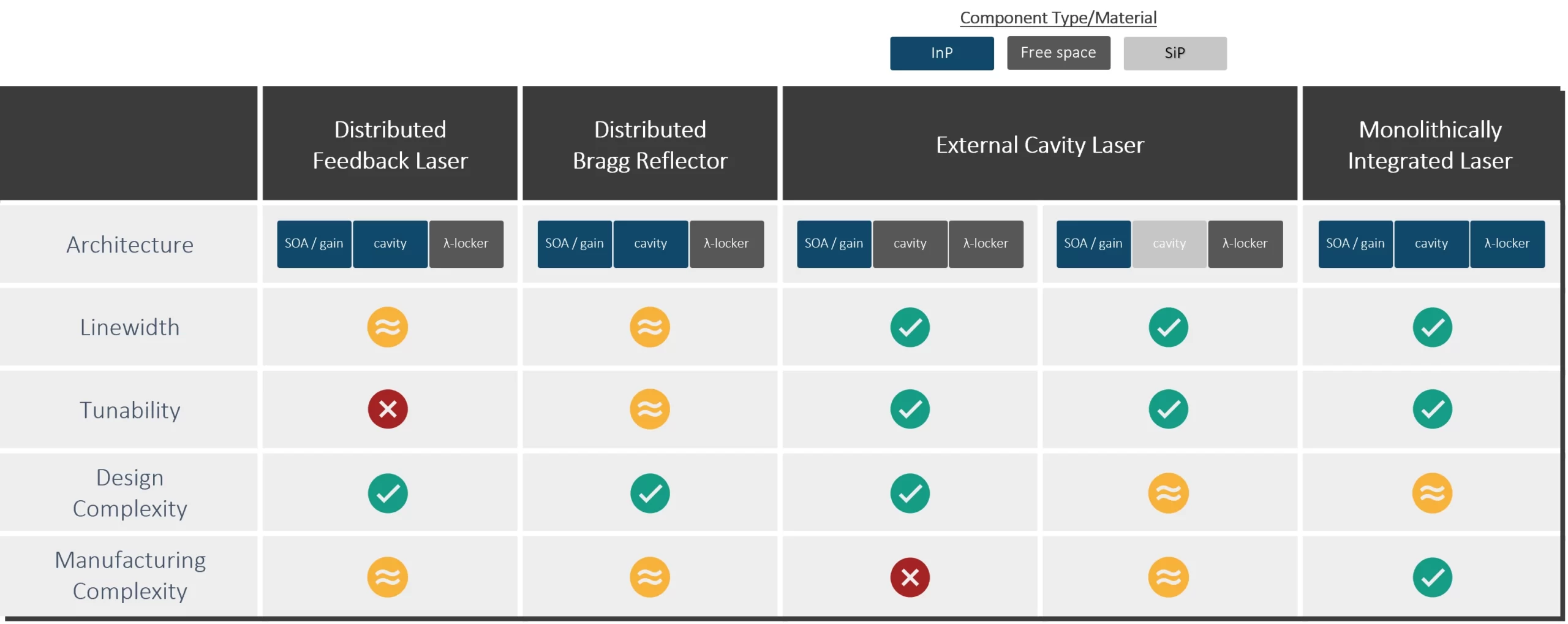

Coherent optical technology has established itself as the go-to solution for interconnecting data centers over longer distances, while direct detect continues to dominate the intra data center sector.

The Increasing Importance of Decentralizing Data Centers

Smaller data centers placed locally have the potential to minimize latency, overcome inconsistent connections, and store and compute data closer to the end-user. These benefits are causing the global market for edge data centers to explode, with PWC predicting that it will nearly triple from $4 billion in 2017 to $13.5 billion in 2024.

Meanwhile, the demands of new AI infrastructure are pushing data center power consumption to such a degree that the electrical power grid might be unable to sustain it. Longer data center interconnects enable a more decentralized system of data centers with branches in different geographical areas connected through high-speed optical fiber links to cope with the strain of data center clusters on power grids.

These trends push the data center industry to look for interoperable solutions for longer interconnects over distances of 80 to 120 km. The advances in electronic and photonic integration allowed coherent technology for metro DCIs to be miniaturized into QSFP-DD and OSFP form factors. This progress allowed the Optical Internetworking Forum (OIF) to create the 400ZR and ZR+ standards for 400G DWDM pluggable modules. With small enough modules to pack a router faceplate densely, the datacom sector could profit from a 400ZR solution for high-capacity data center interconnects of up to 80km.

After the success of 400ZR standardization, the data center industry and the OIF are starting to promote an 800ZR standard to enable the next generation of interconnects. In OFC 2024, we started seeing some demos from several vendors and the OIF on this new standards initiative.

Direct Detect and Coherent Technology in DCIs

For many years, there has been an expectation that the increasing capacity demands on data centers would reach a point where coherent technology would deliver a lower cost per bit and power per bit than direct detect technologies.

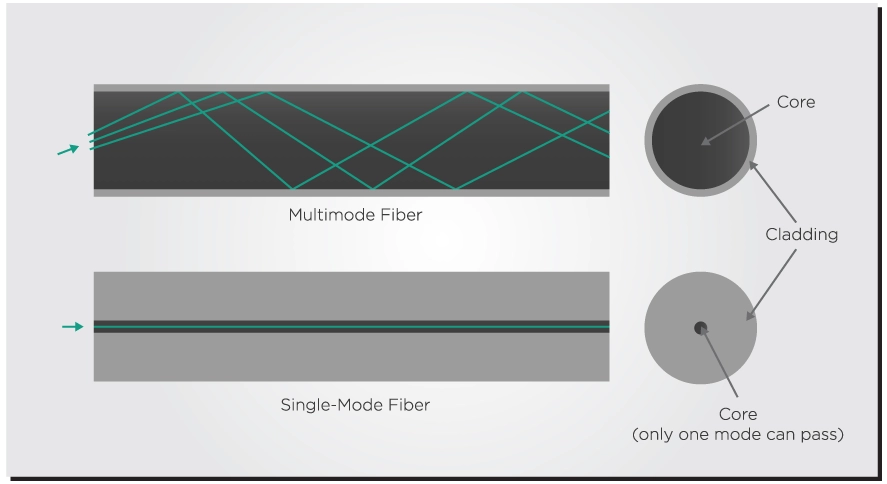

However, direct detect technology (both NRZ and PAM-4) continues to successfully overcome the challenges of coherent technology and will continue to dominate the intra-DCI space (also called data center fabric) in the coming years. In this space, links span less than two kilometers, and for particularly short links (< 300 meters), affordable multimode fiber (MMF) is frequently used.

The tendency towards data center decentralization will also impact the inside of data centers. Larger data centers can require longer interconnects from one building to another. So in a way, some links inside the data centers could become more like campus DCI links, which require single-mode fiber solutions, and in those spaces coherent might have a better chance of becoming competitive.

Takeaways

The decision to use coherent or direct detection technology for DCIs boils down to the reach and capacity needs. Coherent is already established as the solution for metro DCIs, and efforts are underway towards an 800ZR standard to follow up on the highly successful 400ZR interconnect standard. With the move to Terabit speeds and scaling production volumes, it was expected to become competitive in the data center sector, too, but for now, direct detect technology continues to dominate this sector.

From basic networking to sophisticated, AI-enhanced architectures, DCIs have become the backbone of the digital infrastructure, enabling the seamless operation of global cloud services and data centers.

Tags: 400ZR, 800ZR, AI, Campus interconnects, cloud computing, coherent optical technology, data architecture, Data center interconnects, DCIs, decentralizing data centers, digital era, Direct Detect, edge data centers, EFFECTPhotonics, electrical power grid, global cloud services, intra-data center, metro DCIs, multimode fiber, NRZ, OFC 2024, PAM-4, photonic integration, power consumption, single-mode fiber, Terabit speeds

Coherent Optics Explained

In the always-evolving world of communications, coherent optics deeply improved our ability to transmit at…

In the always-evolving world of communications, coherent optics deeply improved our ability to transmit at high capacity over vast distances. Coherent optical fiber communications were studied extensively in the 1980s to improve optical transmission reach, but the high complexity of receivers made the technology not so cost-effective to deploy. After 2005, a technological breakthrough made coherent systems more economically viable, and ever since, they’ve become a big part of optical networks. Since then, coherent technology has slowly but surely spread out from the network core and become more widely available on the network edge, which is a transition that EFFECT Photonics believes in.

This article delves into the fundamental principles behind coherent optics and why it’s become indispensable in modern telecommunications infrastructure.

The Basics of Coherent Transmission

Let’s start by discussing some basic concepts.

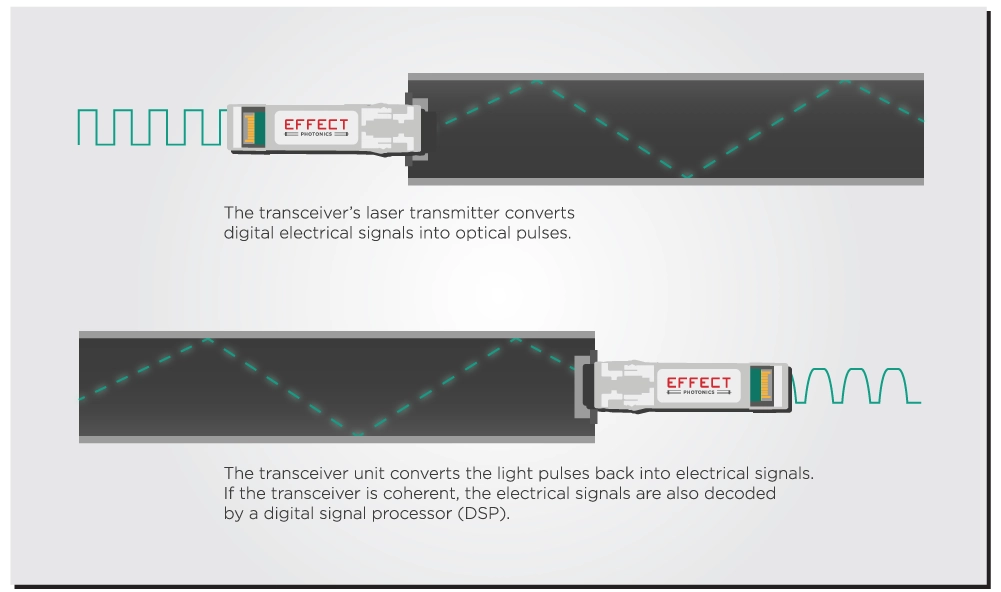

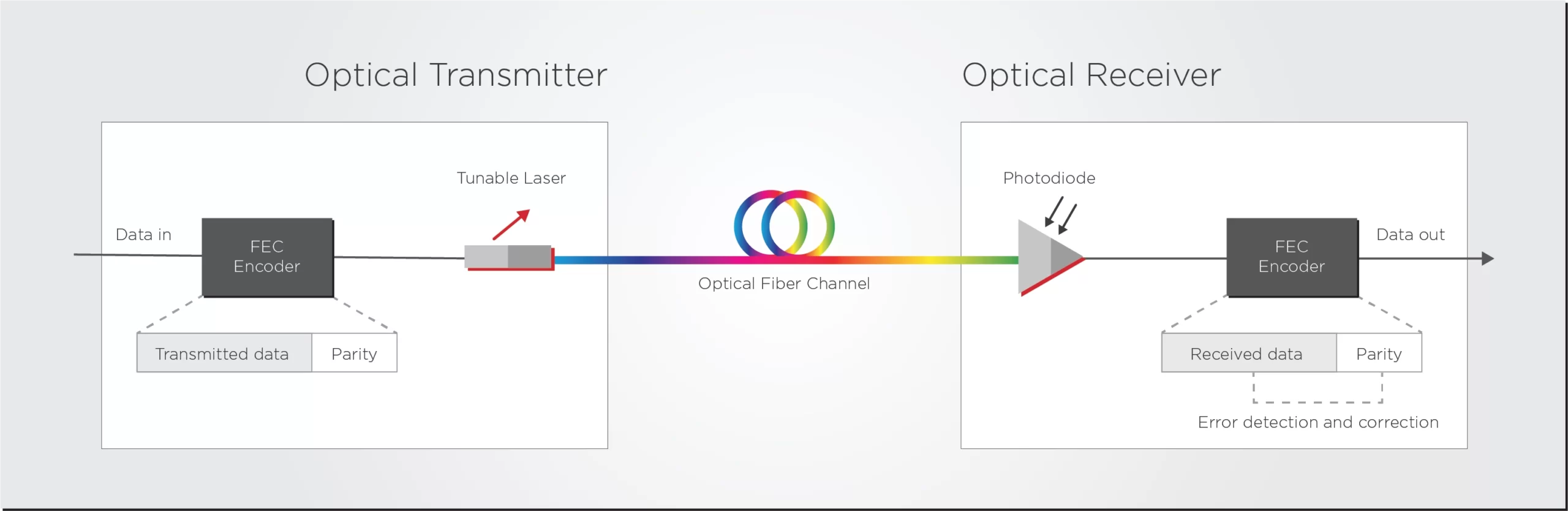

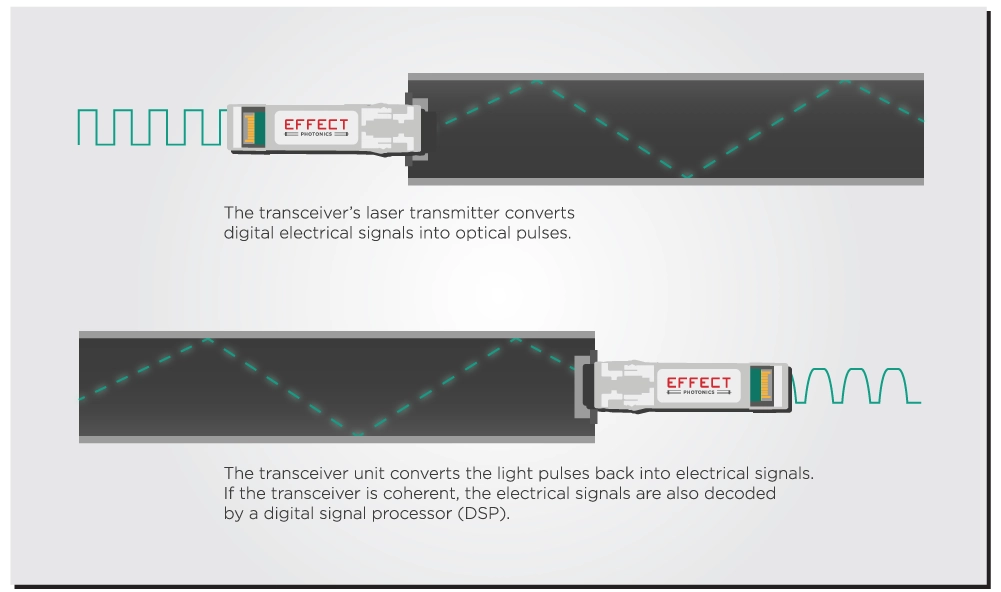

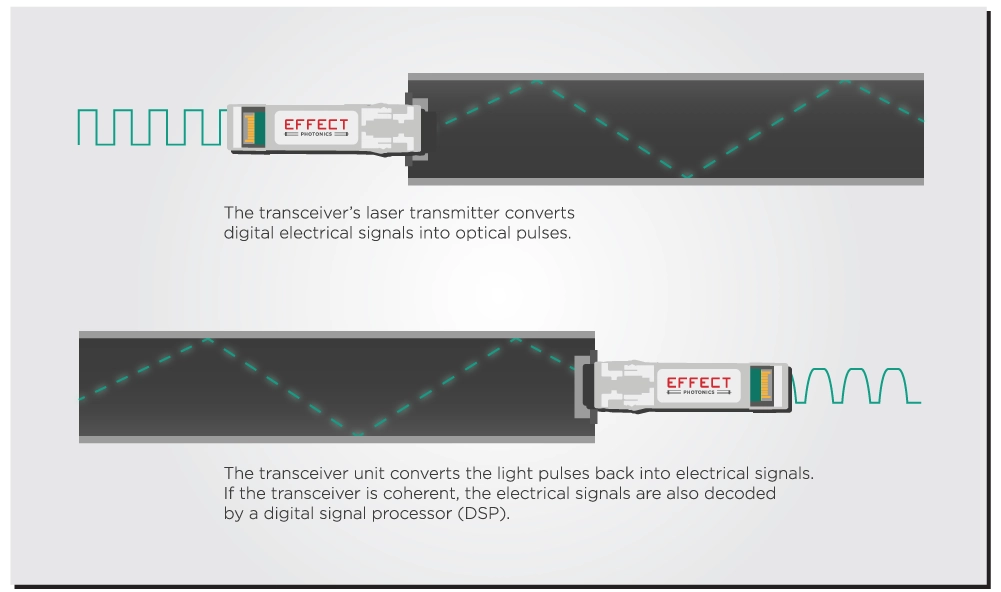

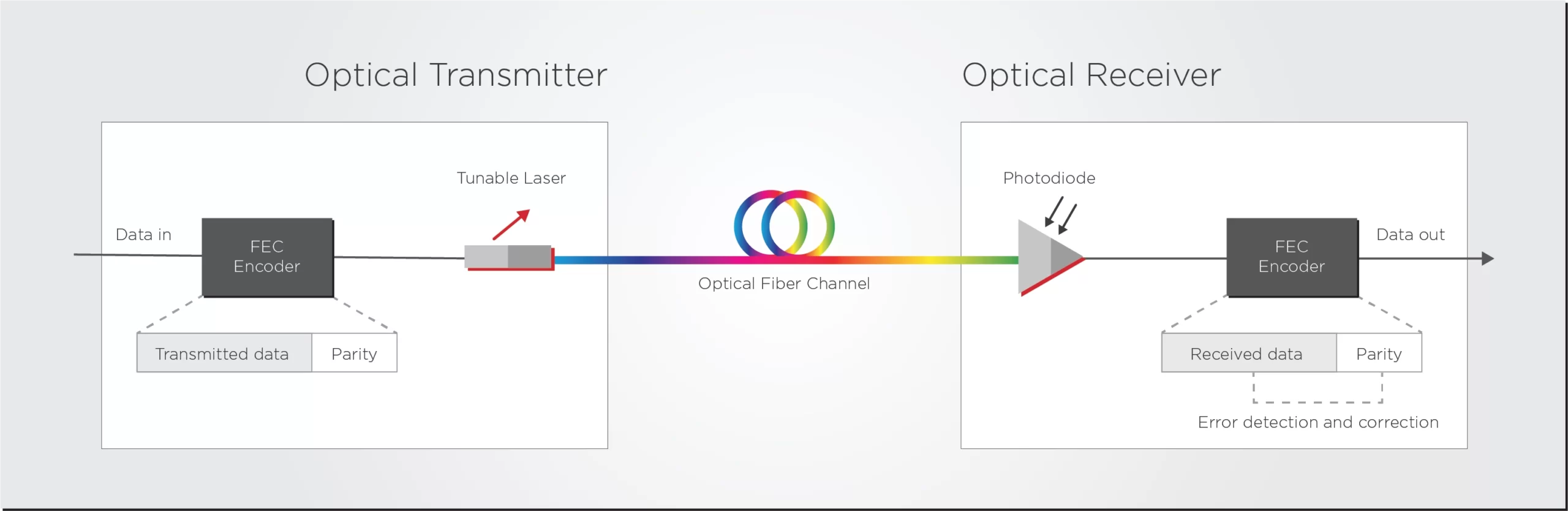

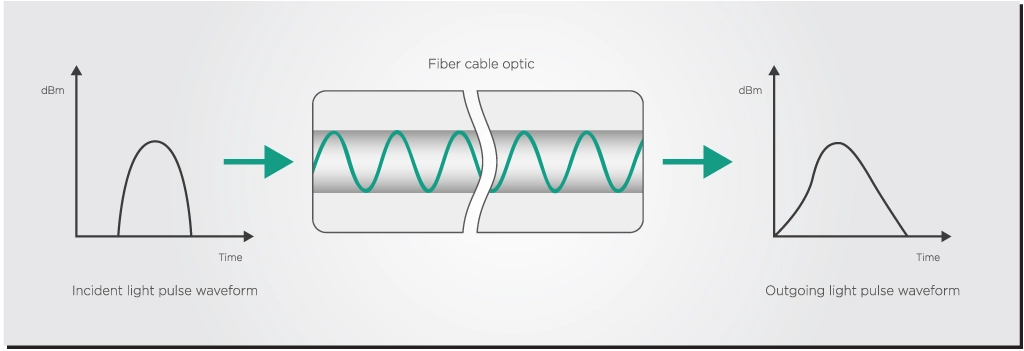

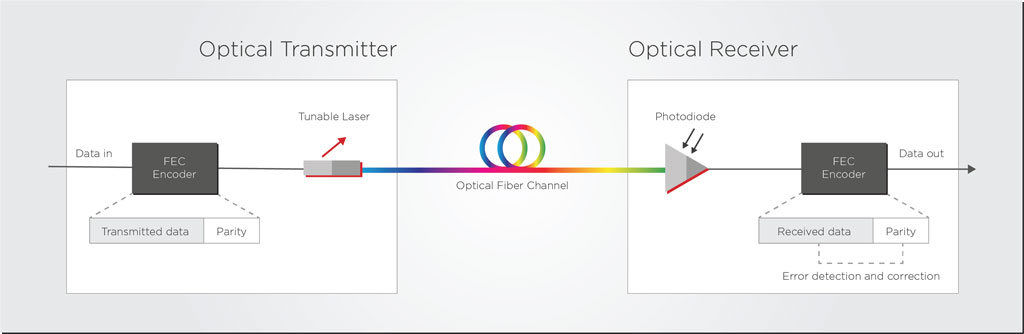

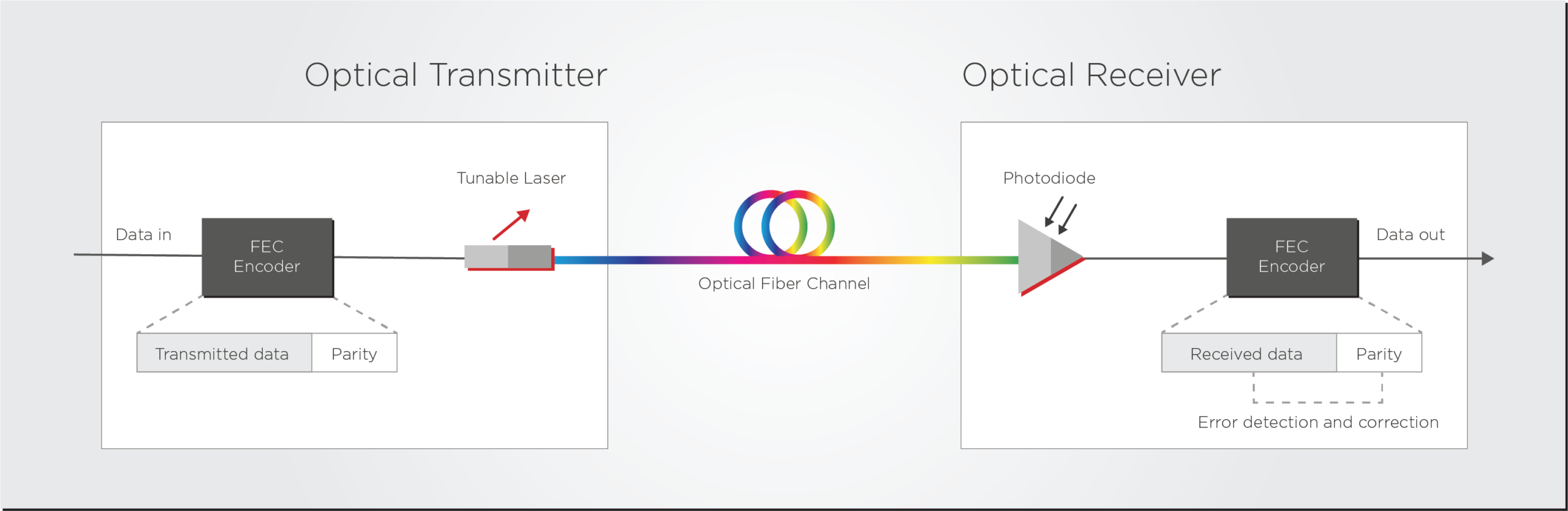

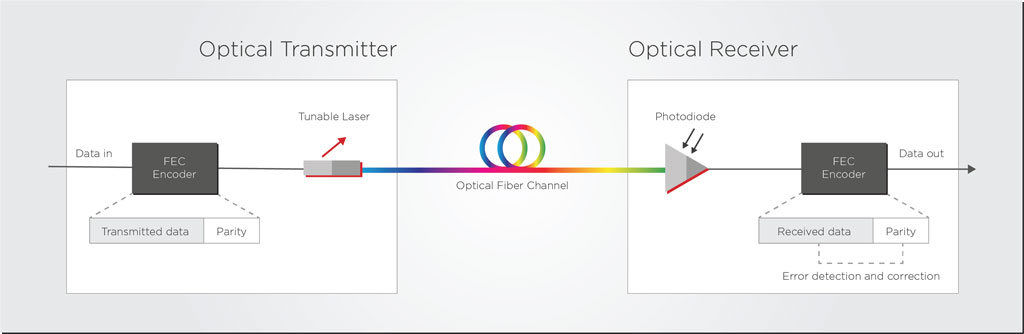

An optical transceiver is a device that converts electrical signals into optical signals for fiber transmission and vice versa when the optical signal is received. It interfaces between fiber optical networks and electronic computing devices such as computers, routers, and switches.

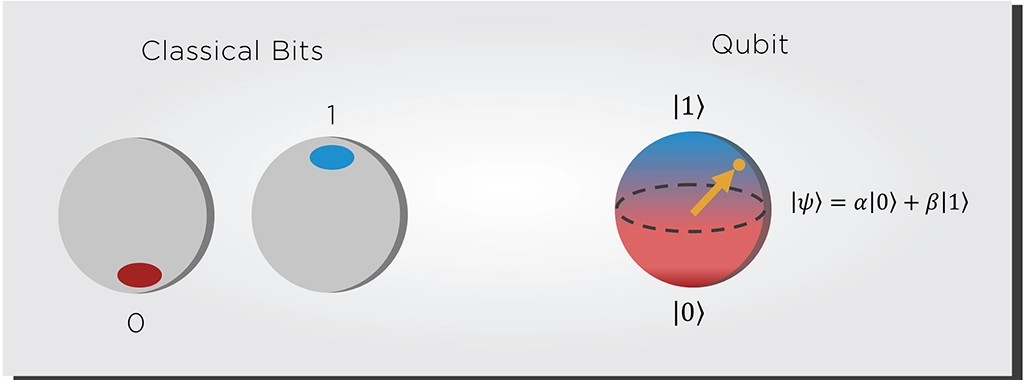

There are a few ways to encode electrical data into light pulses. Perhaps the most basic way is called intensity modulation/direct detection (IM-DD). That’s a fancy way of saying that the same digital 0s and 1s of your electrical signal will be imposed directly on your light signal. This method is akin to turning a flashlight on and off to send a Morse code message.

The advantage of IM-DD transmission is that its simplicity makes the transceiver design simpler and more affordable. However, there are limitations to how much data and distance this approach can cover.

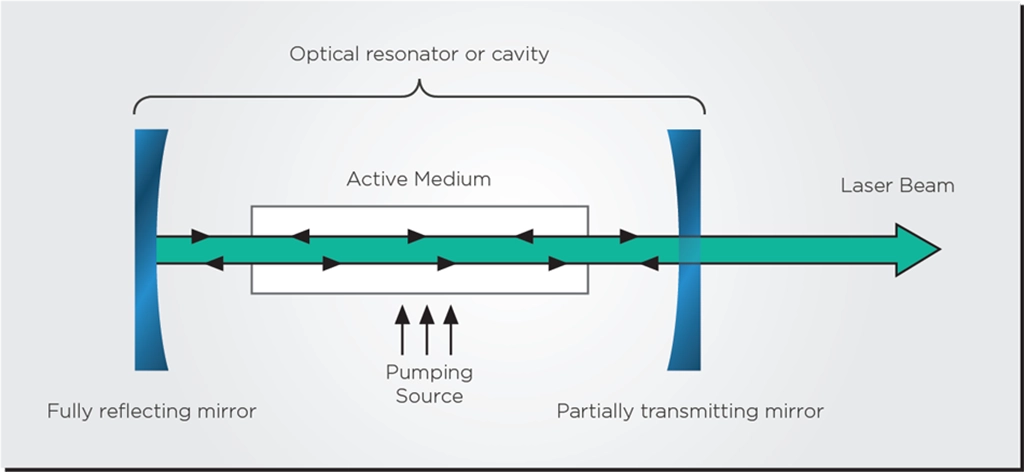

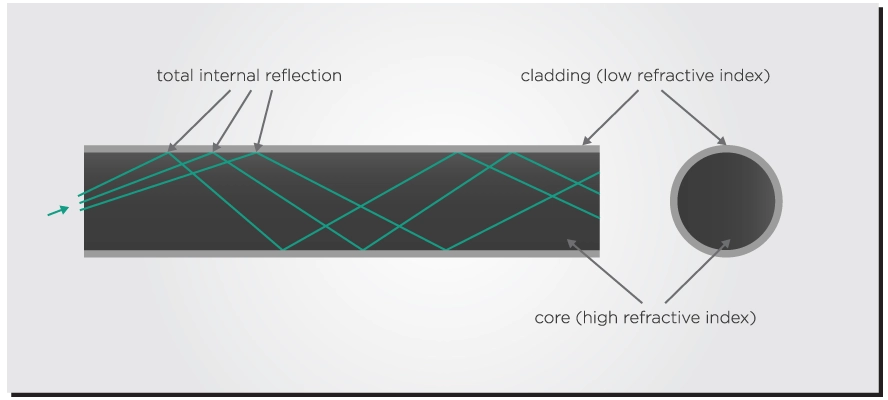

Coherent transmission improves the range and capacity of data transmission by encoding information in other properties of a light wave. To summarize the key light properties:

- the intensity is essentially the height of the light wave

- the phase is the position of the wave in its cycle

- the polarization is the orientation of the wave

While IM-DD transmission only encodes information in the intensity of a light wave, coherent transmission encodes information into all three properties, allowing coherent systems to send far more data bits in a single light wave. A receiver’s ability to read the phase and polarization also makes the optical signal more tolerant to noise, which expands the potential transmission distance. The following video from our YouTube channel explains briefly how this works in a more graphical way.

The Role of a DSP and Laser in Coherent Systems

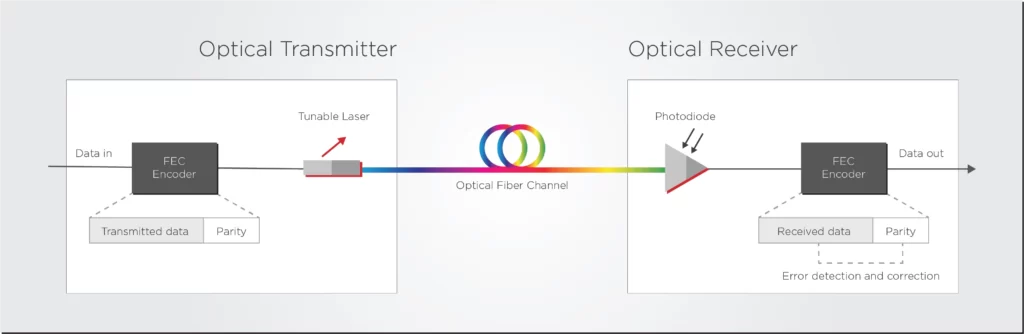

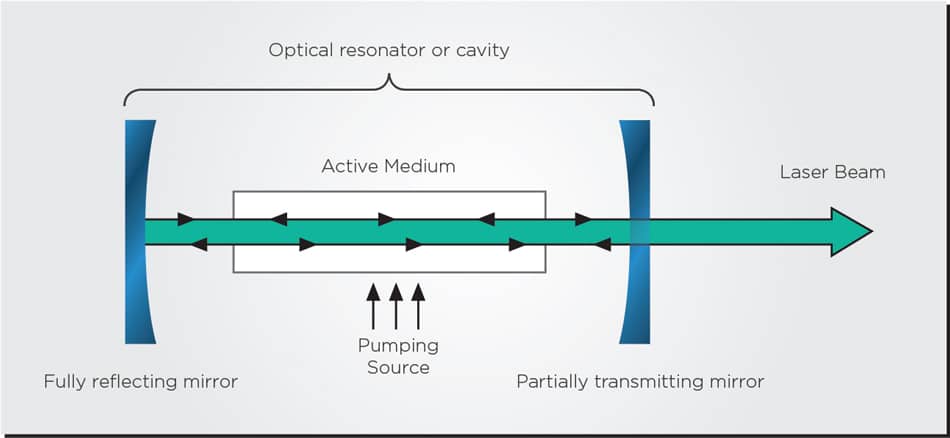

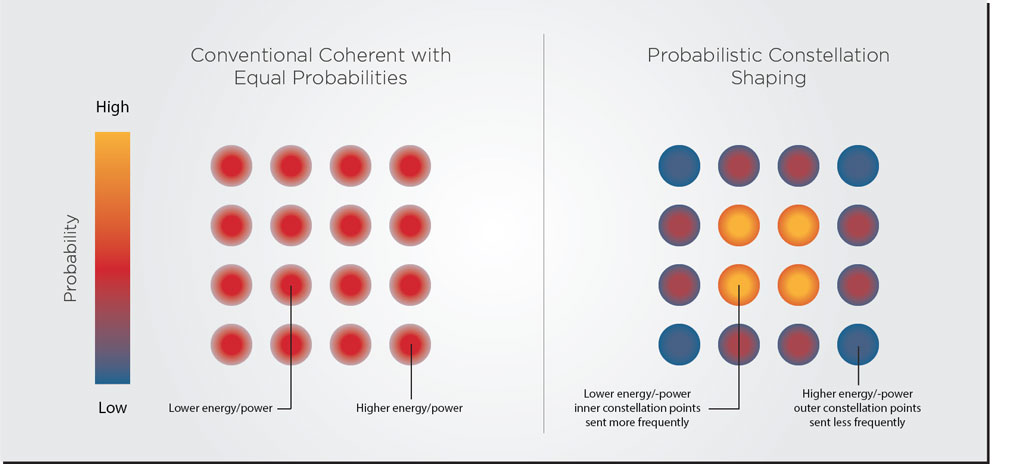

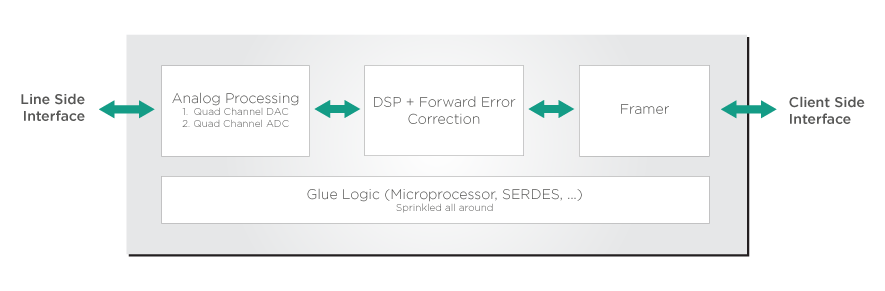

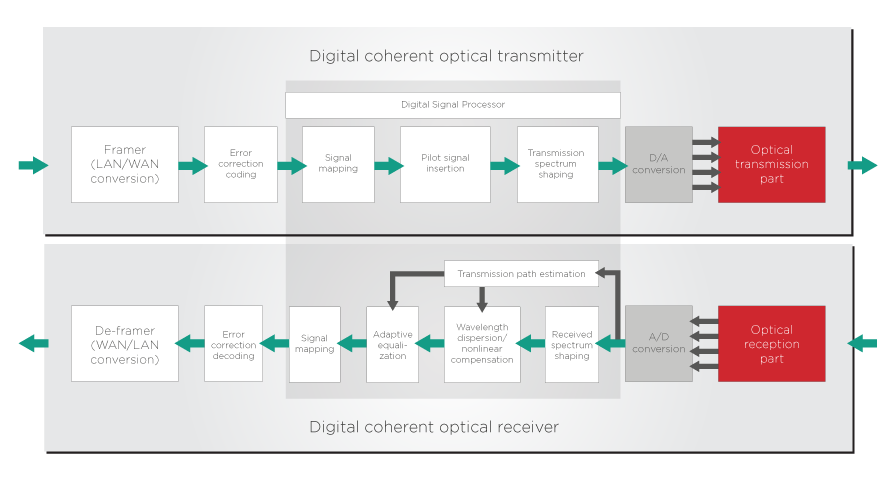

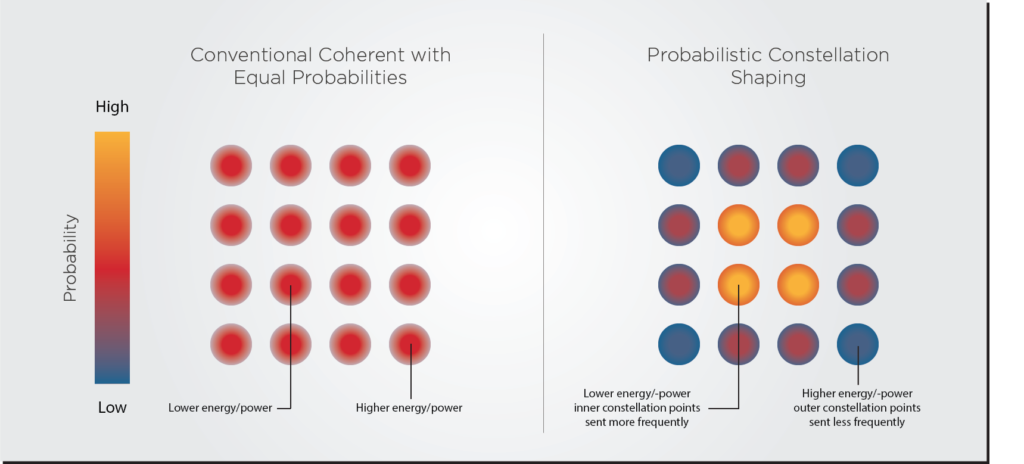

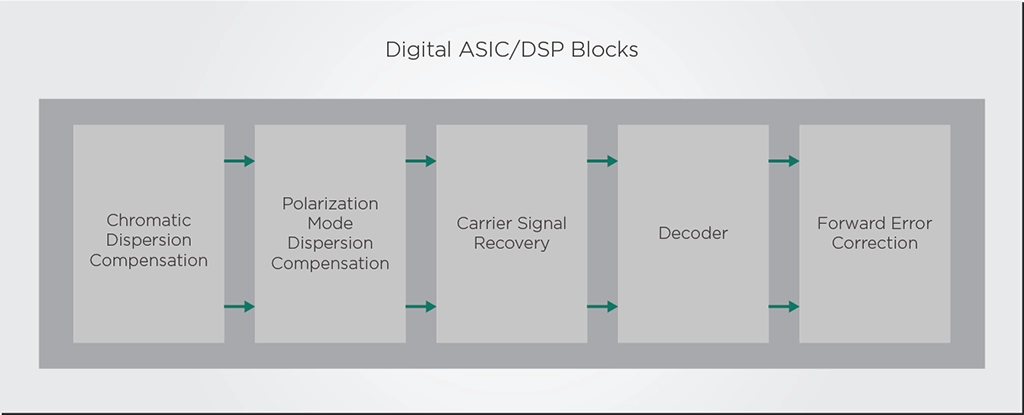

A sophisticated digital signal processor (DSP) encodes and decodes electrical signals into light signals in a coherent system. This is the electronic heart of the system. The DSP does much more than that: it compensates for transmission impairments in the fiber, performs analog-to-digital signal conversions (and vice versa), corrects errors, encrypts data, and monitors performance. Recently, DSPs have taken on more advanced functions, such as probabilistic constellation shaping or dynamic bandwidth allocation, which enable improved reach and performance.

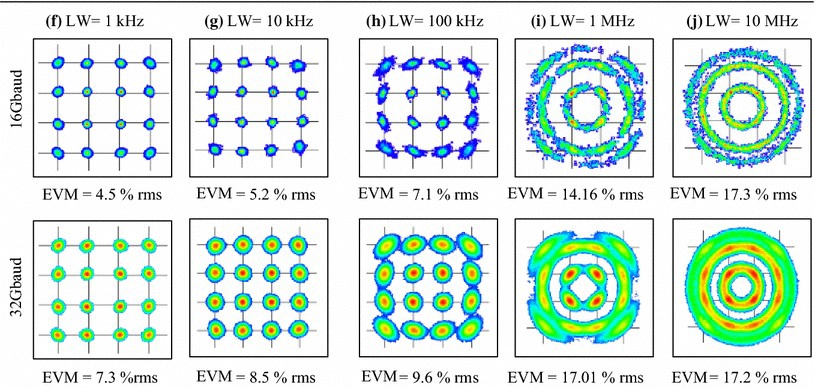

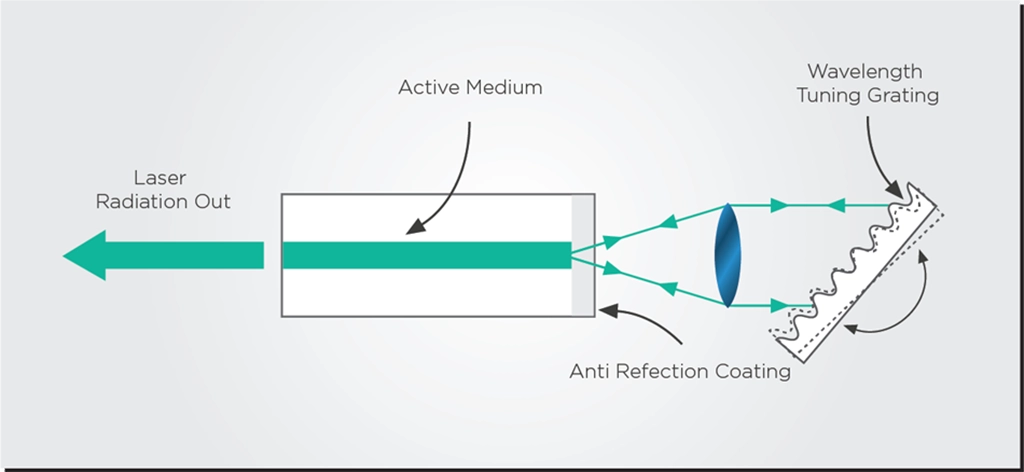

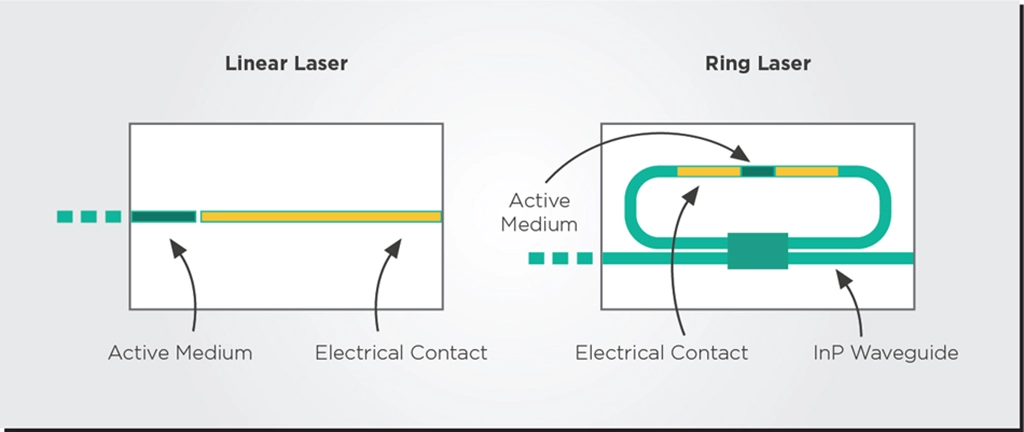

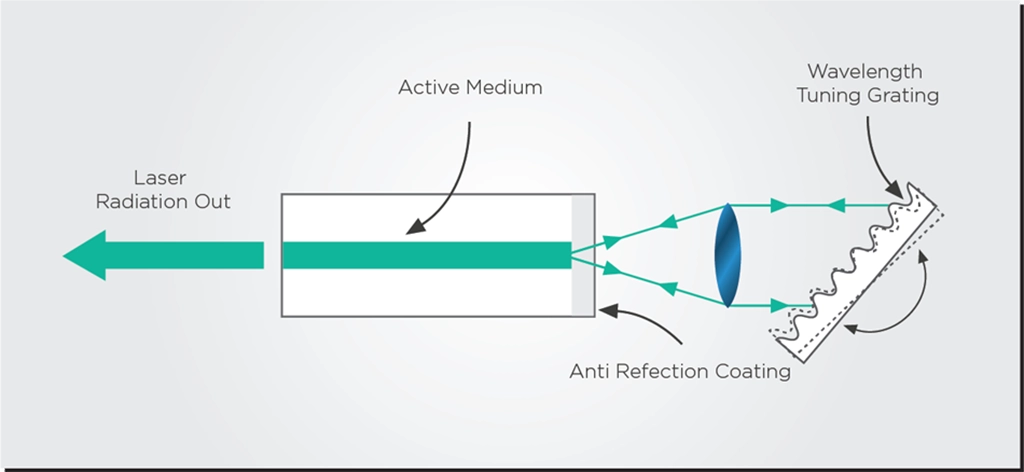

The tunable laser is also a core component of all these optical communication systems, both IM-DD and coherent. The laser generates the optical signal encoded and sent over the optical fiber. Thus, the purity and strength of this signal will massively impact the bandwidth and reach of the communication system. For example, since coherent systems encode information in the phase of the light, the purer the light source is, the more information it can transmit.

The Miniaturization of Coherent Optics

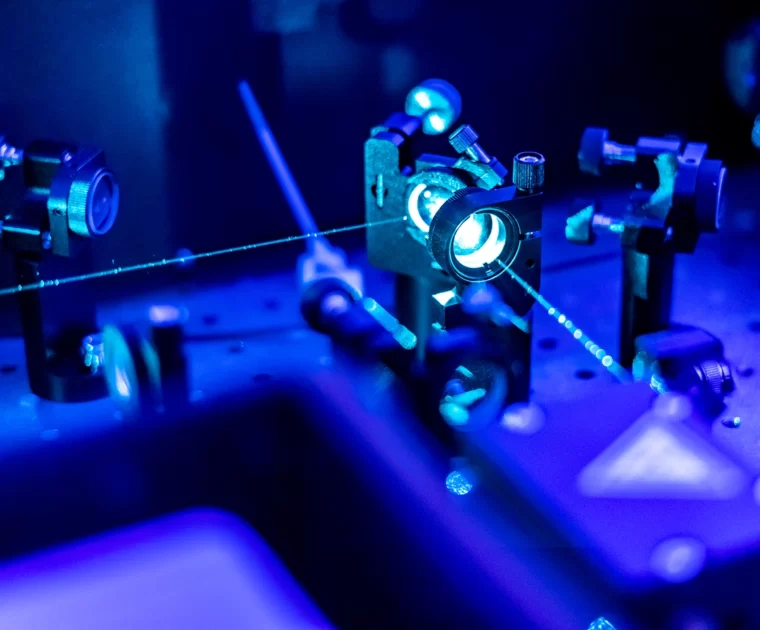

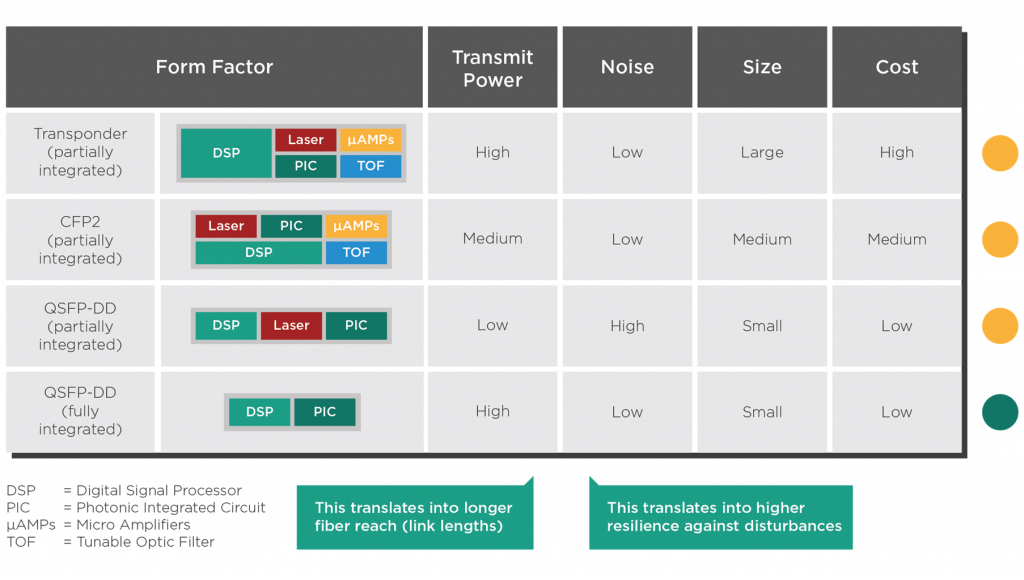

In the past, coherent communications were the domain of complicated benchtop systems with many discrete components that were cumbersome to connect. When Nortel (later Ciena) introduced the first commercial coherent transponder in 2008, the device was a bulky, expensive line card with discrete components distributed on multiple circuit boards. Such technology was reserved for premium long-distance links where performance is everything.

As time went by, coherent devices got smaller and consumed less power. By 2018, most coherent line card transponder functions could be miniaturized into CFP2 transceiver modules that were the size of a pack of cards and could plug into modules with pluggable line sides. QSFP modules followed a couple of years later, and they were essentially the size of a large USB stick and could be plugged directly into routers. This reduction in size, power, and cost, as well as the ever-rising data demands of telecom networks, has made coherent technology increasingly viable in metro and access networks.

Takeaways

Coherent optics transformed telecommunications, marrying complex theoretical foundations with practical engineering advancements to substantially enhance data transmission capacities and distances. The journey of coherent systems from benchtop experiments to the backbone of our digital infrastructure is an excellent example of how progress and evolution in optical communications work, always driven by the ever-increasing demands of our interconnected world.

EFFECT Photonics, with its focus on integrating advanced technologies like DSPs and tunable lasers into compact, efficient transceivers, strongly believes in making coherent optics more accessible and bringing them deeper into the network edge.

Tags: 1980s, 2005, always-evolving world of communications, breakthrough, coherent optics, cost-effective, deploy, economically viable, EFFECT Photonics, high capacity, high complexity, improve, improved, network core, network edge, optical fiber communications, optical networks, optical transmission reach, Photonics, receivers, spread out, studied extensively, systems, technology, transition, transmit, vast distances, widely available

Transceiver Customization for Flexible Access Networks

Let’s be honest: not every optical network problem can be solved by scaling up capacity.…

Let’s be honest: not every optical network problem can be solved by scaling up capacity. It’s not always cost-effective, and it’s not always sustainable. Providers and operators who want to become market leaders must scale up while also learning to allocate their existing network resources most efficiently and dynamically. For example, they must monitor their network performance frequently, providing more energy and capacity to high-traffic links while reducing power and capacity in areas with little traffic. They must find hardware that fits the rest of their network devices to a tee instead of equipment that is over- or under-specified.

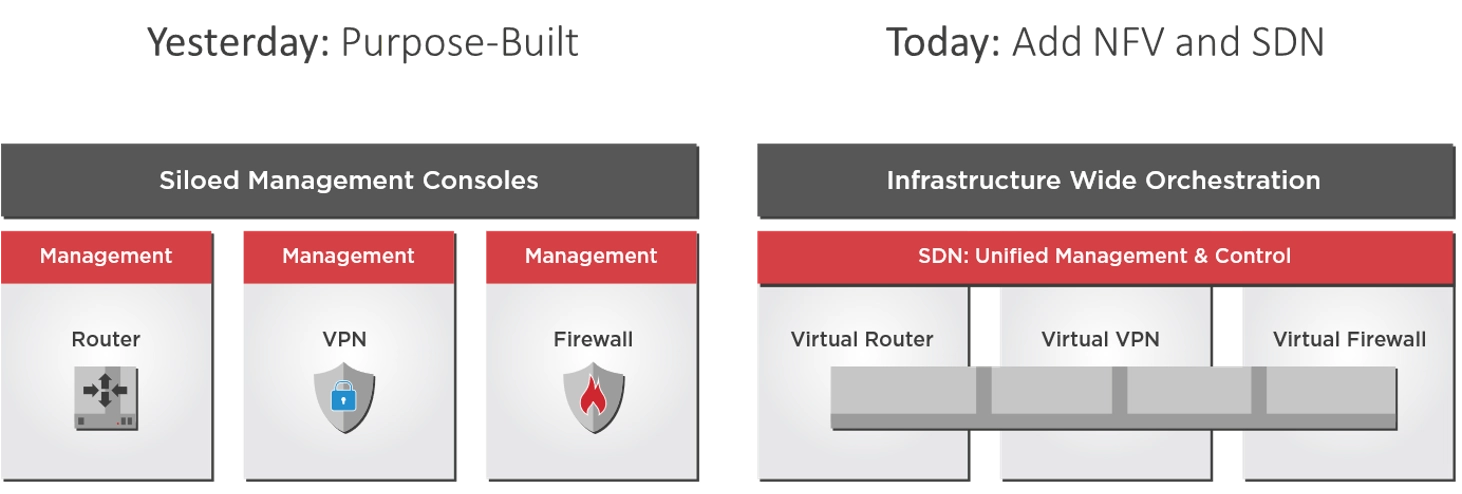

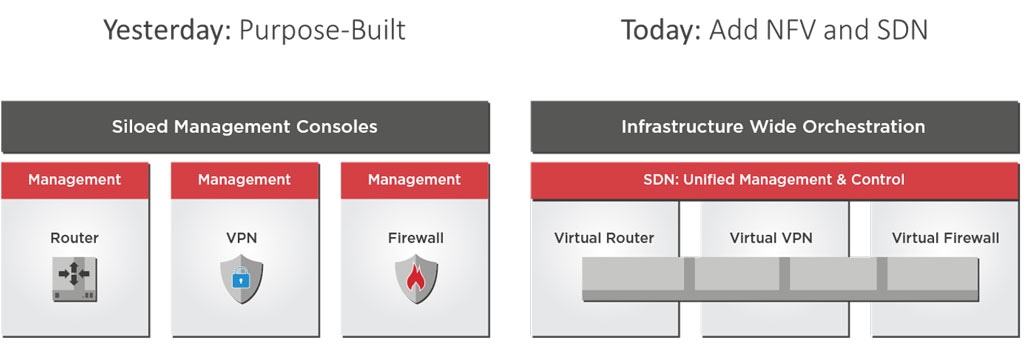

Operators usually change settings in the higher network layers to adjust their networks dynamically. For example, artificial intelligence in network layer management will become a major factor in reducing the energy consumption of telecom networks. However, as networks get increasingly complex, operators need more degrees of freedom and knobs to adjust. They must customize the network and physical layers to fit the network best.

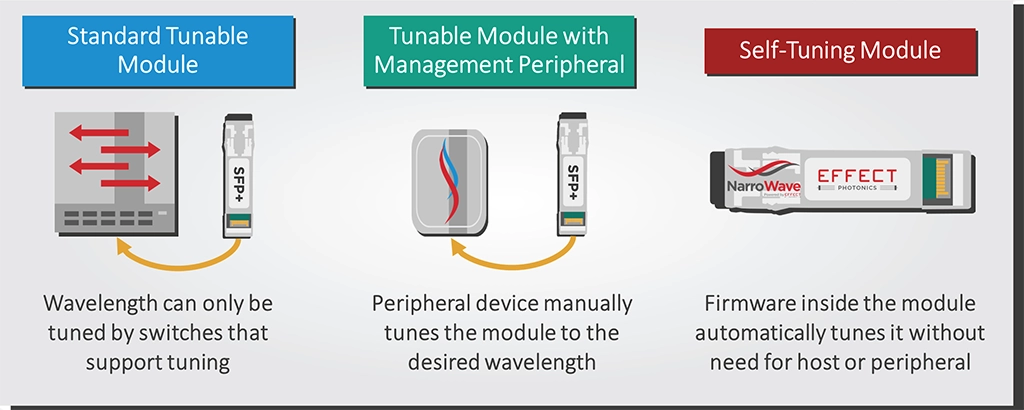

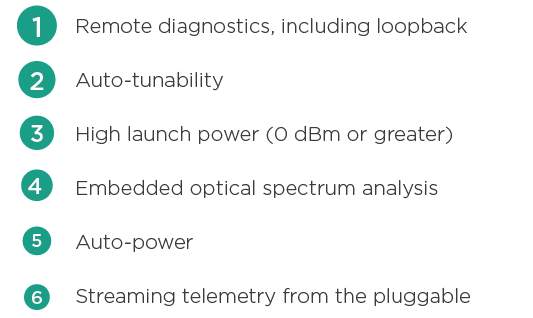

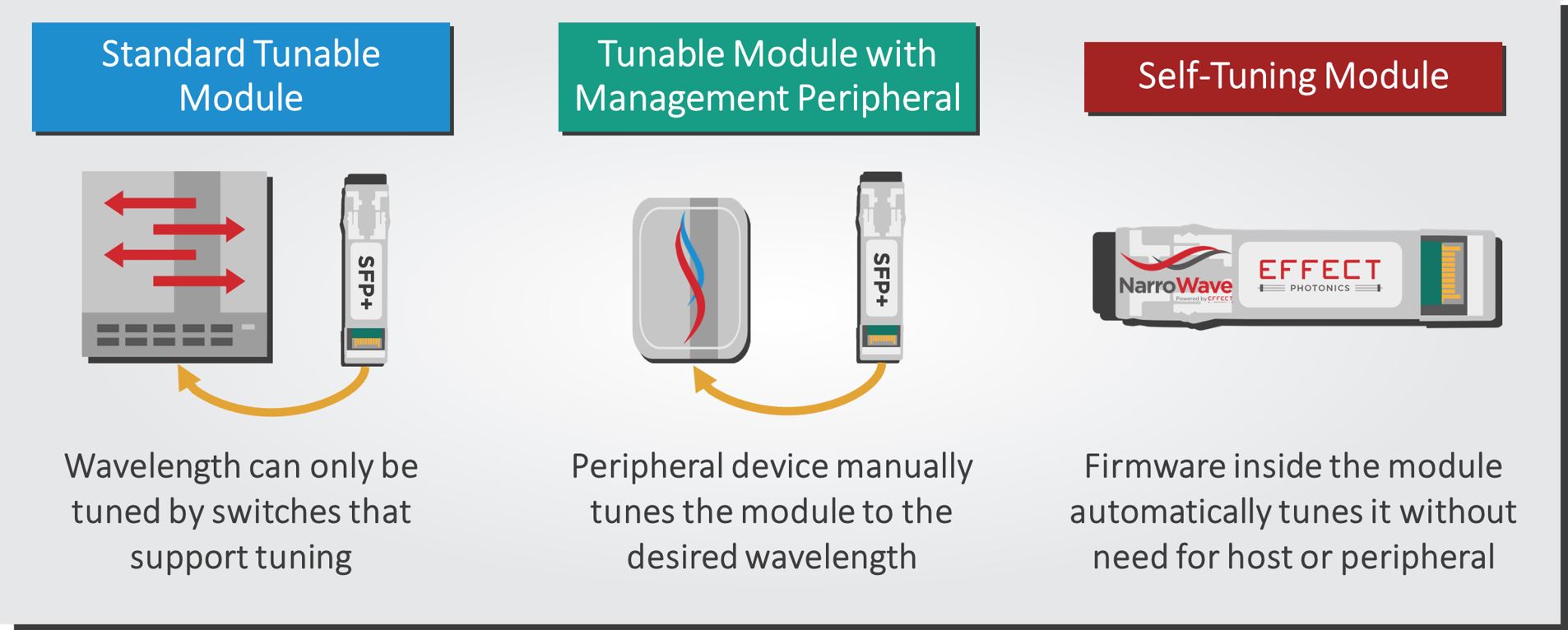

Fortunately, the new generation of pluggable transceivers gives operators more customization options than ever to change physical layer settings and adapt to these changing and growing network requirements and use cases. In this article, we will provide examples from our own pluggable transceivers and NarroWave technology.

Customization for Remote Diagnostics and Management

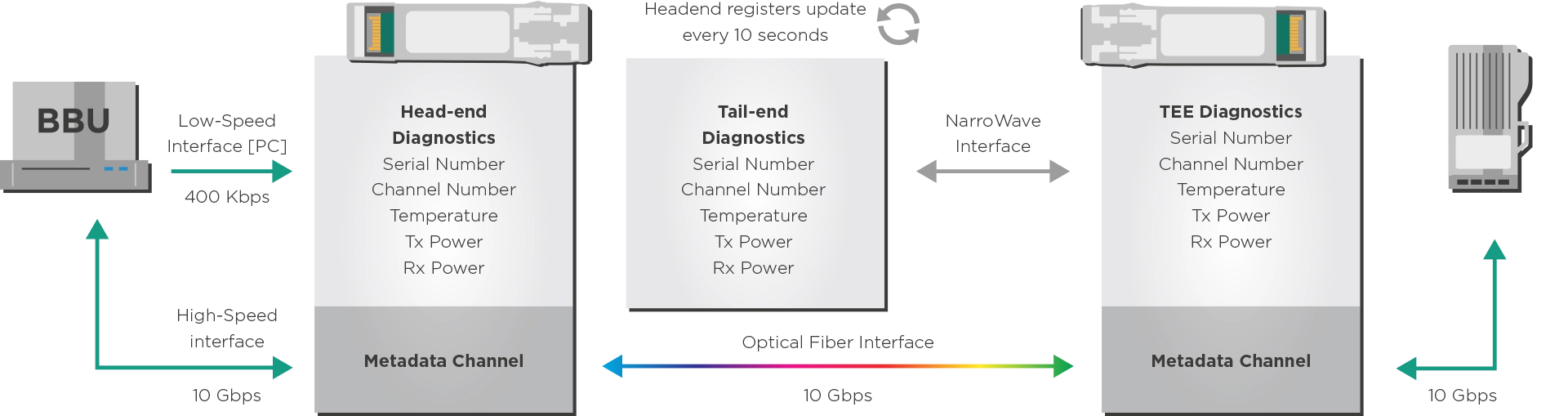

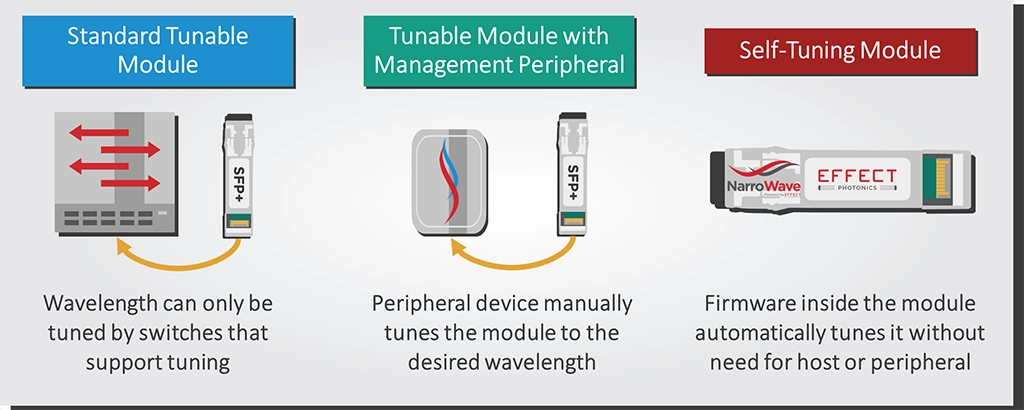

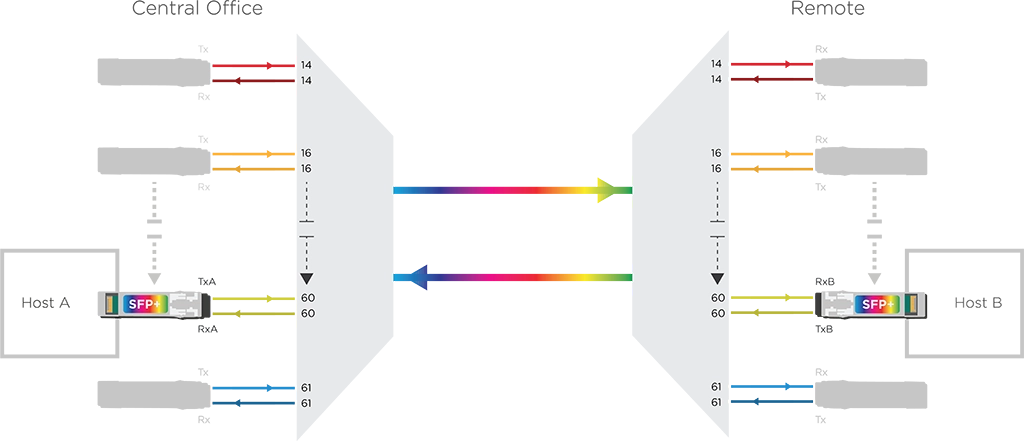

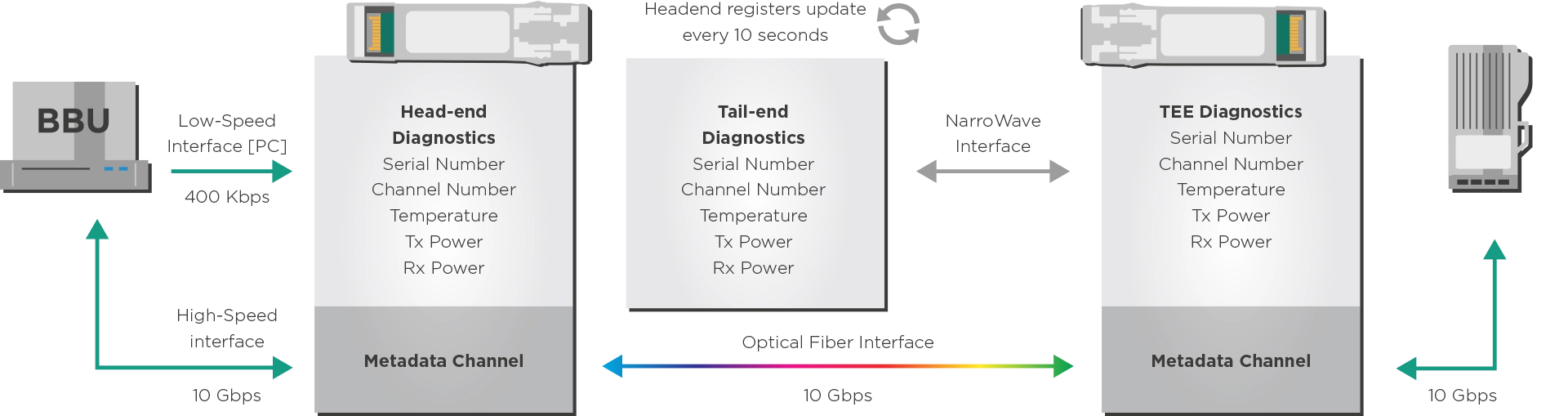

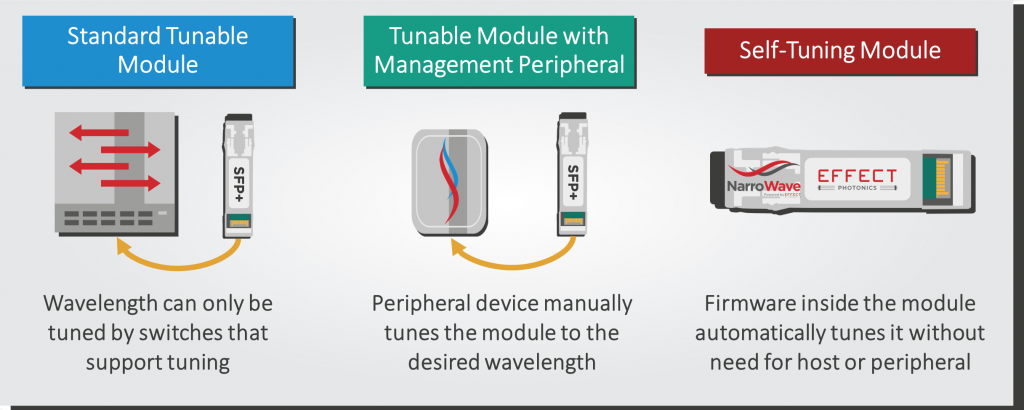

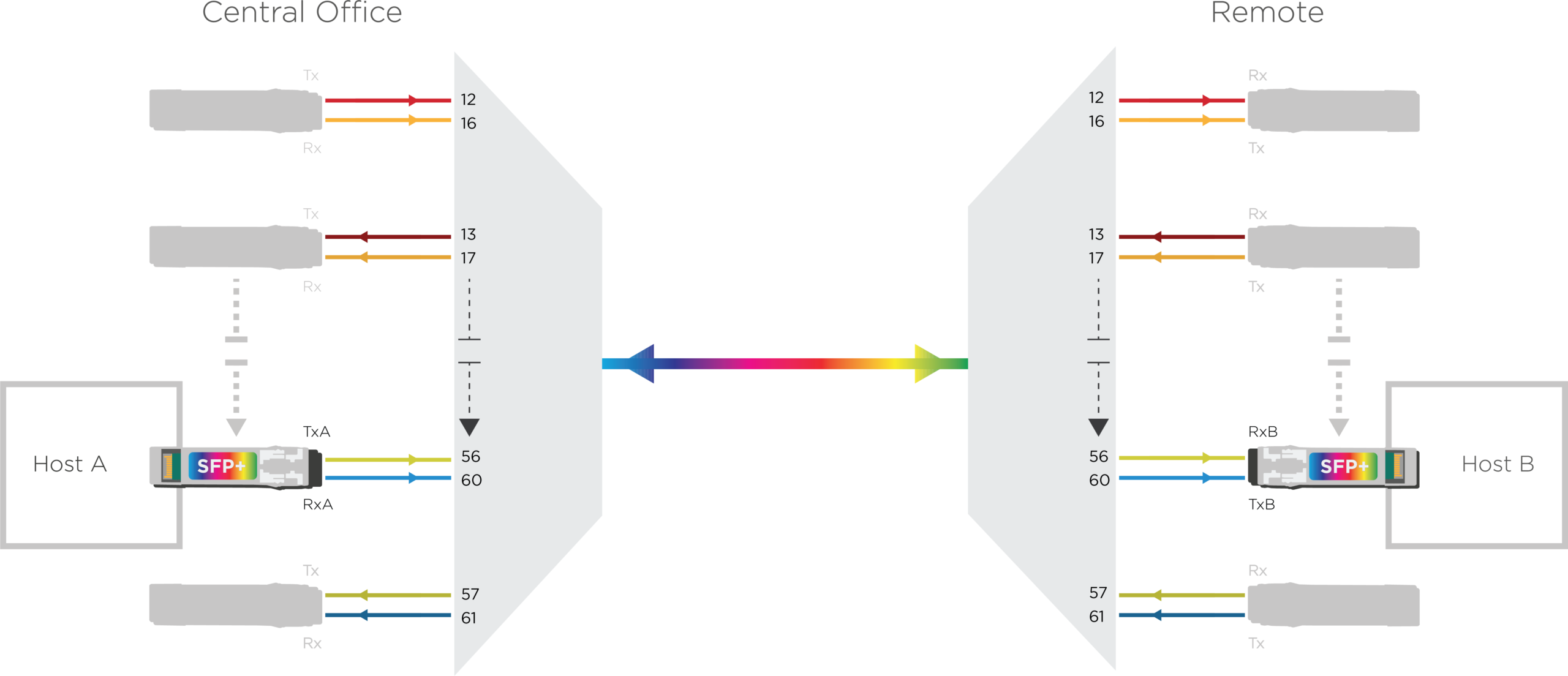

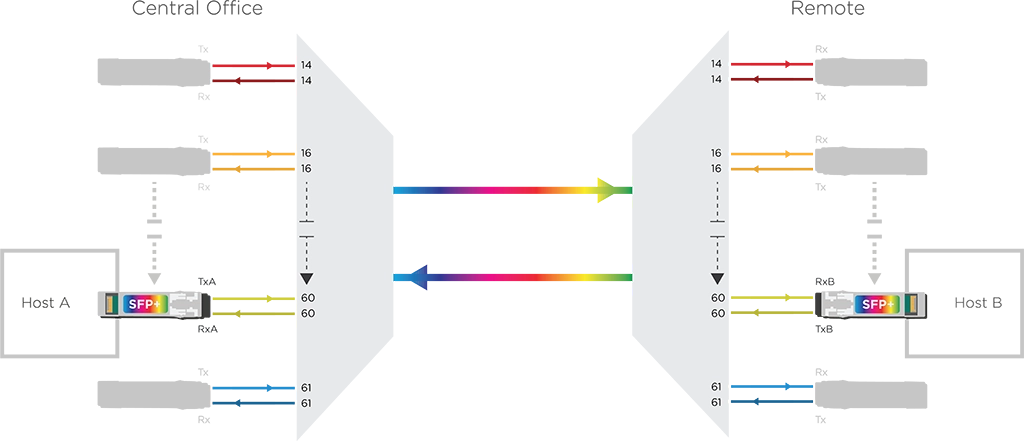

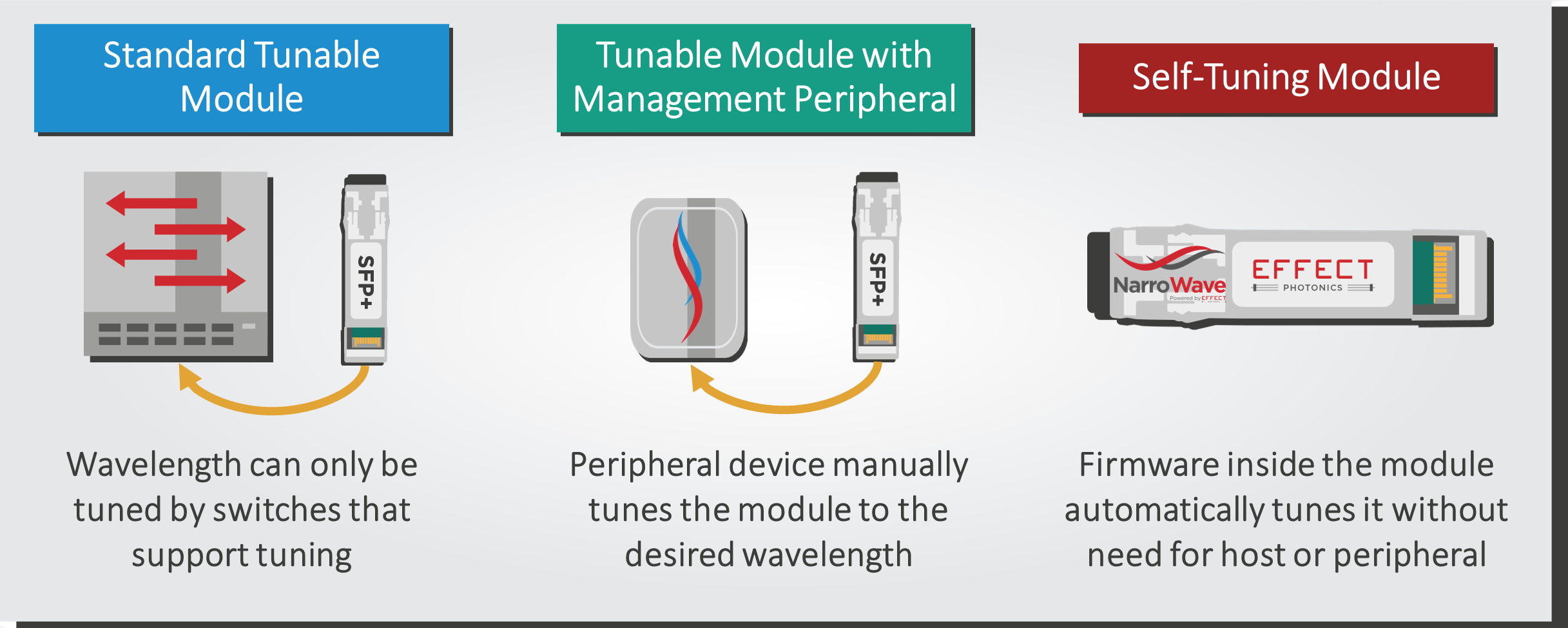

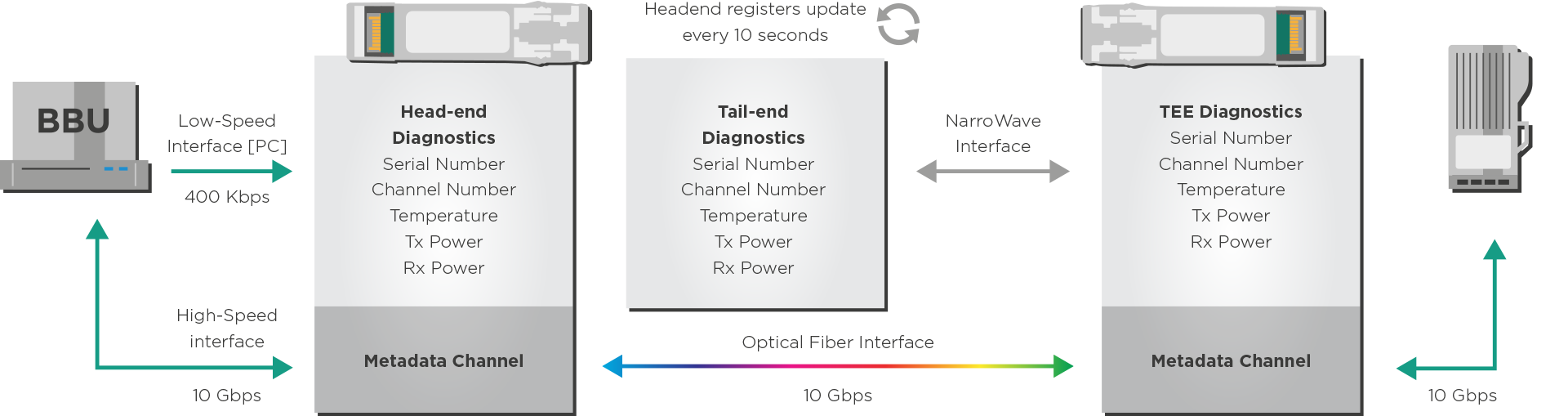

NarroWave sets up a separate low-frequency communication channel between two modules. This channel allows the headend module to remotely modify certain aspects of the tail-end module, effectively enabling several remote management and diagnostics options.

For example, the operator can remotely measure metrics such as the transceiver temperature and power transmitted and received. These metrics can provide a quick and useful health check of the link. The headend module can also remotely read alarms for low/high values of these metrics.

Even after buying the module, our customers can customize several variables, such as the low/high transmitter power levels, NarroWave self-tuning variables, memory behavior when turning on/off, or also the temperature and power flags and alarms. Customers also have the freedom to rewrite administrative information such as the vendor name, organization unique identifier (OUI), serial and part numbers, and passwords to access certain memory registers. These features are useful for system integrators and OEM sellers.

Customization for Easier Installation

Some of our transceiver features are customizations that make installation tasks easier. For example, setting up a network sometimes requires fibers to be repatched, which creates a loss of signal (LOS). Our NarroWave procedures include a customizable Ignore LOS (in seconds) flag that holds up the self-tuning scan and allows operators to perform maintenance duties without causing error messages at the host equipment.

These remote diagnostics and management features can eliminate certain truck rolls and save more operational expenses. They are especially convenient when dealing with very remote and hard-to-reach sites (e.g., an underground installation) that require expensive truck rolls.

Customization for Energy Sustainability

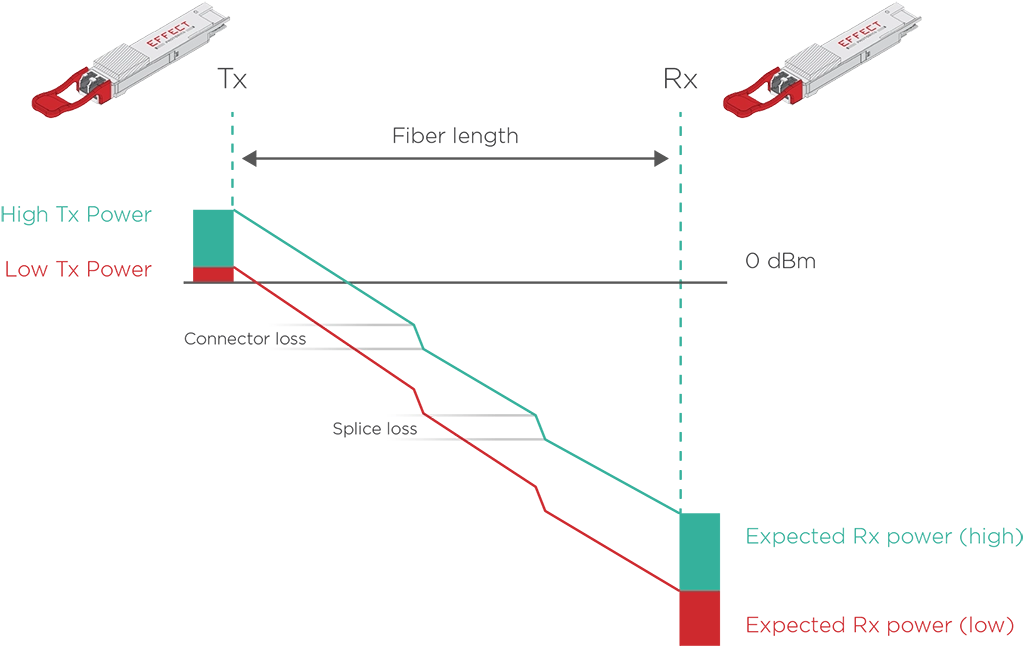

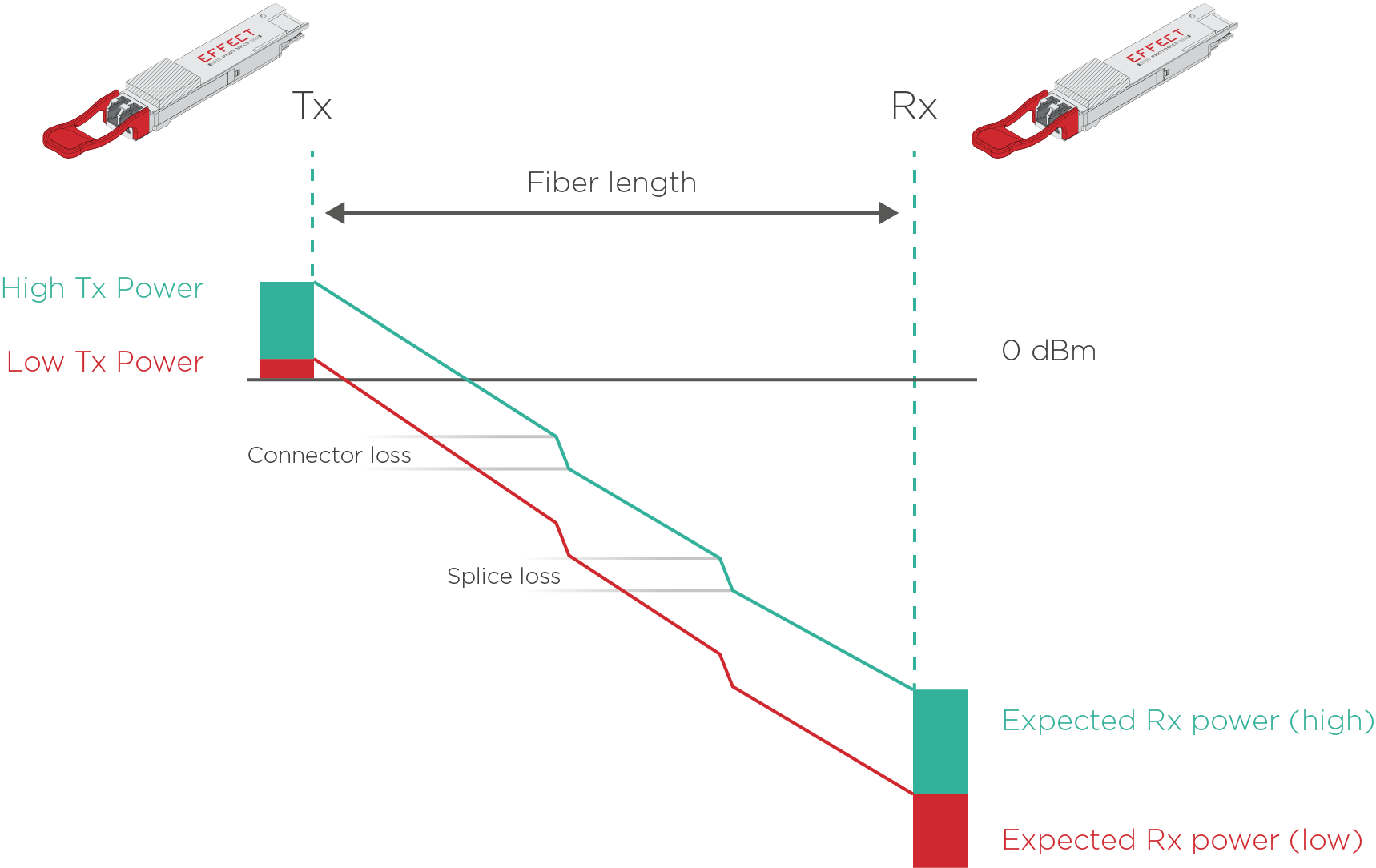

To talk about the impact of transceiver customization on energy sustainability, we first must review the concept of performance margins. This number is a vital measure of received signal quality and determines how much room there is for the signal to degrade without impacting the error-free operation of the optical link.

In the past, network designers have played it safe, maintaining large margins to ensure a robust network operation in different conditions. However, these higher margins usually require higher transmitter power and power consumption. Network management software can develop tighter, more accurate optical link budgets in real time that require lower residual margins through the remote diagnostics provided by this new generation of pluggable transceivers. This could lower the required transceiver powers and save valuable energy.

Another related sustainability feature is deciding whether to operate on low- or high-power mode depending on the optical link budget and fiber length. For example, if the transceiver needs to operate at its maximum 10G speed, it will likely need a higher performance margin and output power. However, if the operator uses the transceiver for just a 1G link, the transceiver can operate with a smaller residual margin and use a lower power setting. The transceiver uses energy more efficiently and sustainably by adapting to these circumstances.

Takeaways

Thanks to the advances in photonics and electronic integration, the new generation of pluggable transceivers has packaged many knobs and variables that previously required additional, specialized hardware that increased network complexity and costs. These advances give designers and operators more degrees of freedom than ever.

There are customizations that enable simpler remote management and diagnostics or easier installations. There are also customizable power settings that help the transceiver operate more sustainably. These benefits make access networks simpler, more affordable, and more sustainable to build and operate.

Tags: access networks, alarms, capacity, channel, cost-effective, customization options, customize, dynamically, EFFECT Photonics, efficiently, electronic integration, energy sustainability, fiber length, hardware, health check, high-traffic links, installation tasks, low-traffic areas, management, metrics, NarroWave technology, network devices, network management software, network resources, operational expenses, operators, optical network, performance margins, Photonics, Pluggable Transceivers, power, power consumption, providers, remote diagnostics, remote sites, Scaling up, Signal degradation, Sustainable

Coherent Transceivers at a Low Latency

Latency, the time it takes for data to travel from its source to its destination,…

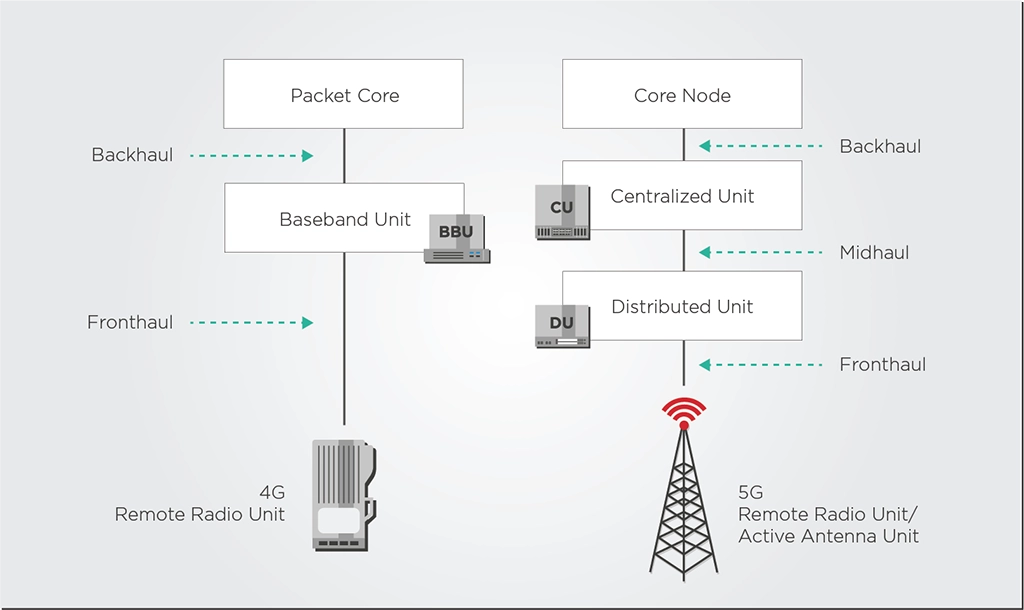

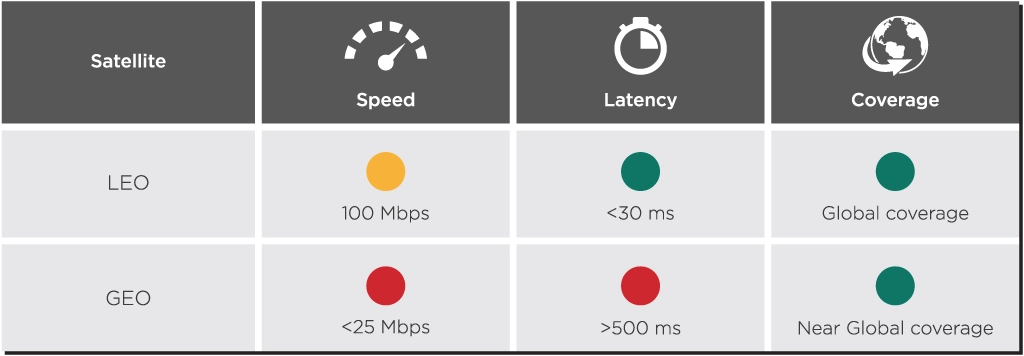

Latency, the time it takes for data to travel from its source to its destination, is a critical metric in modern networks. Reducing latency is paramount in the context of 5G and emerging technologies like edge computing.

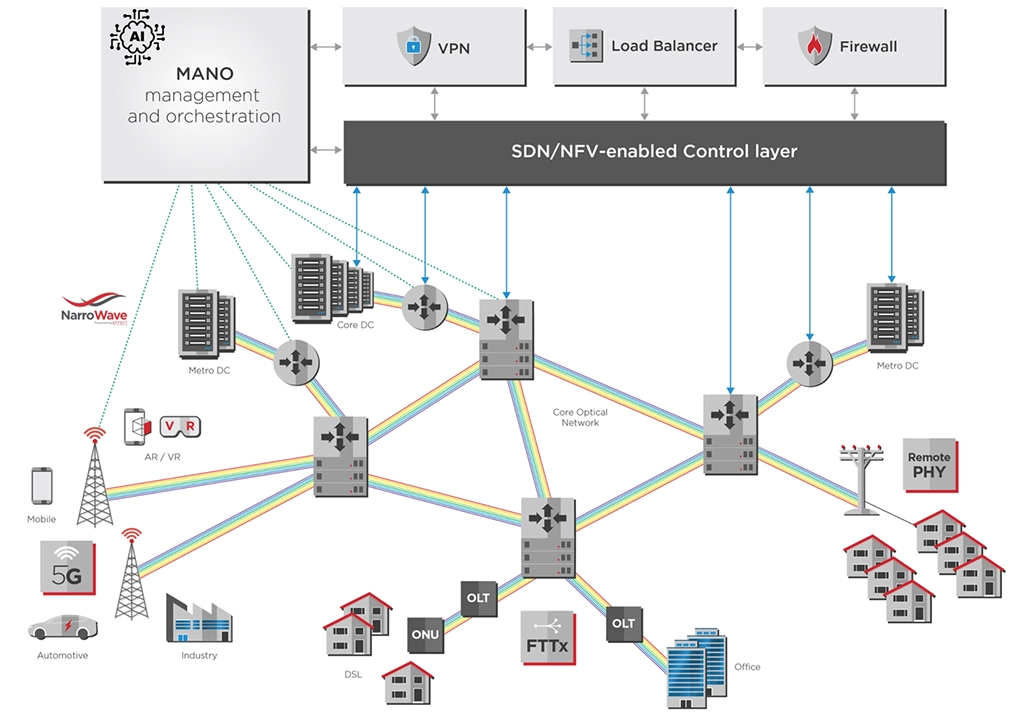

Smaller data centers placed locally (also called edge data centers) have the potential to minimize latency, overcome inconsistent connections, and store and compute data closer to the end-user. Various trends are driving the rise of the edge cloud:

- 5G technology and the Internet of Things (IoT): These mobile networks and sensor networks need low-cost computing resources closer to the user to reduce latency and better manage the higher density of connections and data.

- Content delivery networks (CDNs): The popularity of CDN services continues to grow, and most web traffic today is served through CDNs, especially for major sites like Facebook, Netflix, and Amazon. By using content delivery servers that are more geographically distributed and closer to the edge and the end user, websites can reduce latency, load times, and bandwidth costs as well as increasing content availability and redundancy.

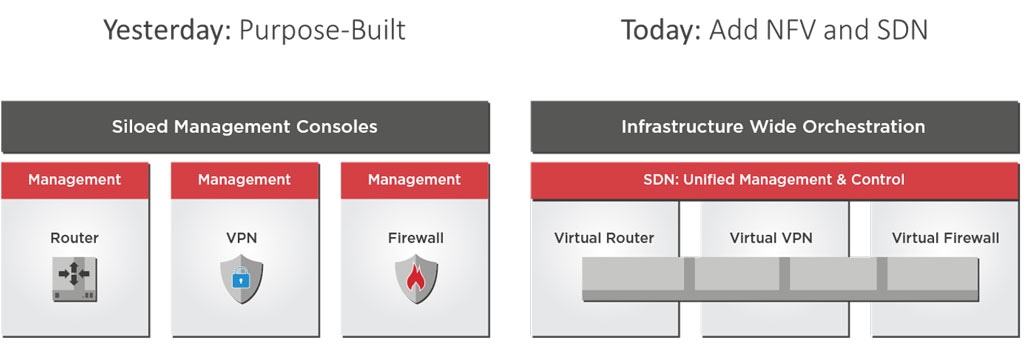

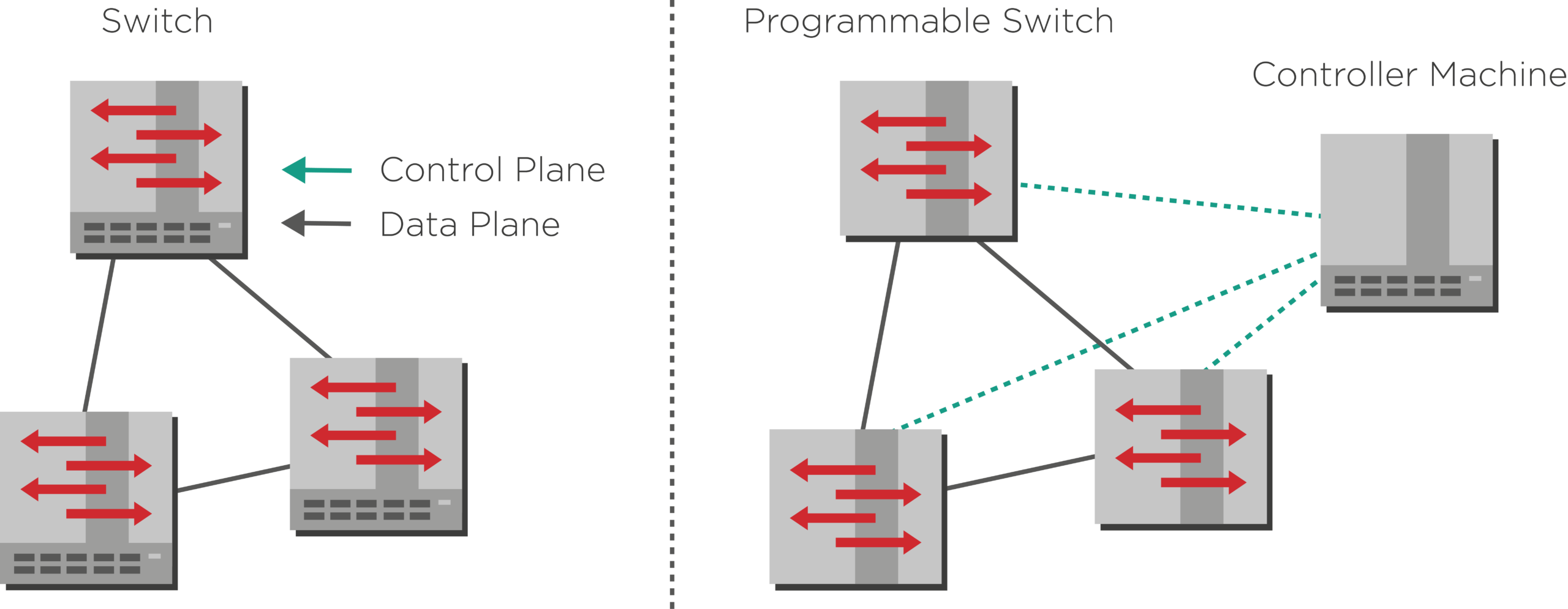

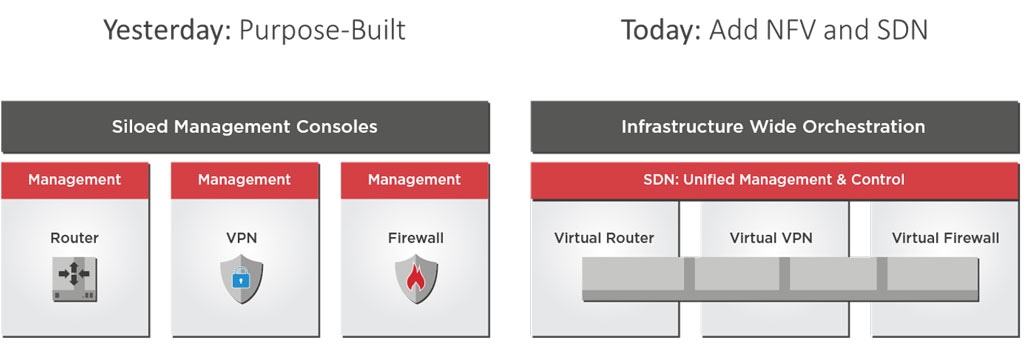

- Software-defined networks (SDN) and Network function virtualization (NFV): The increased use of SDNs and NFV requires more cloud software processing.

- Augment and virtual reality applications (AR/VR): Edge data centers can reduce streaming latency and improve the performance of AR/VR applications. Cloud-native applications are driving the construction of edge infrastructure and services. However, they cannot distribute their processing capabilities without considerable investments in real estate, infrastructure deployment, and management.

Several of these applications require lower latencies than before, and centralized cloud computing cannot deliver those data packets quickly enough. Let’s explore what changes are happening in edge networks to meet these latency demands and what impact will that have on transceivers.

The Different Latency Demands of the Cloud Edge

As shown in Table 1, a data center on a town or suburb aggregation point could halve the latency compared to a centralized hyperscale data center. Enterprises with their own data center on-premises can reduce latencies by 12 to 30 times compared to hyperscale data centers.

Types of Edge Data Centres

| Types of Edge | Data center | Location | Number of DCs per 10M people | Average Latency | Size | |

|---|---|---|---|---|---|---|

| On-premises edge | Enterprise site | Businesses | NA | 2-5 ms | 1 rack max | |

| Network (Mobile) | Tower edge | Tower | Nationwide | 3000 | 10 ms | 2 racks max |

| Outer edge | Aggregation points | Town | 150 | 30 ms | 2-6 racks | |

| Inner edge | Core | Major city | 10 | 40 ms | 10+ racks | |

| Regional edge | Regional edge | Regional | Major city | 100 | 50 ms | 100+ racks |

| Not edge | Not edge | Hyperscale | State/national | 1 | 60+ ms | 5000+ racks |

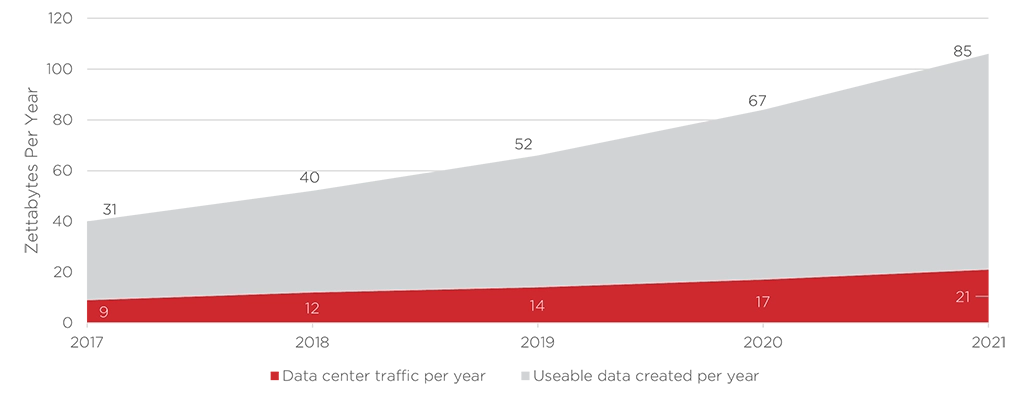

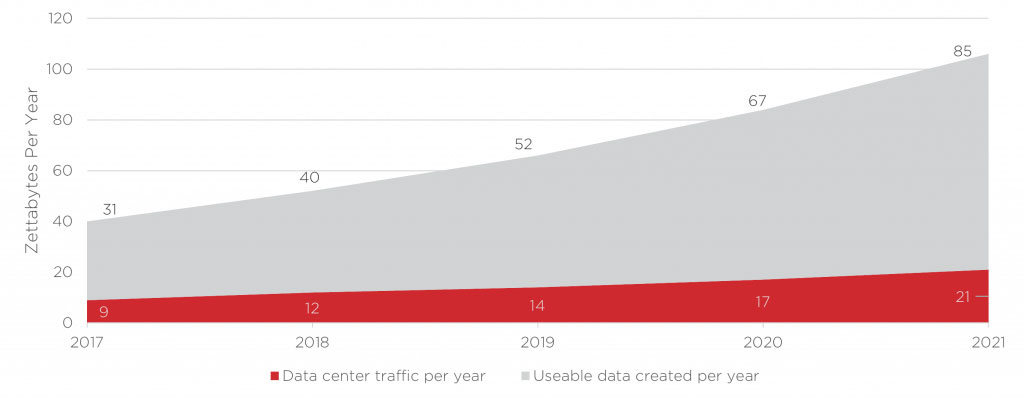

Cisco estimates that 85 zettabytes of useful raw data were created in 2021, but only 21 zettabytes were stored and processed in data centers. Edge data centers can help close this gap. For example, industries or cities can use edge data centers to aggregate all the data from their sensors. Instead of sending all this raw sensor data to the core cloud, the edge cloud can process it locally and turn it into a handful of performance indicators. The edge cloud can then relay these indicators to the core, which requires a much lower bandwidth than sending the raw data.

Using Coherent Technology in the Edge Cloud

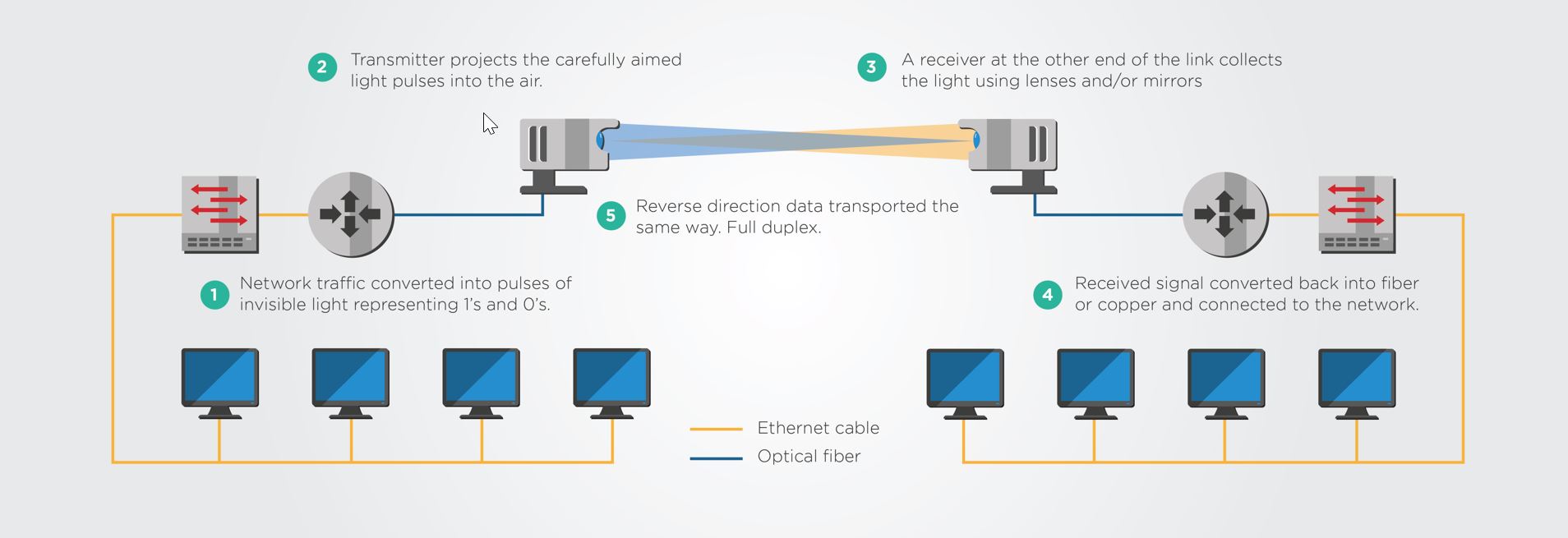

As edge data center interconnects became more common, the issue of interconnecting them became more prominent. Direct detect technology had been the standard in data center interconnects. However, reaching distances greater than 50km and bandwidths over 100Gbps required for modern edge data center interconnects required external amplifiers and dispersion compensators that increased the complexity of network operations.

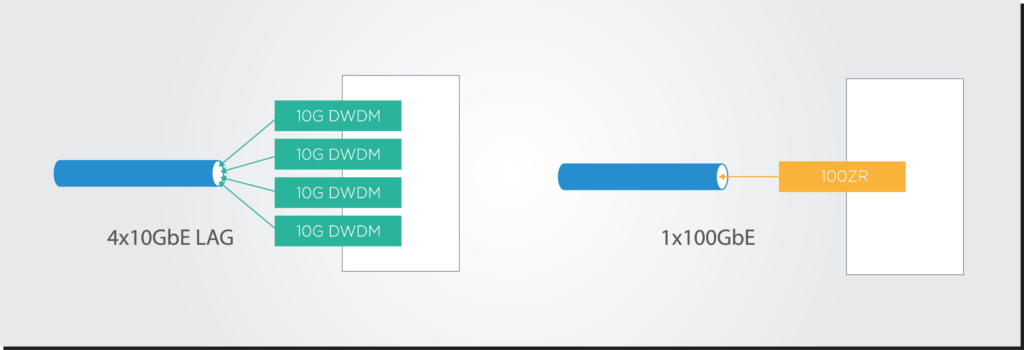

At the same time, advances in electronic and photonic integration allowed longer-reach coherent technology to be miniaturized into QSFP-DD and OSFP form factors. This progress allowed the Optical Internetworking Forum (OIF) to create the 400ZR and ZR+ standards for 400G DWDM pluggable modules. With modules that are small enough to pack a router faceplate densely, the datacom sector could profit from a 400ZR solution for high-capacity data center interconnects of up to 80km. The rise of 100G ZR technology takes this philosophy a step further, with a product aimed at spreading coherent technology further into edge and access networks.

How Does Latency in the Edge Affect DSP Requirements?

The traditional disadvantage of coherent technology vs direct detection is that coherent signal processing takes more time and computational resources and, therefore, introduces more latency in the network. Adapting to the latency requirements of the network edge might, especially in shorter link distances, might require digital signal processors (DSPs) to adopt a “lighter” version of the signal processing normally used in coherent technology.

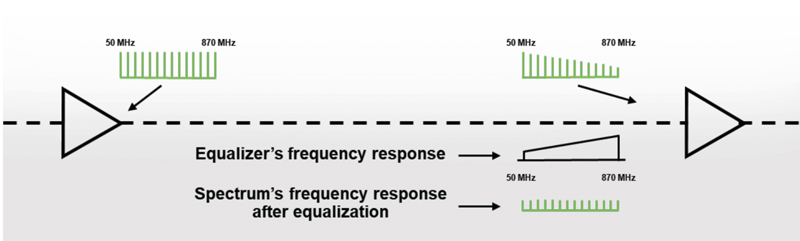

Let’s give an example of how DSPs could behave differently in these cases. The quality of the light signal degrades when traveling through an optical fiber by a process called dispersion. The same phenomenon happens when a prism splits white light into several colors. The fiber also adds other distortions due to nonlinear optical effects.

These effects get worse as the input power of the light signal increases, leading to a trade-off. You might want more power to transmit over longer distances, but the nonlinear distortions also become larger, which beats the point of using more power. The DSP performs several operations on the light signal to try to offset these dispersion and nonlinear distortions.

However, shorter-reach connections require less dispersion compensation, presenting an opportunity to streamline the processing done by a DSP. A lighter coherent implementation could reduce the use of dispersion compensation blocks. This significantly lowers system power consumption and latency too.

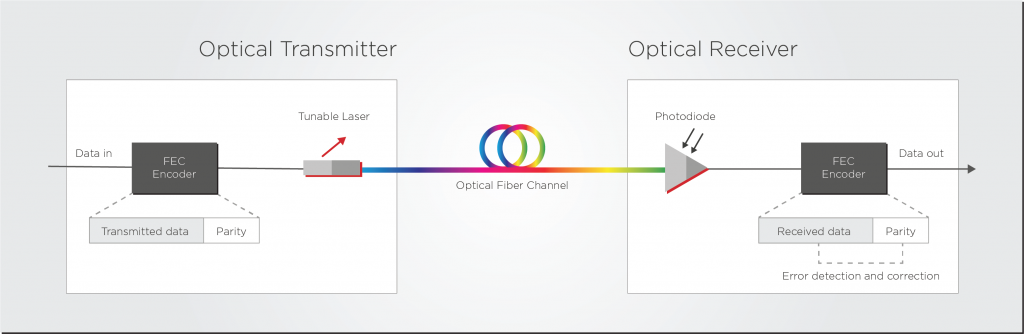

Another way to reduce processing and latency in shorter-reach data center links is to use less powerful forward error correction (FEC) in DSPs. You can learn more about FEC in one of our previous articles.

Takeaways

The shift towards edge data centers tries to address the low latency requirements in modern telecom networks. By decentralizing data storage and processing, closer to the point of use, edge computing reduces latency but also enhances the efficiency and reliability of network services across various applications, from IoT and 5G to content delivery and AR/VR experiences.

The use of coherent transceiver technology helps edge networks span longer reaches with higher capacity, but it also comes with the trade-off of increased latency due to more signal processing from the DSP. This scenario means that DSPs will have to reduce the use of certain processing blocks, such as dispersion compensation and FEC, to meet the specific latency requirements of edge computing.

Tags: 5G, applications, AR/VR, CDNs, cloud, data, data centers, demands, DSPs, Edge computing, EFFECT Photonics, infrastructure, latency, Networks, NFV, processing, SDN, services, technology, Transceivers, trends

Making Smaller Lasers at a Big Scale

The world is moving towards tunability. The combination of tunable lasers and dense wavelength division…

The world is moving towards tunability. The combination of tunable lasers and dense wavelength division multiplexing (DWDM) allows datacom and telecom industries to expand their network capacity without increasing their existing fiber infrastructure. Furthermore, the miniaturization of coherent technology into pluggable transceiver modules has finally enabled the widespread implementation of IP over DWDM solutions.

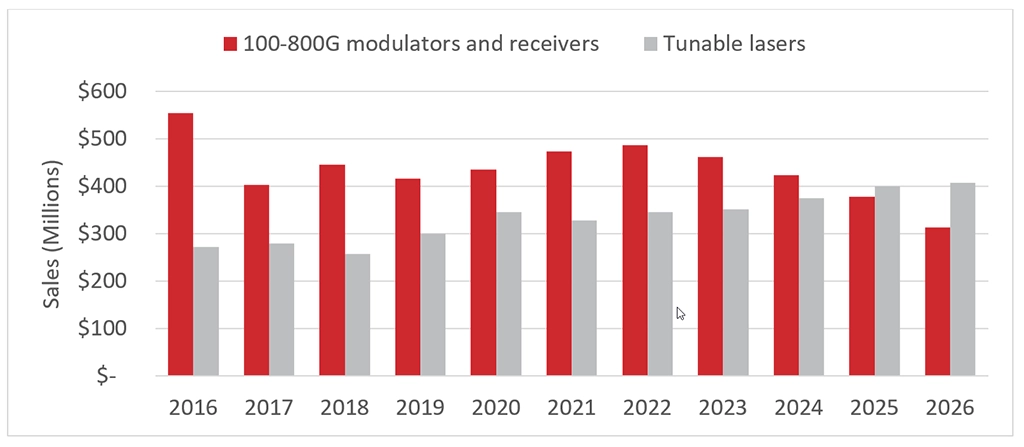

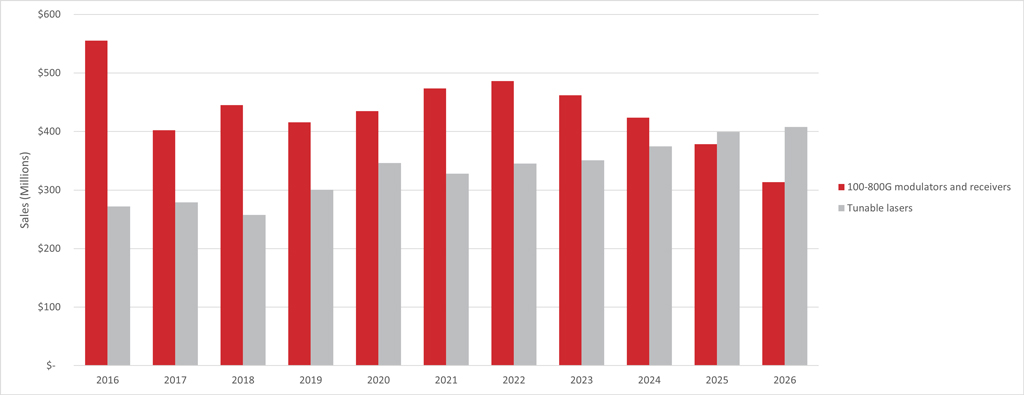

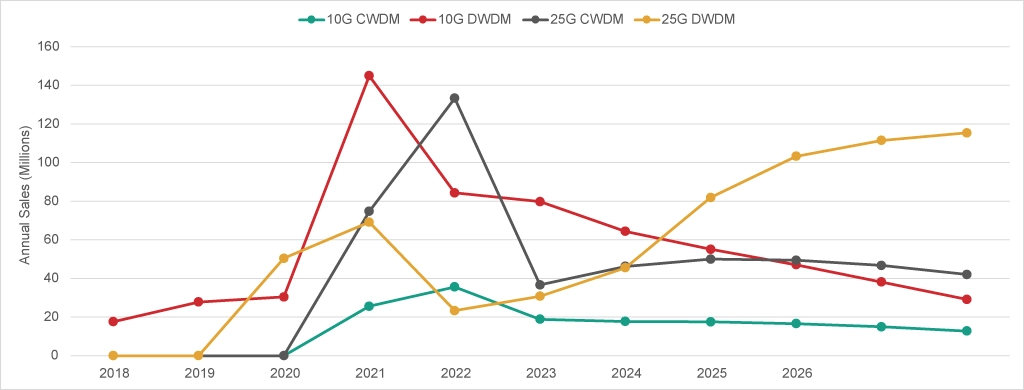

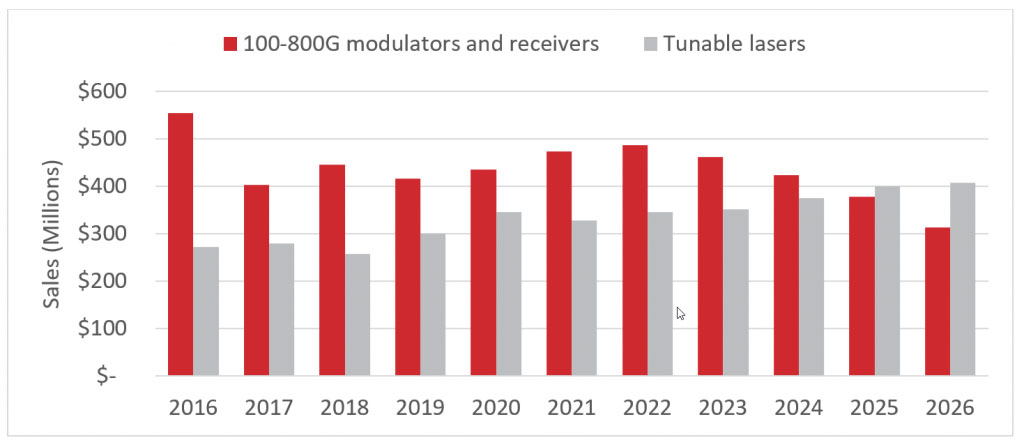

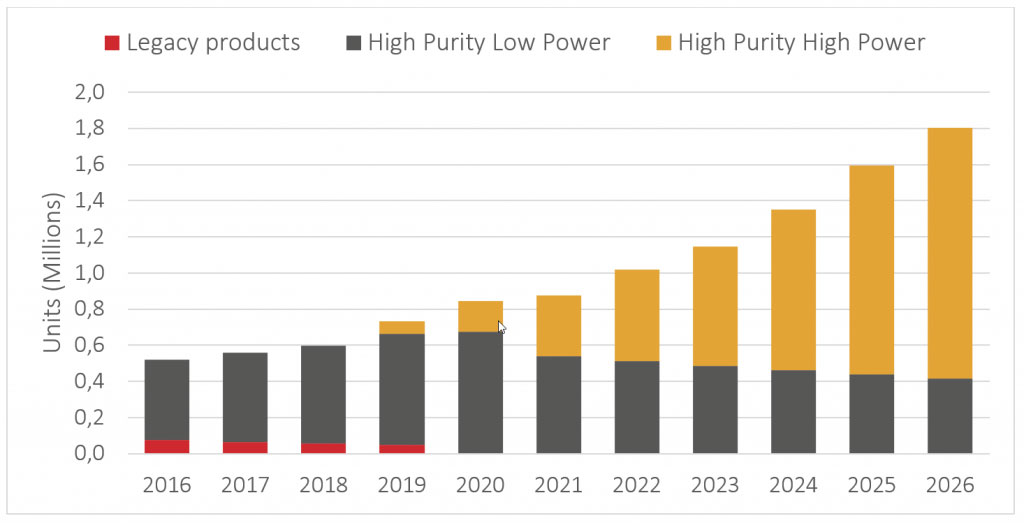

With the increasing demand for coherent transceivers, many companies have performed acquisitions and mergers that allow them to develop transceiver components internally and thus secure their supply. LightCounting forecasts show that while this consolidation will decrease the sales of modulator and receiver components, the demand for tunable lasers will continue to grow. The forecast expects the tunable laser market for the transceiver to reach a size of $400M in 2026.

East Asia is a huge driver of the rising number of tunable lasers sales. With initiatives like the “Broadband China” strategy and significant investments in 5G and beyond, the demand for advanced optical components, including tunable lasers, has surged in China. Japan and South Korea have a long history of adopting early new optical telecom innovations. After all, Japanese companies are at the forefront of research and development in tunable laser technology, and South Korea has built highly future-proofed 5G networks that are ahead of the implementations in Europe and North America. To meet the demands of this region, the industry needs to improve at making highly integrated tunable lasers at scale.

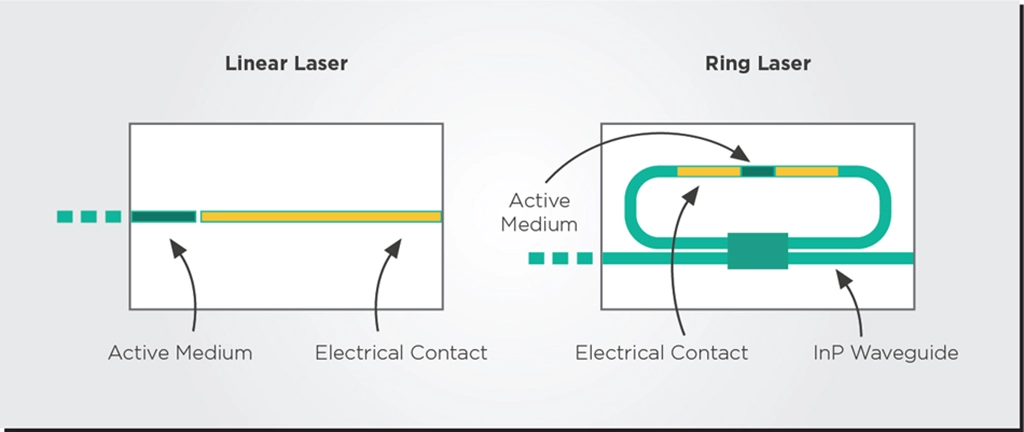

Making New and Smaller Lasers

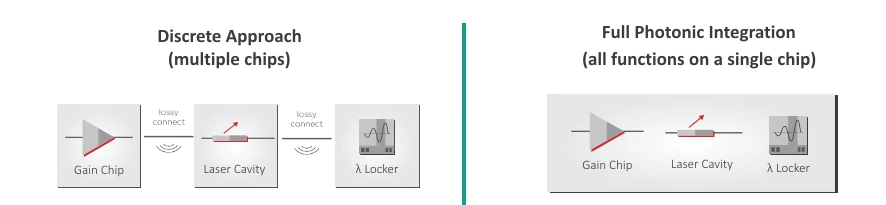

The impact of small and integrated lasers extends beyond mere size considerations; it crucially contributes to enhancing power efficiency. Smaller laser designs inherently operate at lower voltages and currents, offering improved heat dissipation and minimizing coupling losses. Photonic integration helps achieve these reductions, maximizing efficiency by consolidating multiple functions onto a single chip.

The journey towards 100G coherent technology in access networks requires compact and power-efficient coherent pluggables in the QSFP28 form factor and, with it, compact and power-efficient tunable lasers that fit this form factor.

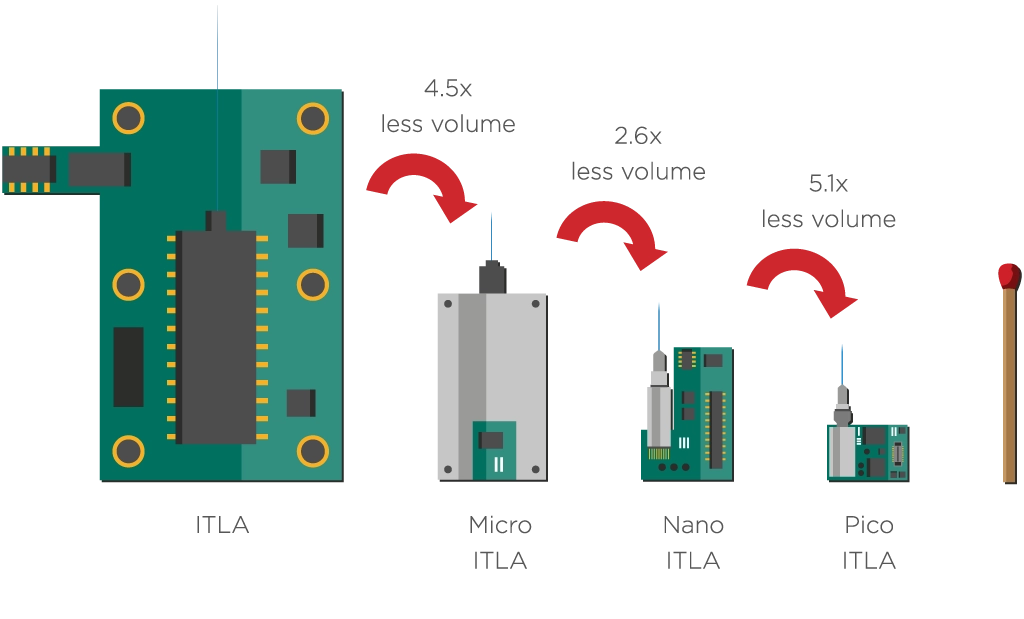

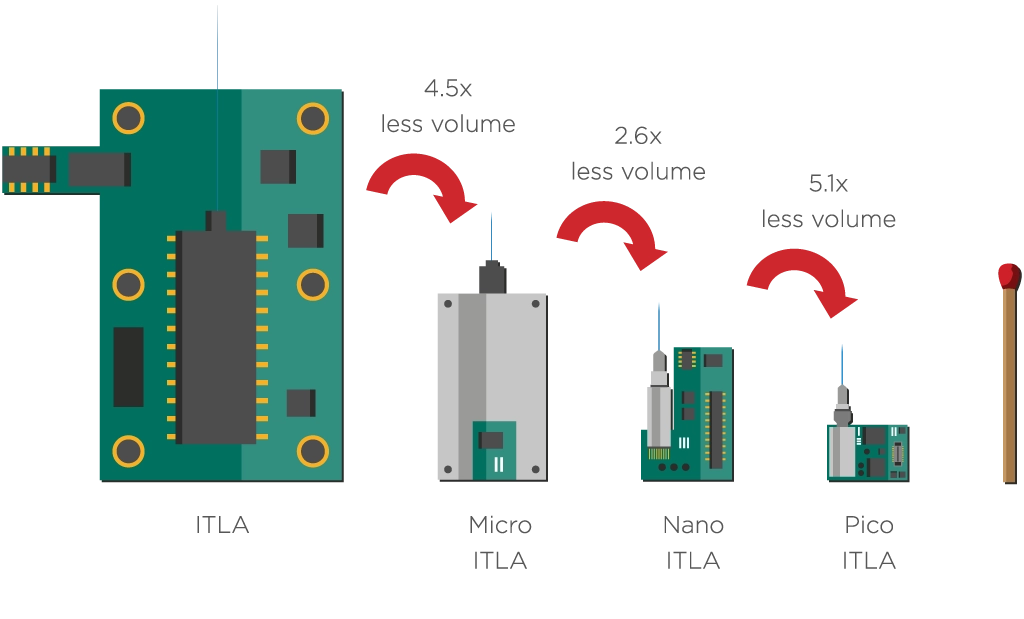

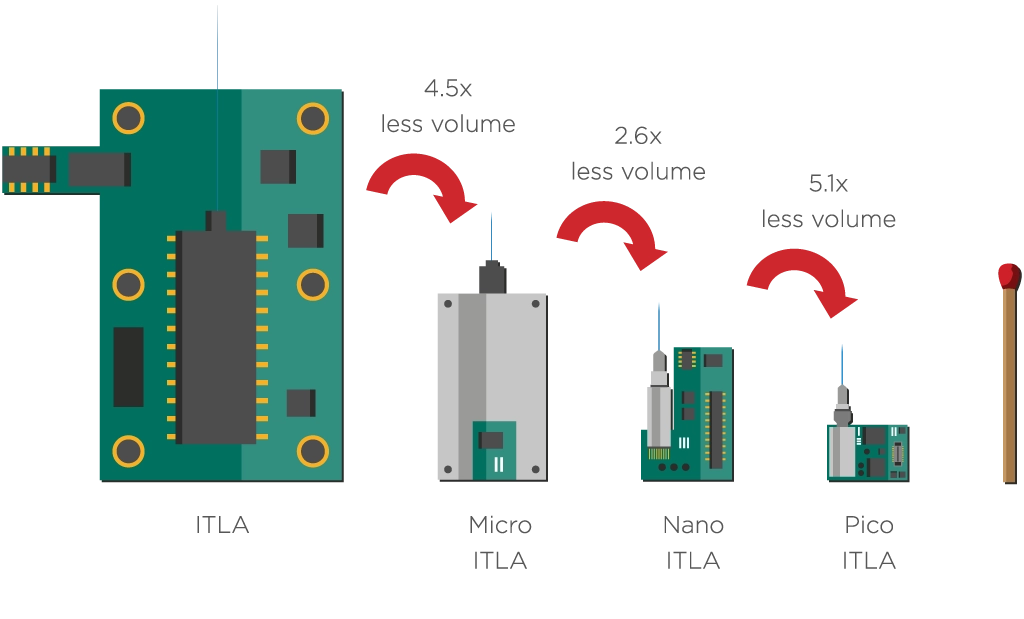

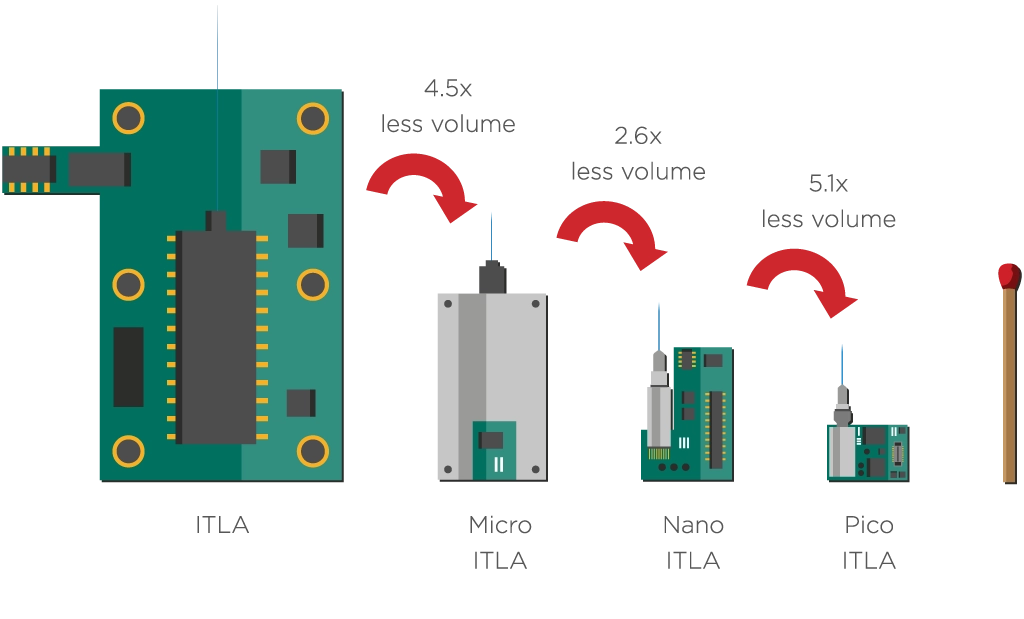

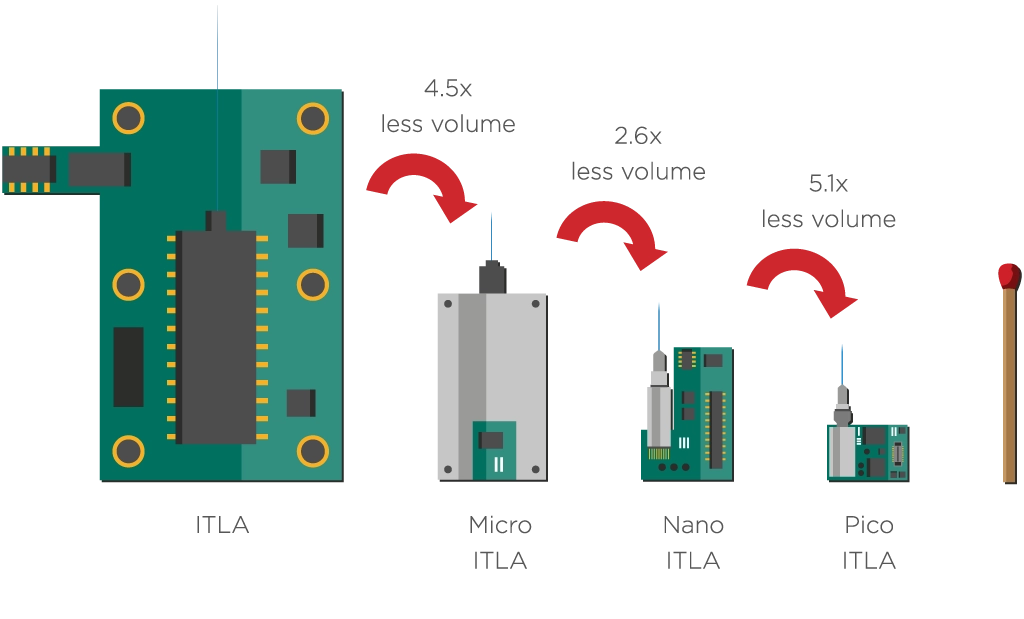

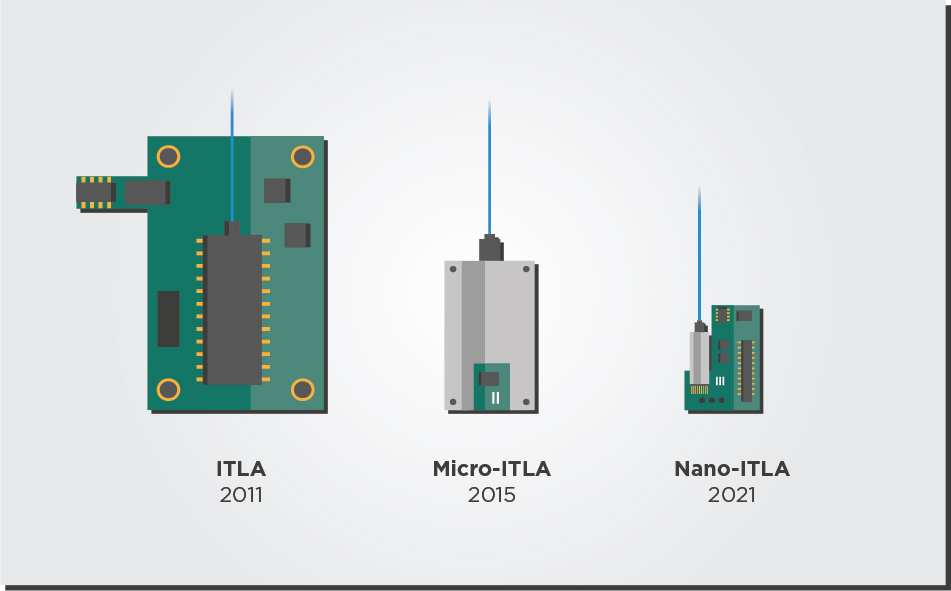

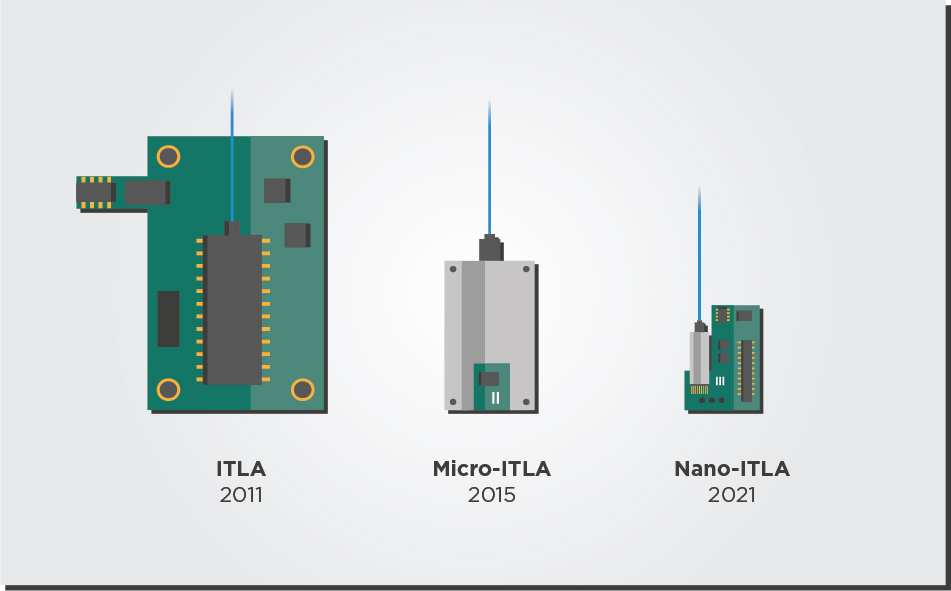

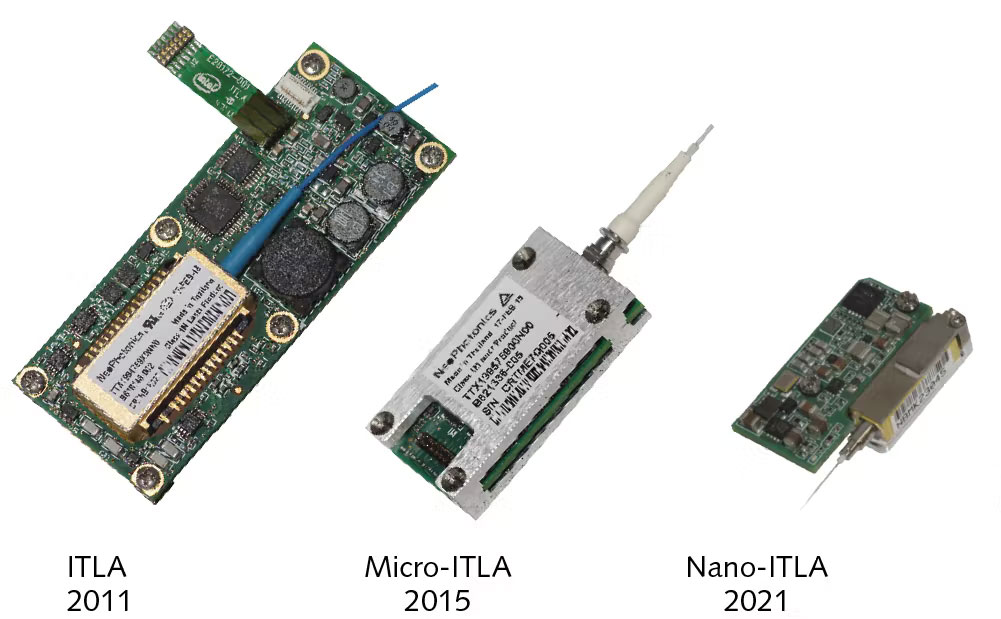

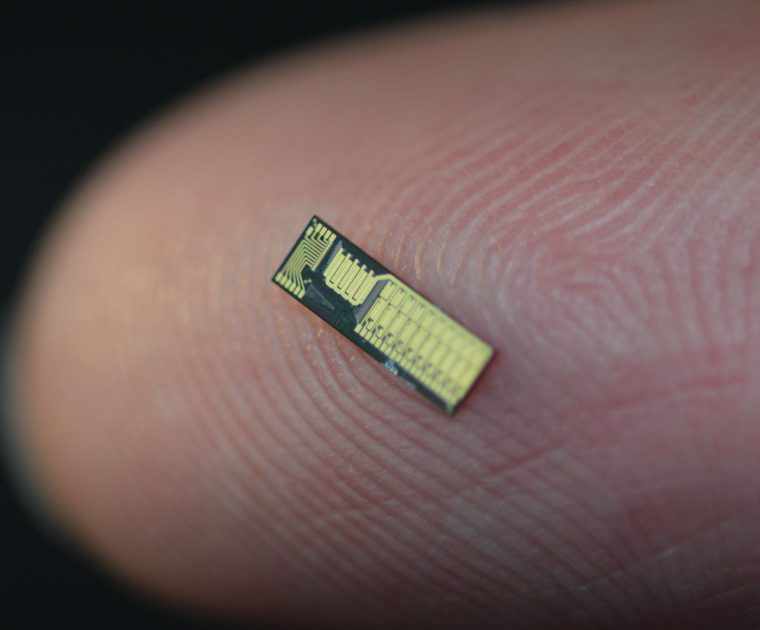

This monolithic integration of all tunable laser functions allowed EFFECT Photonics to develop a novel pico-ITLA (pITLA) module that will become the world’s smallest ITLA for coherent applications. The pITLA is the next step in tunable laser integration, including all laser functions in a package with just 20% of the volume of a nano-ITLA module. The figure below shows that even a standard matchstick dwarves the pITLA in size.

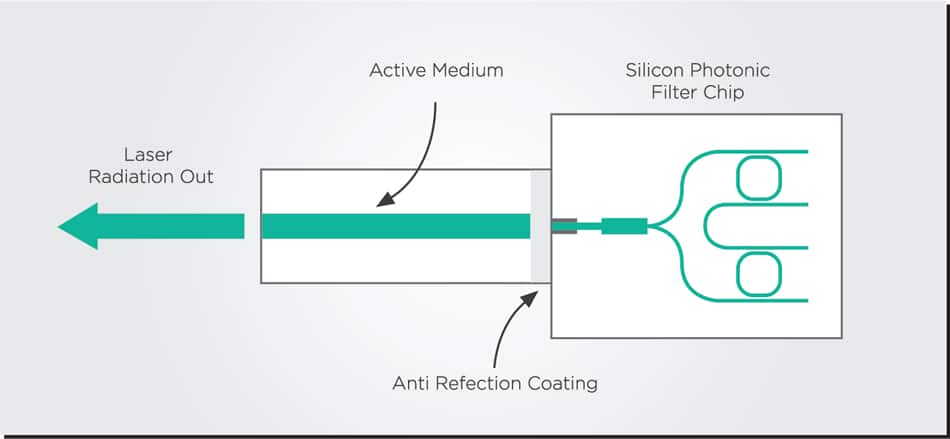

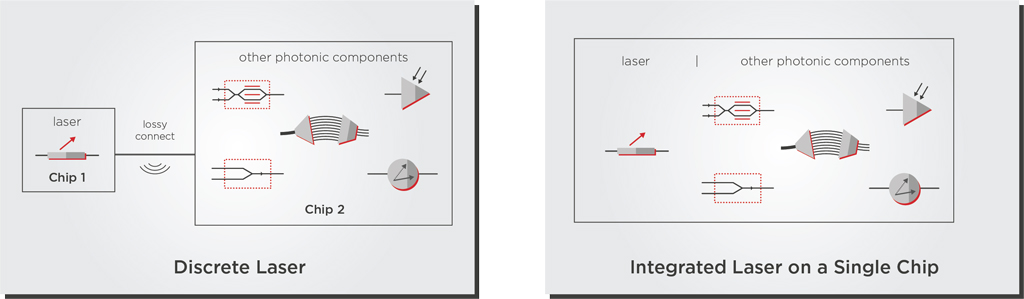

EFFECT Photonics’ laser solution is unique because it enables a widely tunable laser for which all its functions, including the wavelength locker, are monolithically integrated on a single chip. This setup is ideal for reducing power consumption and scaling into high production volumes.

The Economics of Scale

As innovative as these new, small lasers can be, they will have little impact if they cannot be manufactured at a high enough volume to satisfy the demands of mobile and cloud providers and drive down the cost per device.

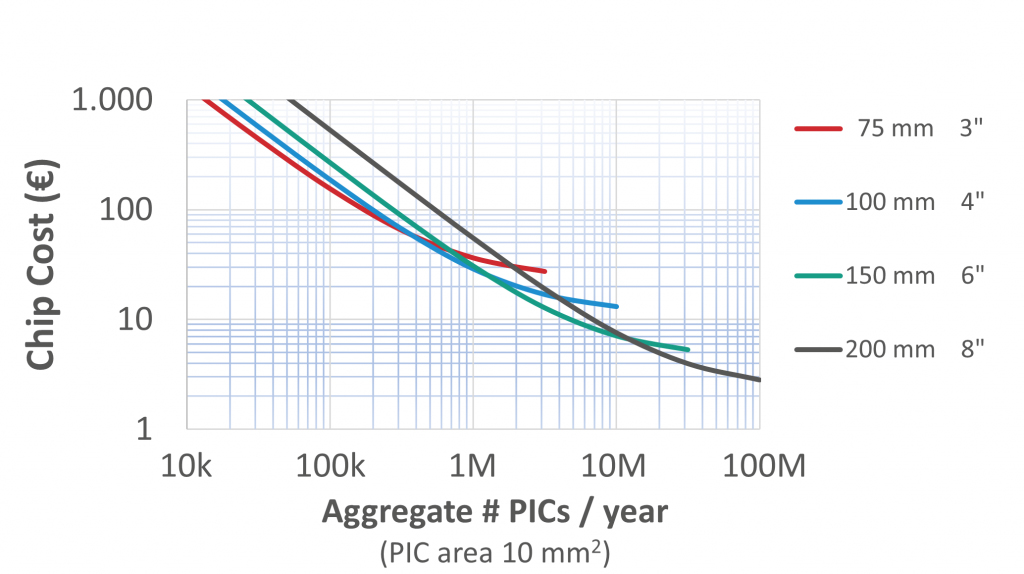

This economy-of-scale principle is the same one behind electronics manufacturing, and the same must be applied to photonics. The more optical components we can integrate into a single chip, the more can the price of each component decrease. The more optical System-on-Chip (SoC) devices can go into a single wafer, the more can the price of each SoC decrease.

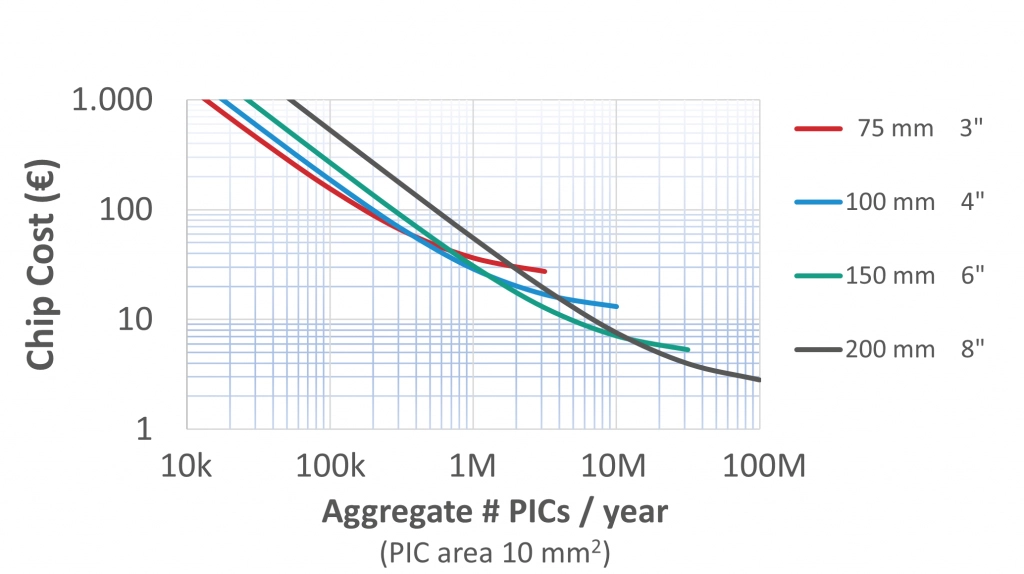

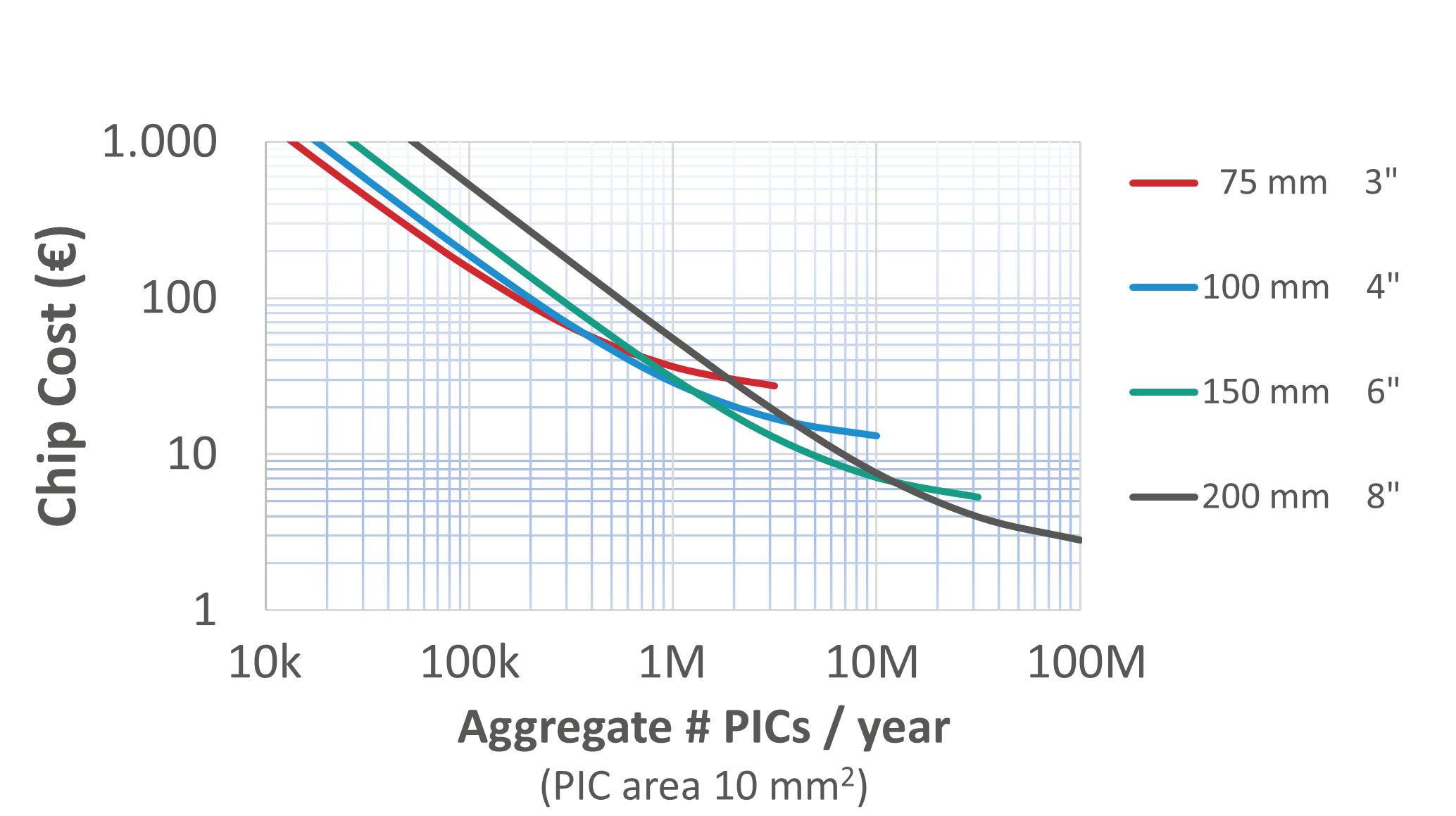

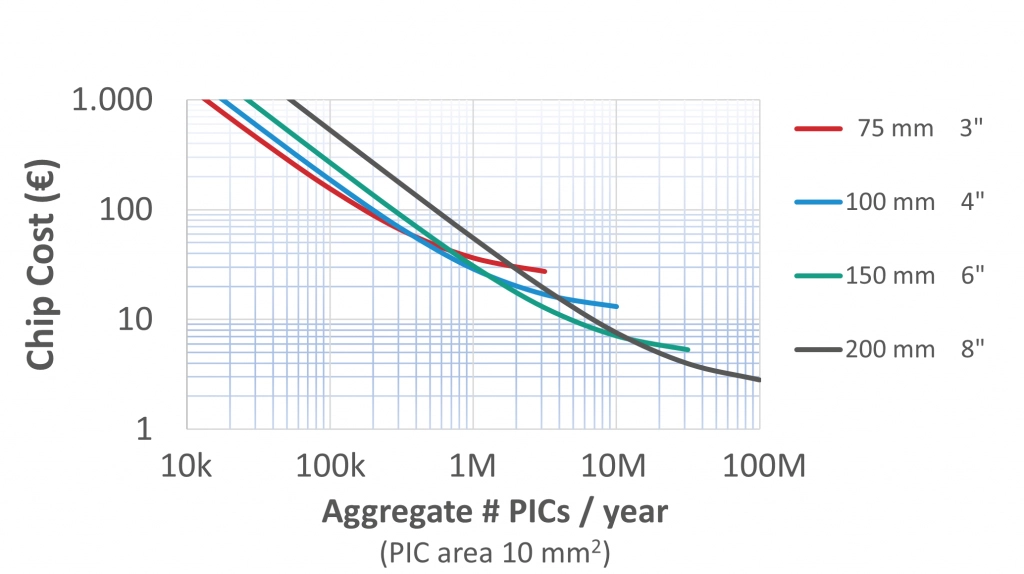

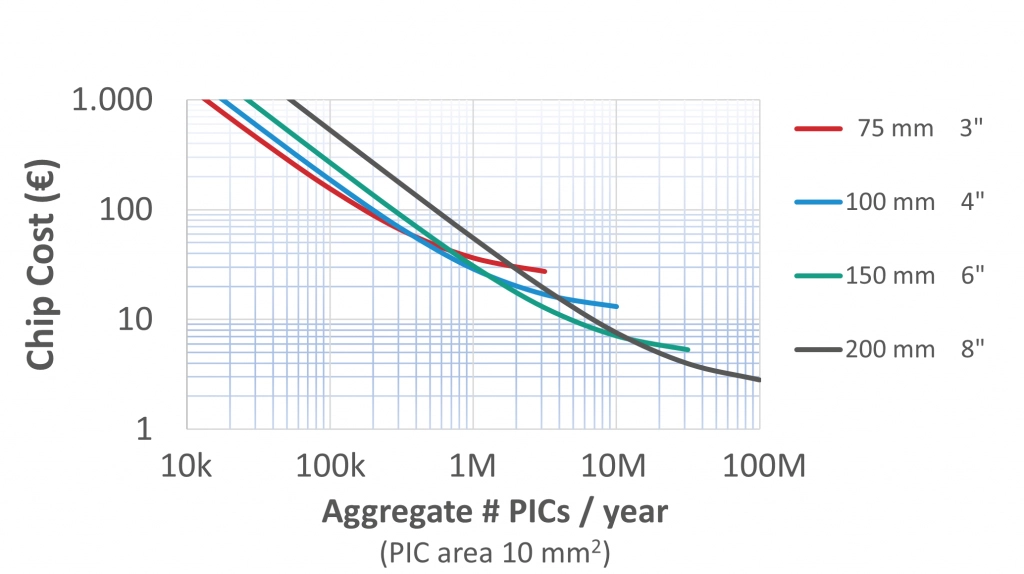

Researchers at the Technical University of Eindhoven and the JePPIX consortium have done some modelling to show how this economy of scale principle would apply to photonics. If production volumes can increase from a few thousands of chips per year to a few millions, the price per optical chip can decrease from thousands of Euros to mere tens of Euros. This must be the goal for the optical transceiver and tunable laser industry.

Learning to Scale from Electronics

A key way to improve photonics manufacturing is to learn from electronics packaging, assembly, and testing methods that are already well-known and standardized. After all, building a new special production line is much more expensive than modifying an existing production flow.

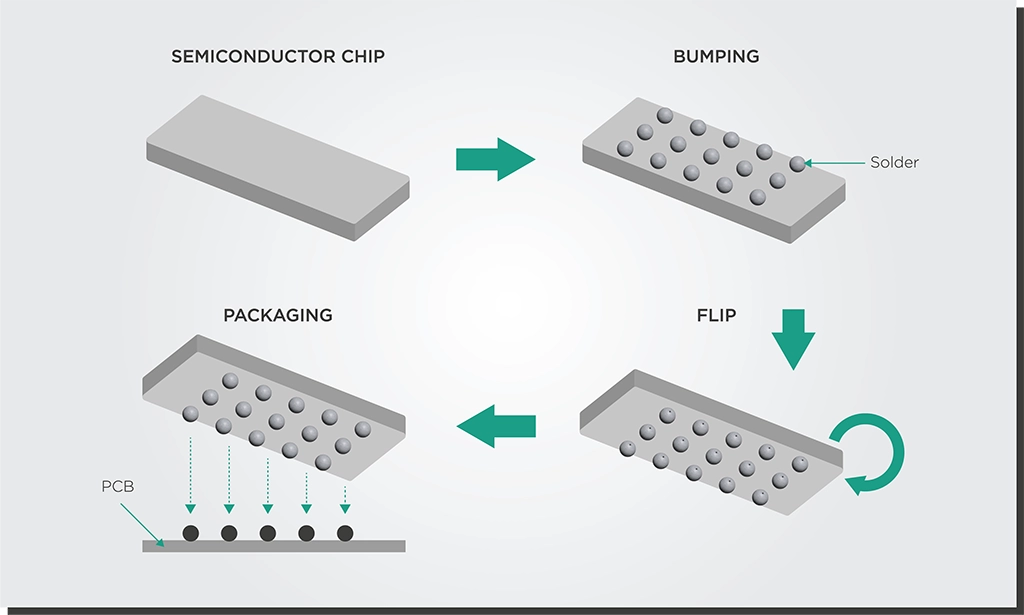

One electronic technique essential to transfer into photonics is ball-grid array (BGA) packaging. BGA-style packaging has grown popular among electronics manufacturers over the last few decades. It places the chip connections under the chip package, allowing more efficient use of space in circuit boards, a smaller package size, and better soldering.

Another critical technique to move into photonics is flip-chip bonding. This process is where solder bumps are deposited on the chip in the final fabrication step. The chip is flipped over and aligned with a circuit board for easier soldering.

Takeaways

As the demand for data and telecommunication services surges globally, the industry is moving towards more compact, power-efficient, and scalable laser solutions that integrate all necessary functions on a single chip. With East Asia driving the demand for these advanced components through their ambitious broadband and 5G initiatives, the challenge now lies in applying the economies of scale principle from electronics manufacturing to photonics. This approach would dramatically reduce costs and enable the mass adoption of these technologies.

Tags: 100G coherent technology, 5G Networks, access networks, acquisitions, ball-grid array, Broadband China strategy, Coherent technology, datacom, Dense wavelength division multiplexing, East Asia, economy-of-scale principle, EFFECT Photonics, electronics manufacturing, electronics packaging, Fiber Infrastructure, Flip-chip bonding, high production volumes, highly integrated tunable lasers, IP over DWDM solutions, JePPIX consortium, LightCounting forecasts, mergers, Network capacity, optical components, photonic integrated chip, photonic integration, Photonics, Pico-ITLA Module, Pluggable transceiver modules, power consumption, Power Efficiency, QSFP28 form factor, System-on-Chip devices, Technical University of Eindhoven, telecom industries, The world, transceiver components, tunable laser market, Tunable laser technology, tunable lasers, wafer, wavelength locker

What are Access Networks and Why Should We Care?

The evolution of telecommunications has led to the development of complex network architectures designed to…

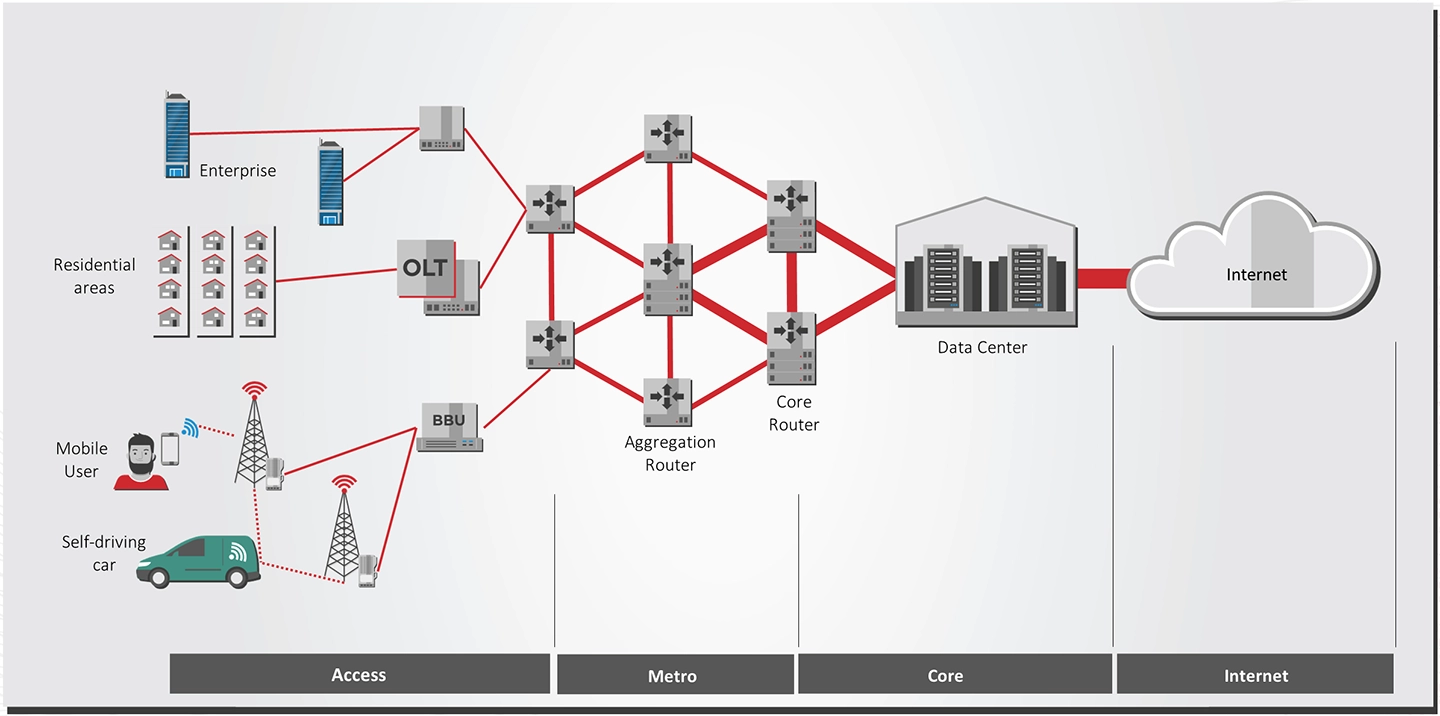

The evolution of telecommunications has led to the development of complex network architectures designed to meet data transmission needs across the globe. In a very simplified way, we could segment a typical network architecture into three primary sections

- The core network: A backbone network itself, designed to provide high-speed, long-distance transmission across regions or countries.

- The metro network: This network binds the access network to the core network and is responsible for aggregating data from multiple access networks. It serves as an intermediary that enables the flow of data between local areas and the high-capacity backbone of the telecom network.

- The access network: This network is the link between end-users and the broader telecommunications network.

Each of these segments plays a role in the network, but they differ significantly in their functions, design, and requirements. This article focuses on the telecom access network, exploring its unique characteristics, how it stands apart from metro and core networks, and the specific requirements for transceivers that distinguish it from other segments of the telecom network.

The Access Network Explained

The telecom access network is the critical link between end-users and the broader telecommunications network. It is the segment of the network that extends from the telecom service provider’s central office to the individual subscribers, whether they be residential homes, businesses, or mobile users. The primary function of the access network is to provide a direct pathway for users to access telecommunications services such as the Internet, telephone, and television.

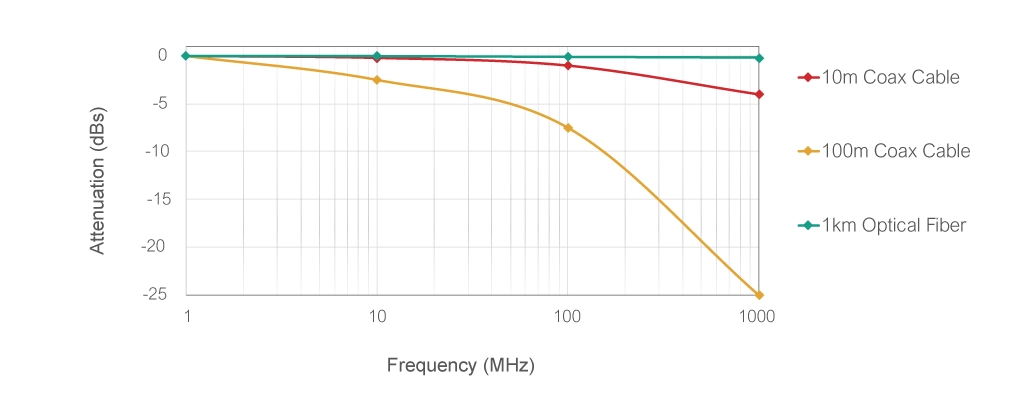

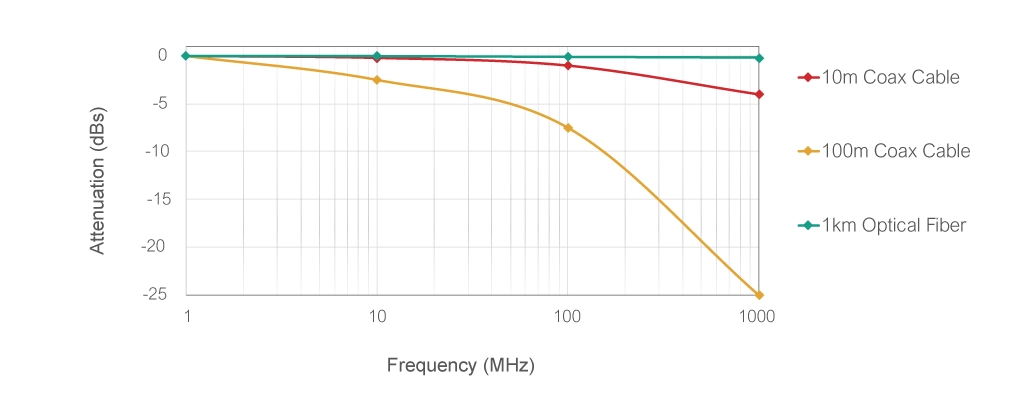

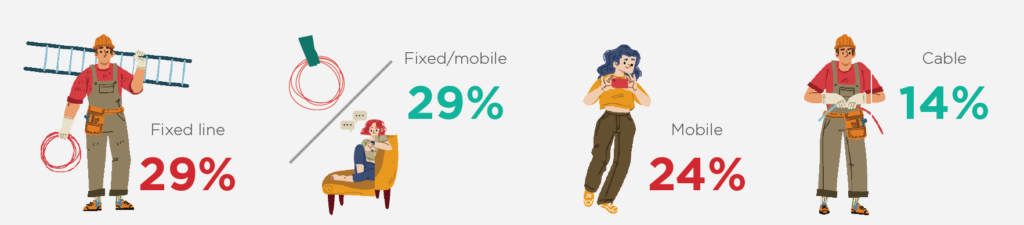

The access network is characterized by its proximity to end-users and its focus on reaching as many subscribers as possible. It encompasses various technologies, including copper wires (DSL), fiber optics (FTTH, FTTB), coaxial cables, and wireless connections (Wi-Fi, cellular networks), each tailored to different service requirements and deployment scenarios.

The Requirements of the Access vs Core and Metro Networks

The distinction between the access network and the other sections of a telecom network, namely the metro and core networks, lies primarily in their operational focus and scale. The core network handles the highest volume of data, employing advanced technologies and high-capacity infrastructure to ensure seamless data transmission across great distances. The metro network is designed to handle a higher capacity than the access network because it consolidates traffic from many users. The access network segment is characterized by its vast and dispersed nature, aimed at covering as much geographical area as possible to connect a large number of subscribers

Metro and core networks are engineered for high capacity and long distance to manage the vast amounts of data traversing the global telecommunications infrastructure. They employ sophisticated routing, switching, and multiplexing technologies to optimize data flow and ensure reliability and quality of service over long distances. In contrast, the access network prioritizes accessibility, flexibility, and cost-effectiveness, aiming to deliver services to as many users as possible with varying bandwidth requirements.

What Do Transceivers in the Access Network Need?

Transceivers, devices that combine transmission and reception capabilities in a single unit, are critical components of all sections of a telecom network. However, the requirements for transceivers in the access network differ significantly from those in the metro and core networks.

- Range and Power Consumption: Access network transceivers often operate over shorter distances than their metro and core counterparts. They are designed to be power-efficient to support a dense deployment of endpoints with varying ranges.

- Flexibility and Scalability: Given the diverse technologies and deployment scenarios within the access network, transceivers must be highly flexible and scalable. This flexibility allows service providers to upgrade network capabilities or adapt to new standards without significant infrastructure overhaul.

- Cost Sensitivity: Cost is a critical factor in the access network due to the need to deploy a vast number of transceivers to connect individual subscribers.

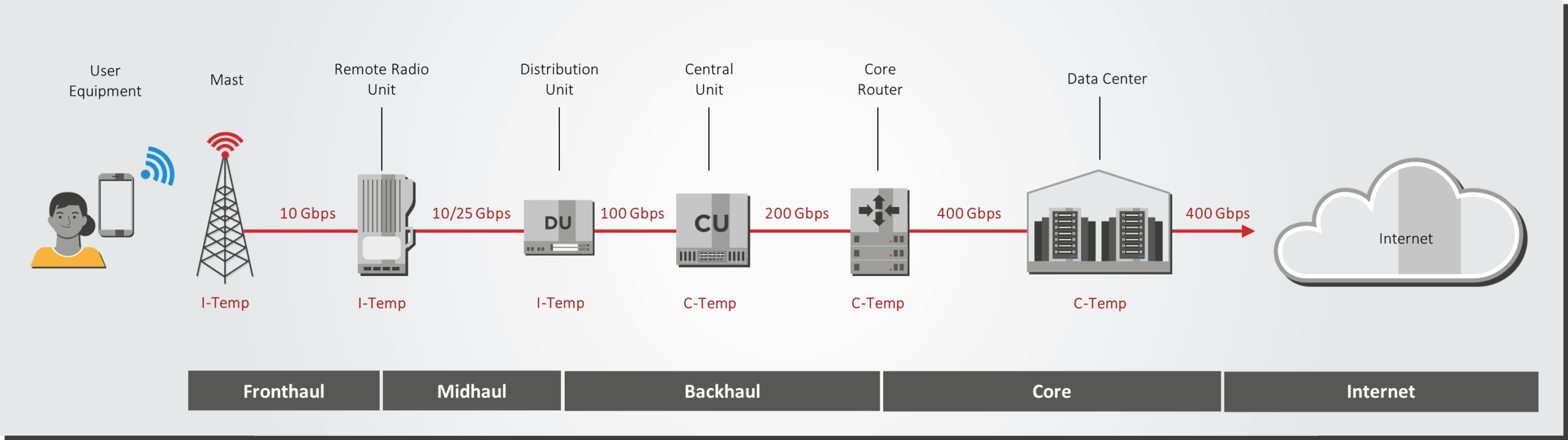

- Environmental Robustness: Access network transceivers are often subjected to harsher environmental conditions than those deployed in controlled environments like data centers or network hubs. They will often have industrial temperature (I-temp) ratings.

Takeaways

The telecom access network connects end-users to the vast world of telecommunications services, distinguishing itself from the metro and core networks through its focus on accessibility and subscriber reach. The access network demands specific solutions for transceiver components, such as shorter rangers, lower power consumption and capacity, lower costs, and industrial hardening.

Tags: access network, businesses, central office, coaxial cables, copper wires, core network, Data transmission, EFFECT Photonics, end-users, fiber optics, high-speed, Internet, long-distance, metro network, mobile users, network architectures, residential homes, service requirements, telecom service provider, telecommunications services, telephone, television, The evolution of telecommunications, wireless connections

What’s New Inside a 100G ZR Module?

In the optical access networks, the 400ZR pluggables that have become mainstream in datacom applications…

In the optical access networks, the 400ZR pluggables that have become mainstream in datacom applications are too expensive and power-hungry. Therefore, operators are strongly interested in 100G pluggables that can house coherent optics in compact form factors, just like 400ZR pluggables do. The industry is labeling these pluggables as 100ZR.

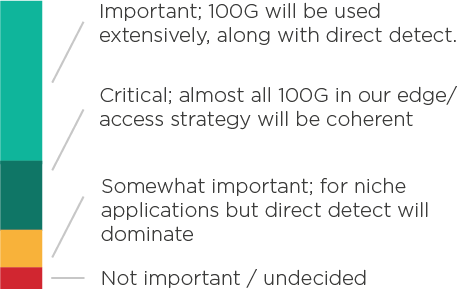

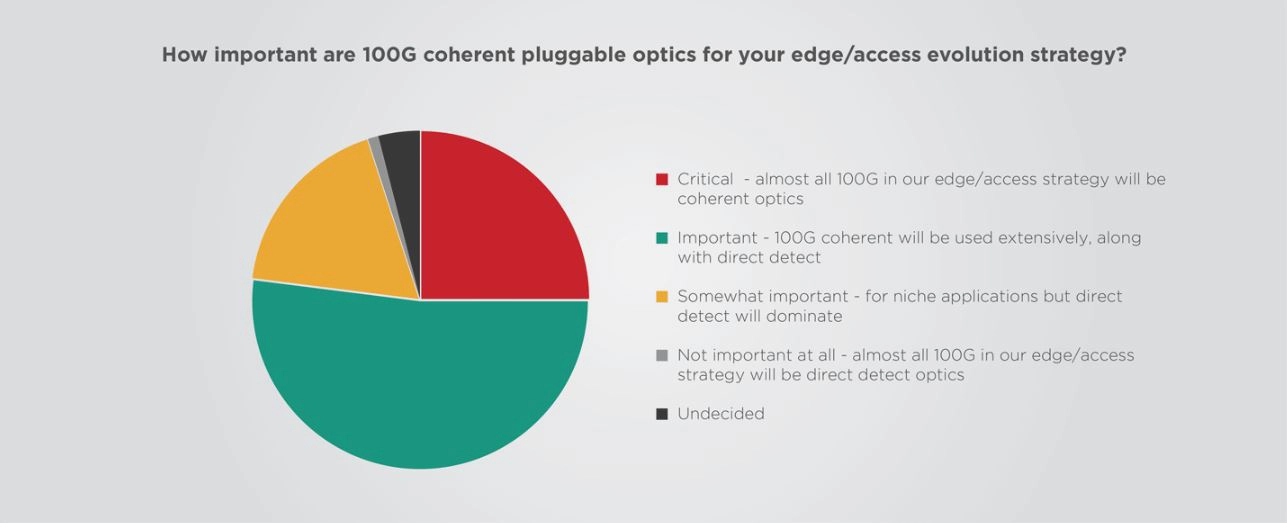

A recently released Heavy Reading survey revealed that over 75% of operators surveyed believe that 100G coherent pluggable optics will be used extensively in their edge and access evolution strategy. However, this interest had yet to materialize into a 100ZR market because no affordable or power-efficient products were available. The most the industry could offer was 400ZR pluggables that were “powered-down” for 100G capacity.

By embracing smaller and more customizable light sources, new optimized DSP designs, and high-volume manufacturing capabilities, we can develop native 100ZR solutions with lower costs that better fit edge and access networks.

Smaller Tunable Lasers

Since the telecom and datacom industries want to pack more and more transceivers on a single router faceplate, integrable tunable laser assemblies (ITLAs) must maintain performance while moving to smaller footprints and lower power consumption and cost.

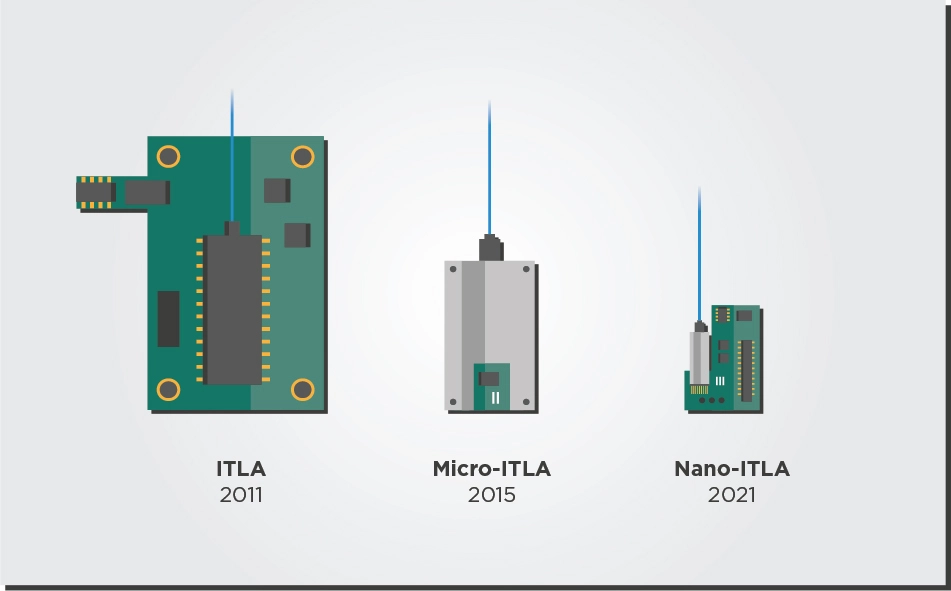

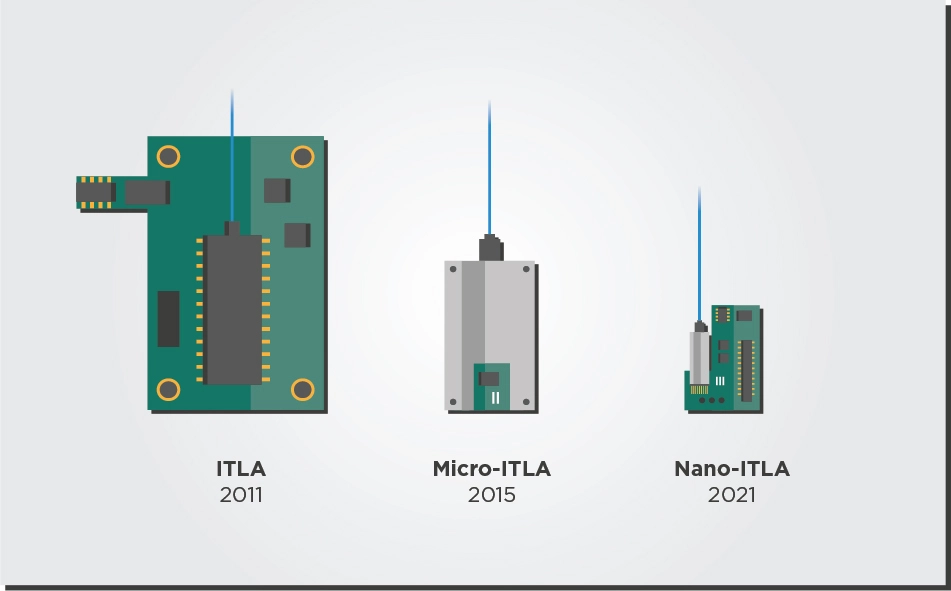

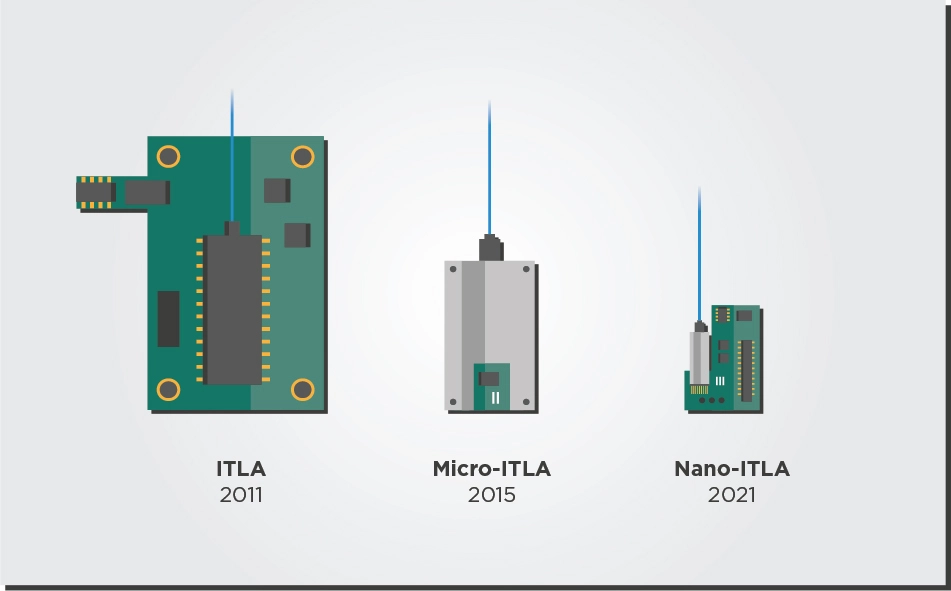

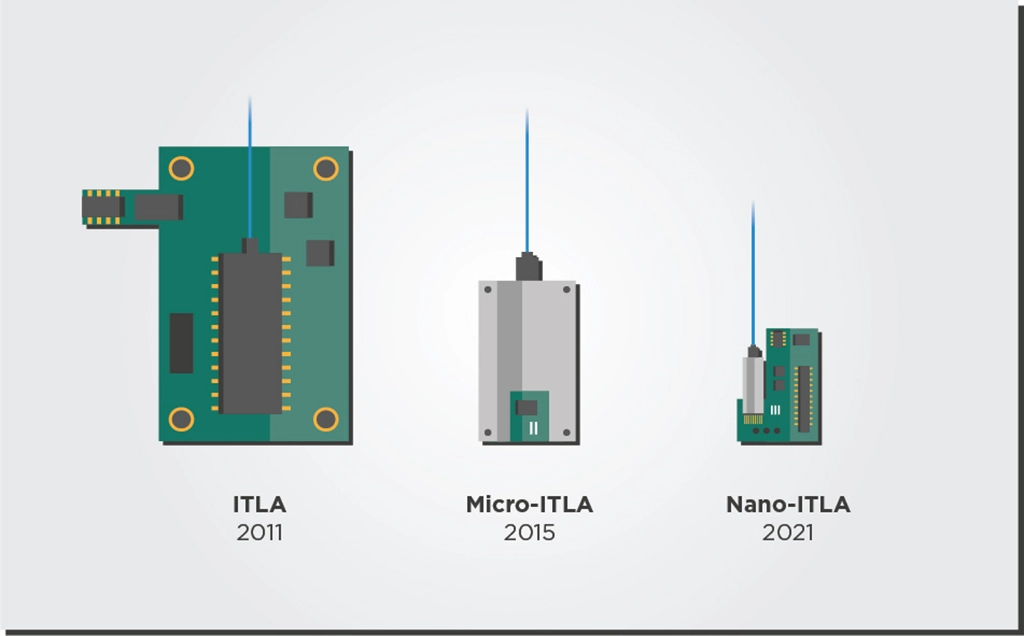

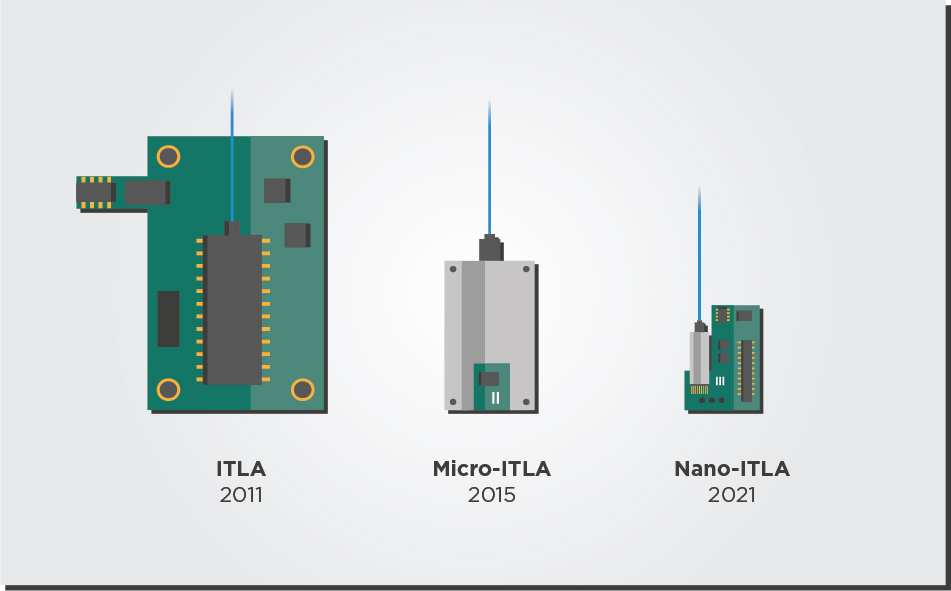

Fortunately, such ambitious specifications became possible thanks to improved photonic integration technology. The original 2011 ITLA standard from the Optical Internetworking Forum (OIF) was 74mm long by 30.5mm wide. By 2015, most tunable lasers shipped in a OIF form factor that cut the original ITLA footprint in half. In 2021, the nano-ITLA form factor designed for QSFP-DD and OSFP modules had once again cut the micro-ITLA footprint almost in half.

There are still plenty of discussions over the future of ITLA packaging to fit the QSFP28 form factors of these new 100ZR transceivers. EFFECT Photonics has developed a solution that monolithically integrates all tunable laser functions (including the wavelength locker) into a novel pico-ITLA (pITLA) module that will become the world’s smallest ITLA for coherent applications. The pITLA is the next step in tunable laser integration, including all laser functions in a package with just 20% of the volume of a nano-ITLA module. The figure below shows that even a standard matchstick dwarves the pITLA in size.

More Efficient DSPs

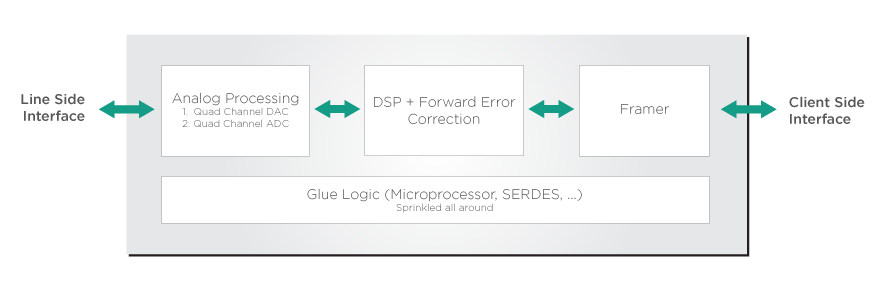

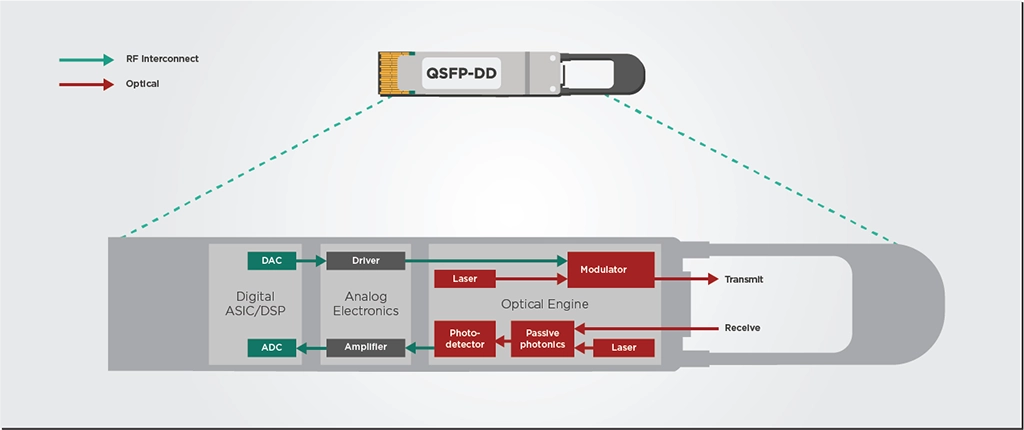

The 5 Watt-power requirement of 100ZR in a QSFP28 form factor is significantly reduced compared to the 15-Watt specification of 400ZR transceivers in a QSFP-DD form factor. Achieving this reduction requires a digital signal processor (DSP) specifically optimized for the 100G transceiver.

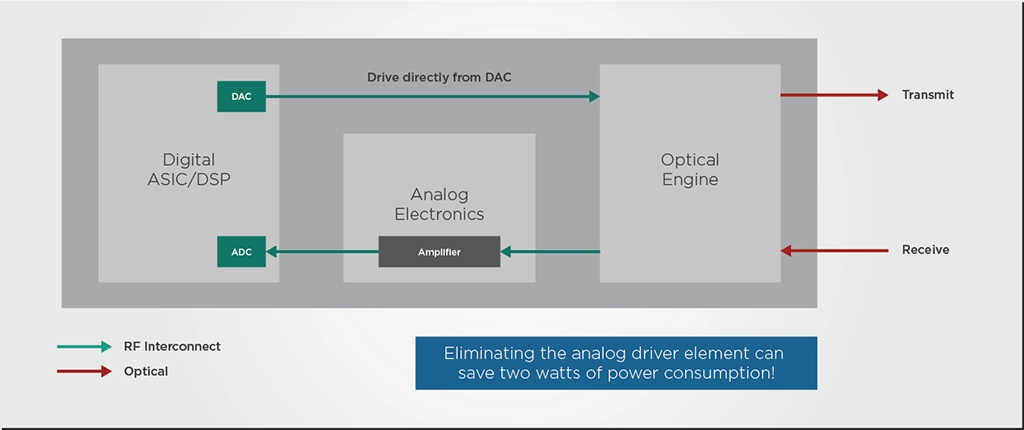

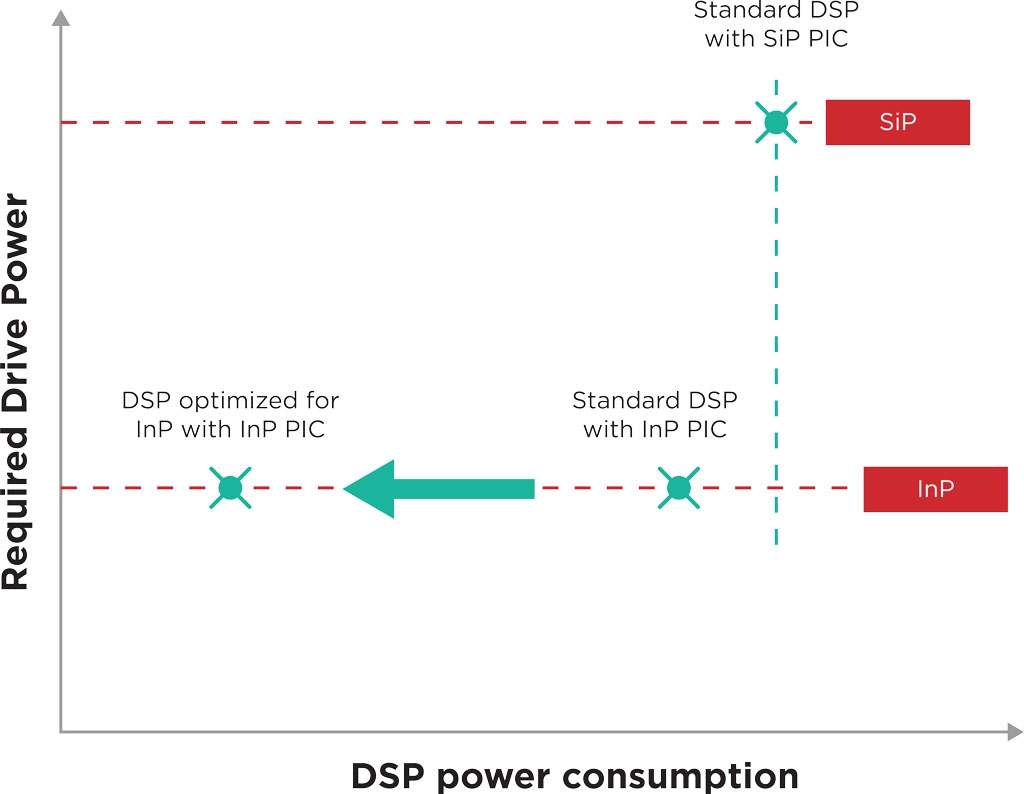

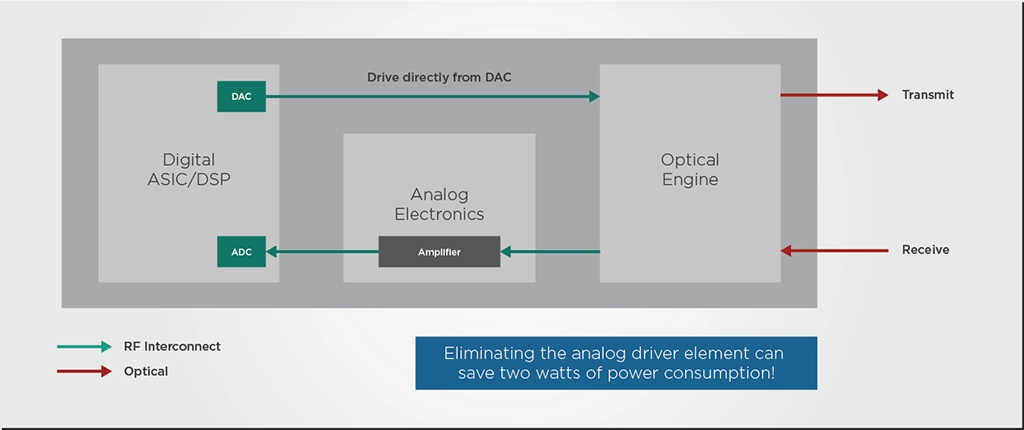

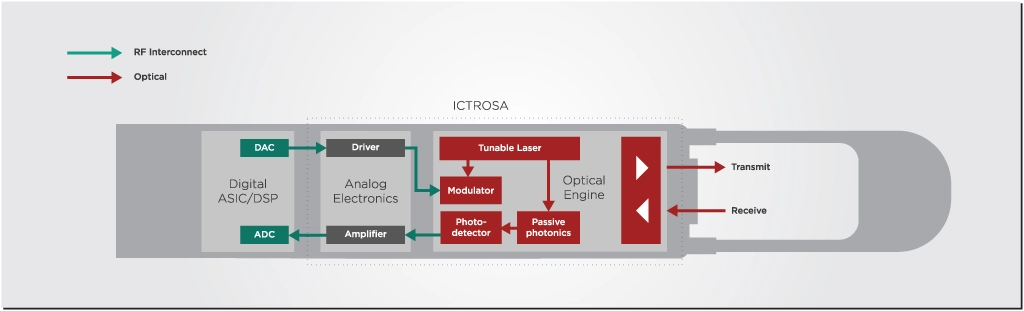

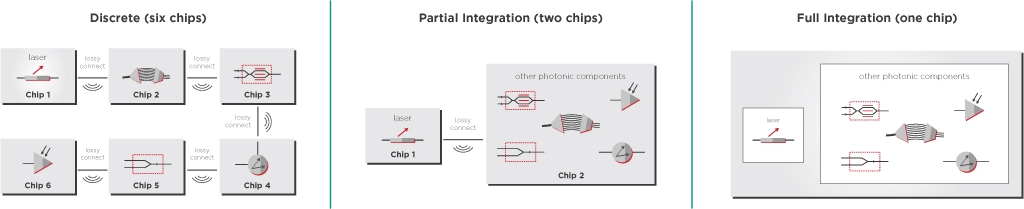

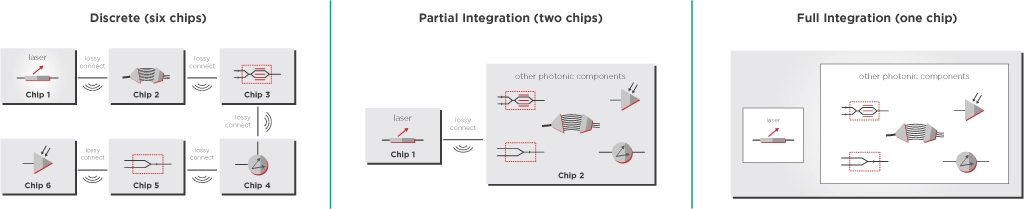

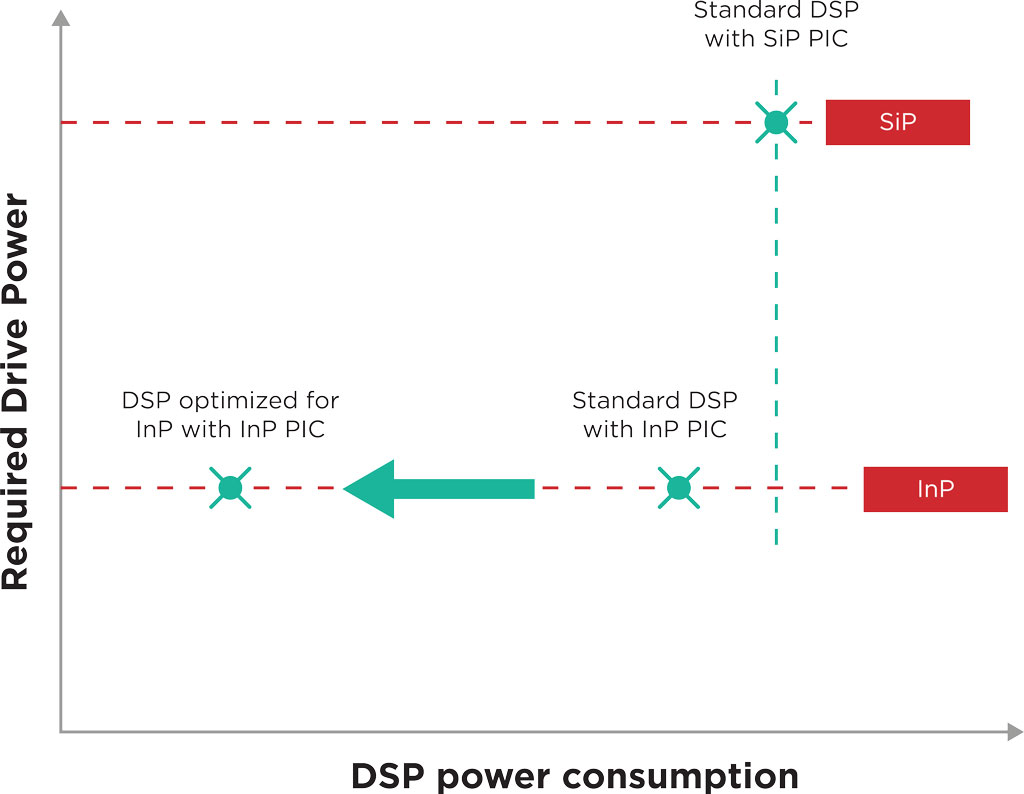

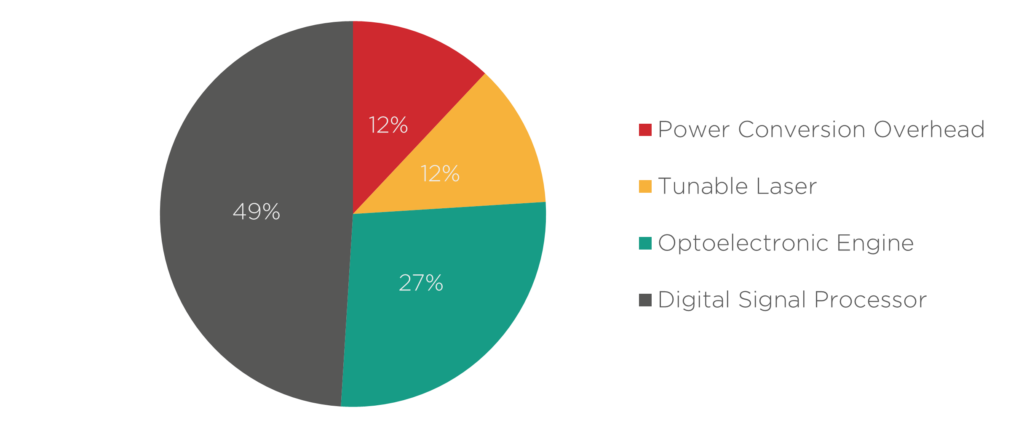

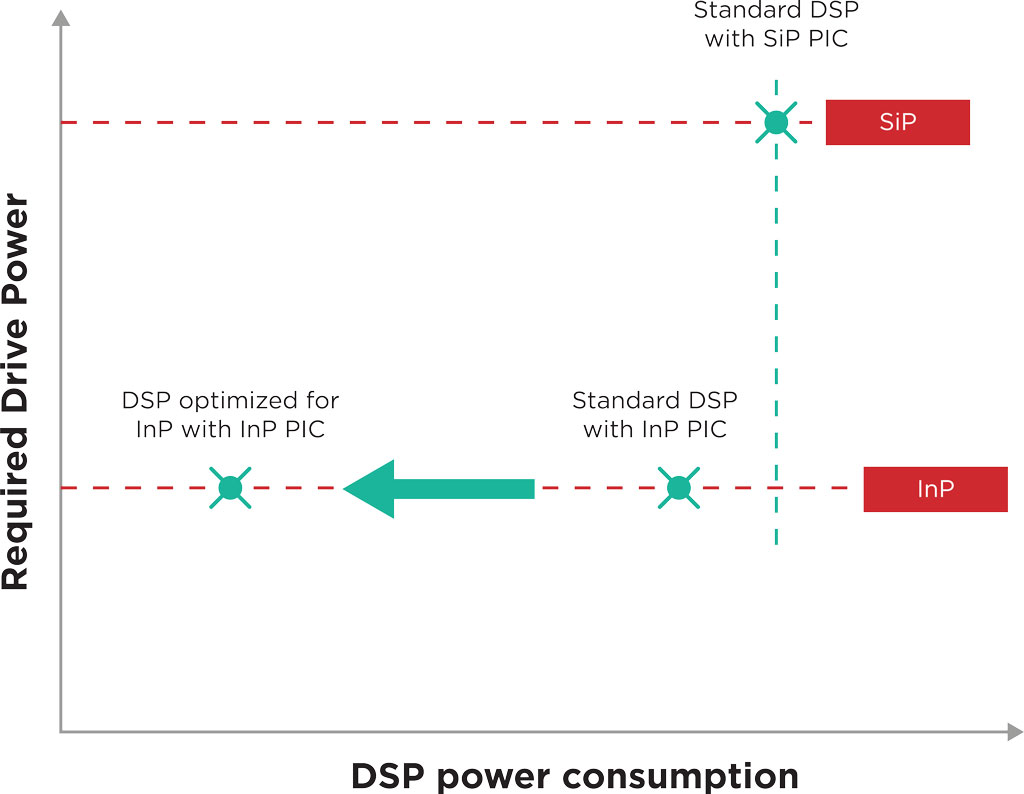

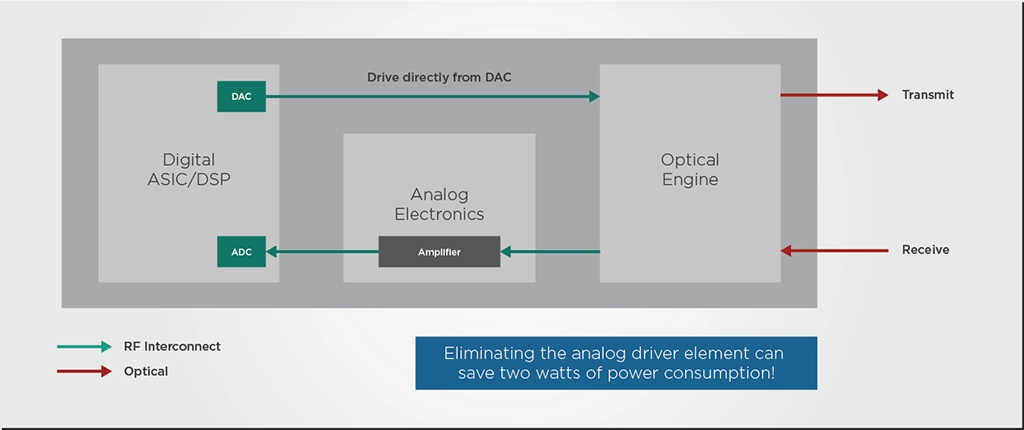

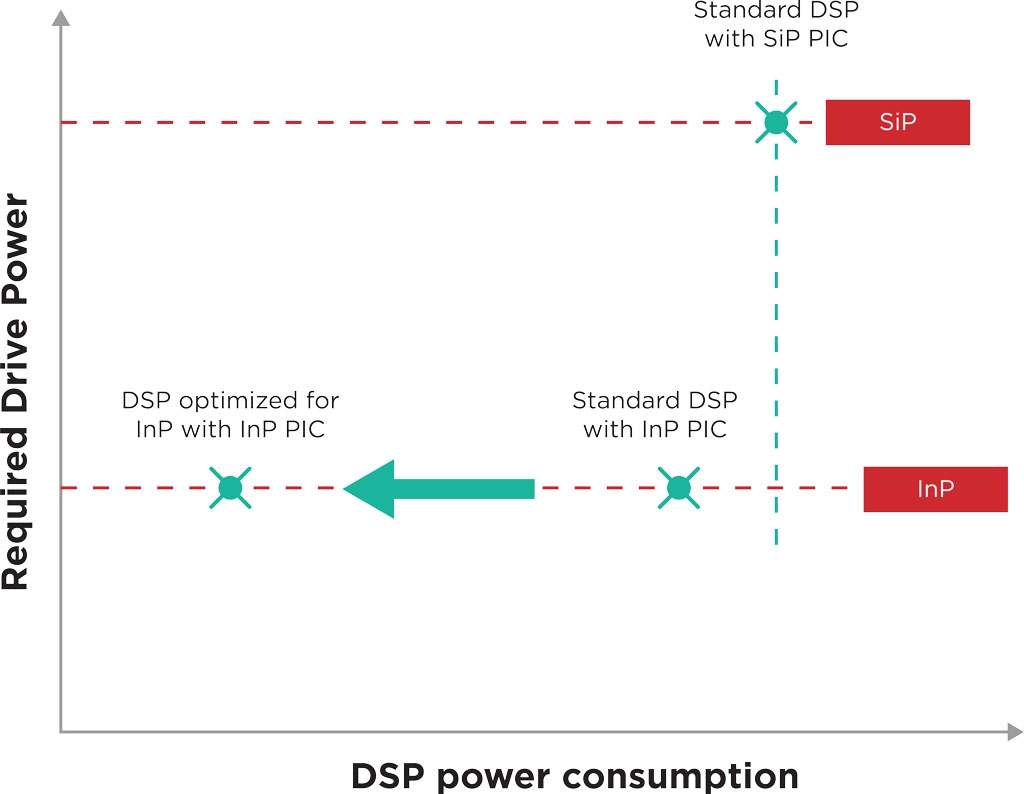

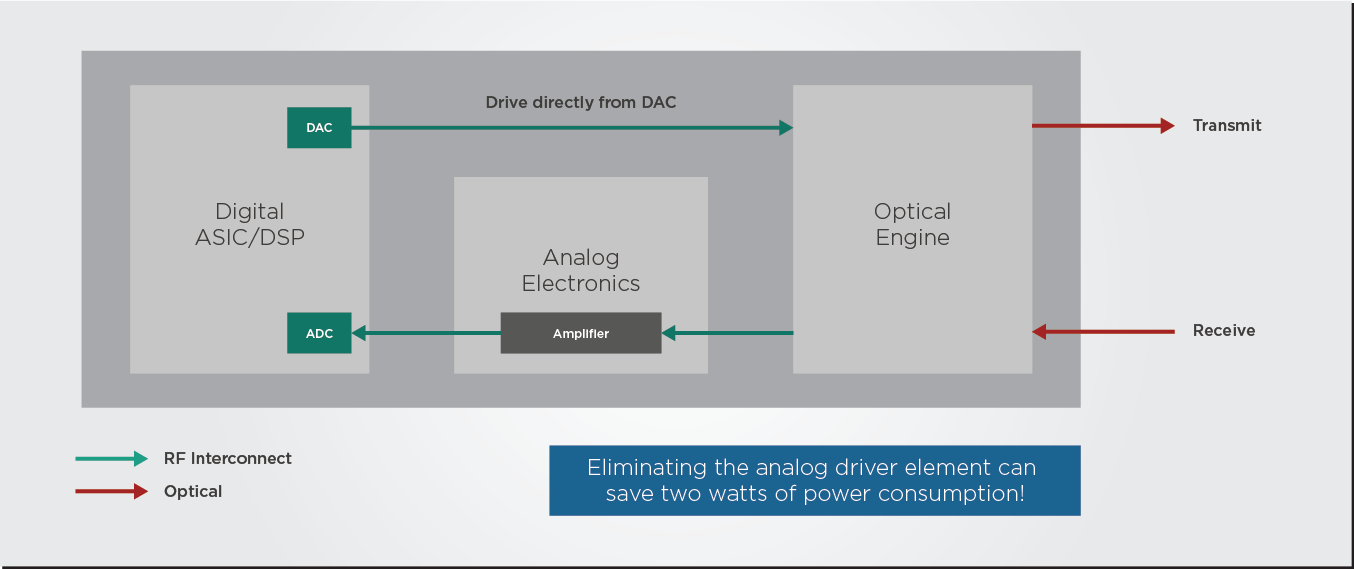

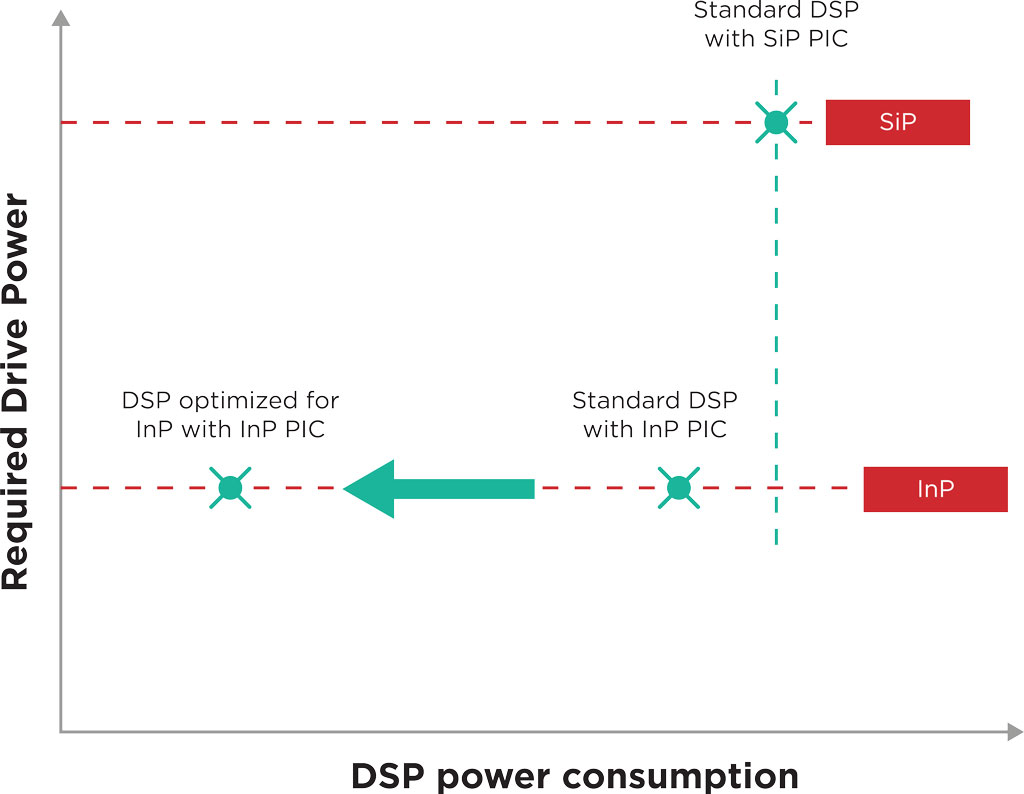

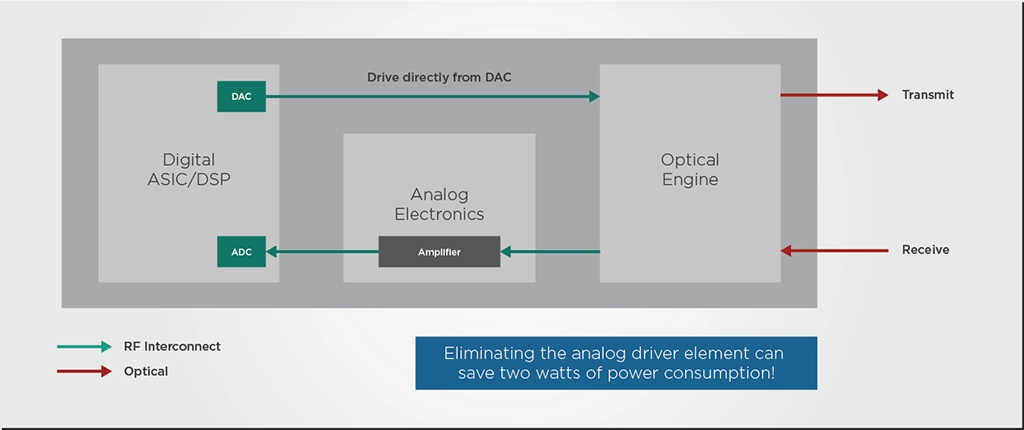

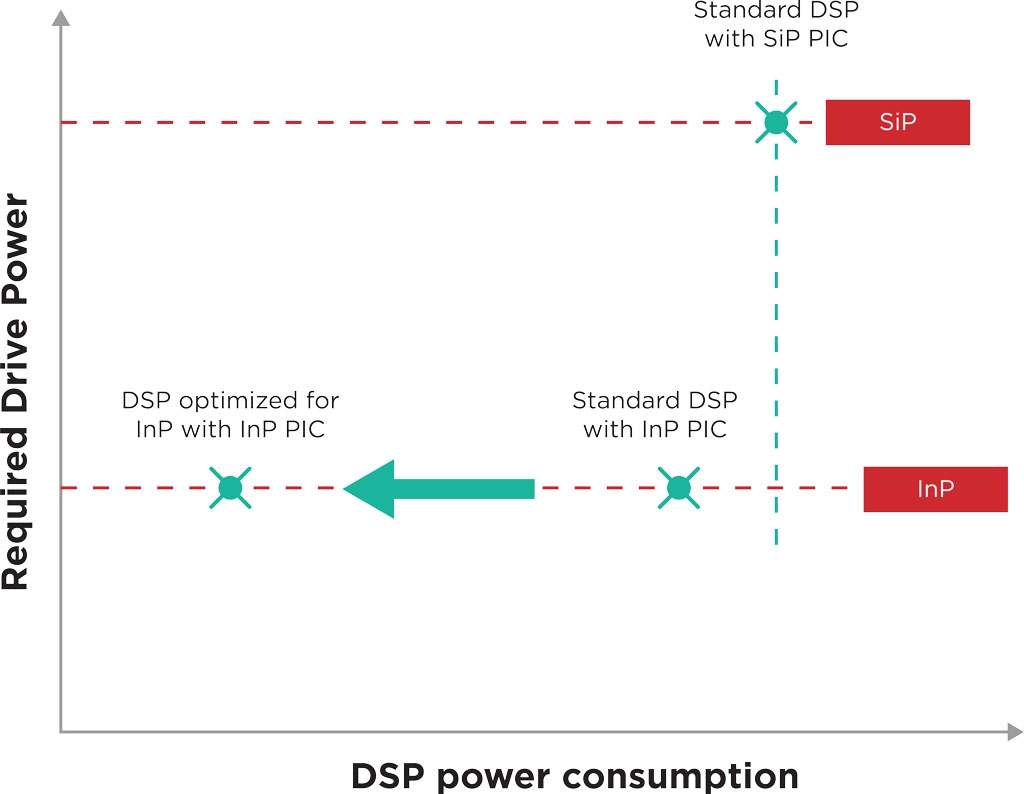

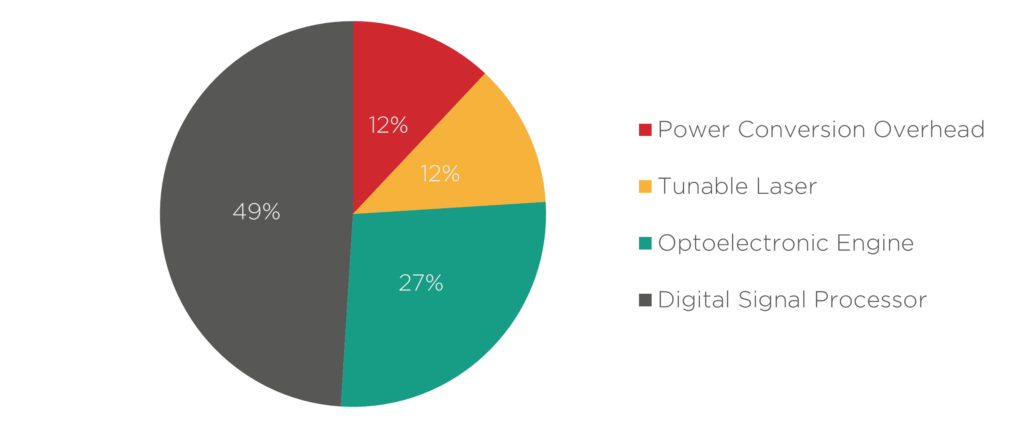

Current DSPs are designed to be agnostic to the material platform of the photonic integrated circuit (PIC) they are connected to, which can be Indium Phosphide (InP) or Silicon. Thus, they do not exploit the intrinsic advantages of these material platforms. Co-designing the DSP chip alongside the PIC can lead to a much better fit between these components.

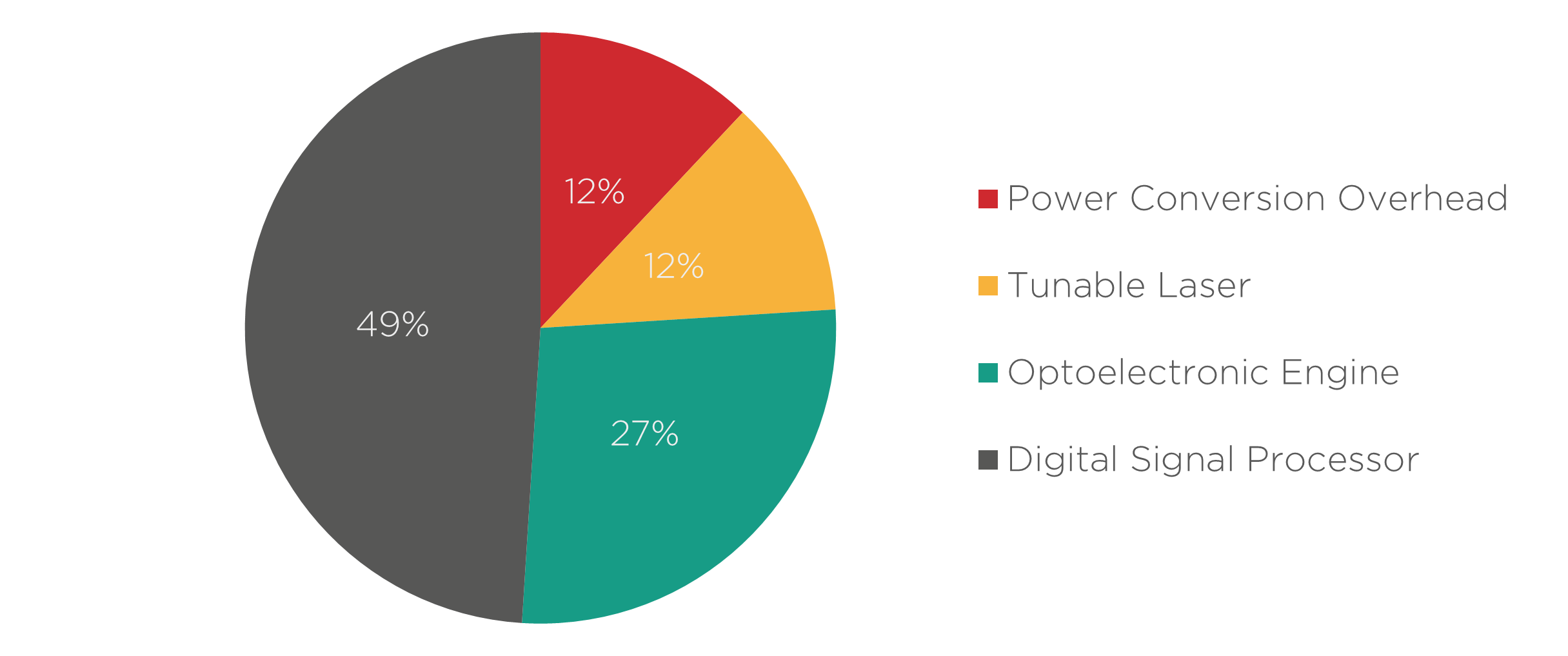

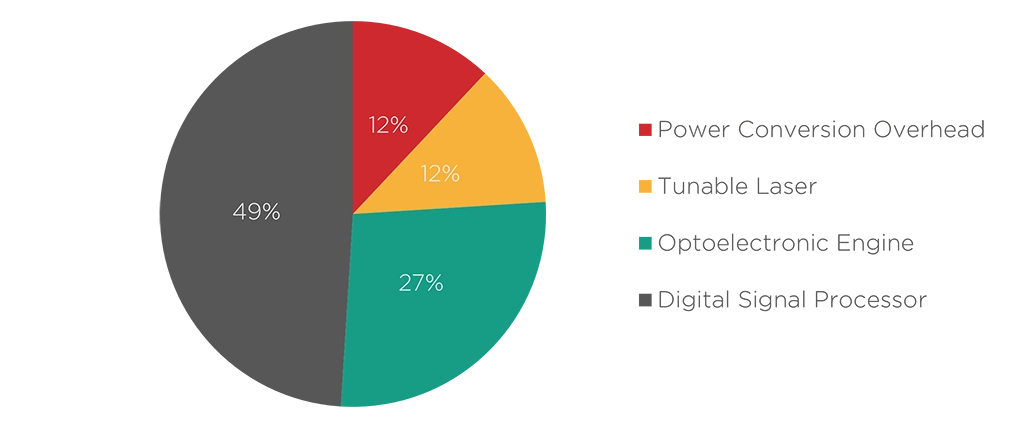

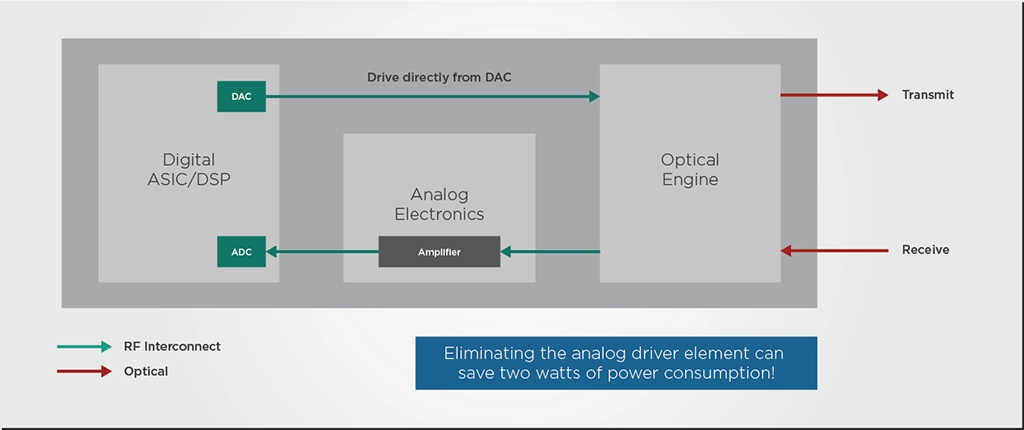

To illustrate the impact of co-designing PIC and DSP, let’s look at an example. A PIC and a standard platform-agnostic DSP typically operate with signals of differing intensities, so they need some RF analog electronic components to “talk” to each other. This signal power conversion overhead constitutes roughly 2-3 Watts or about 10-15% of transceiver power consumption.

If this InP PIC and the DSP are designed and optimized together instead of using a standard DSP, the PIC could be designed to run at a voltage compatible with the DSP’s signal output. This way, the optimized DSP could drive the PIC directly without needing the RF analog driver, doing away with most of the power conversion overhead we discussed previously.

Industrial Temperature Ranges

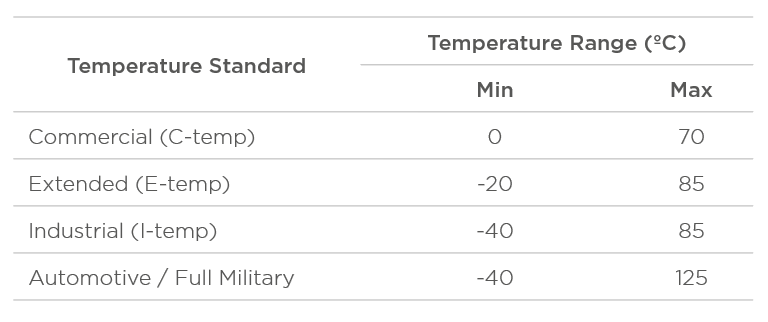

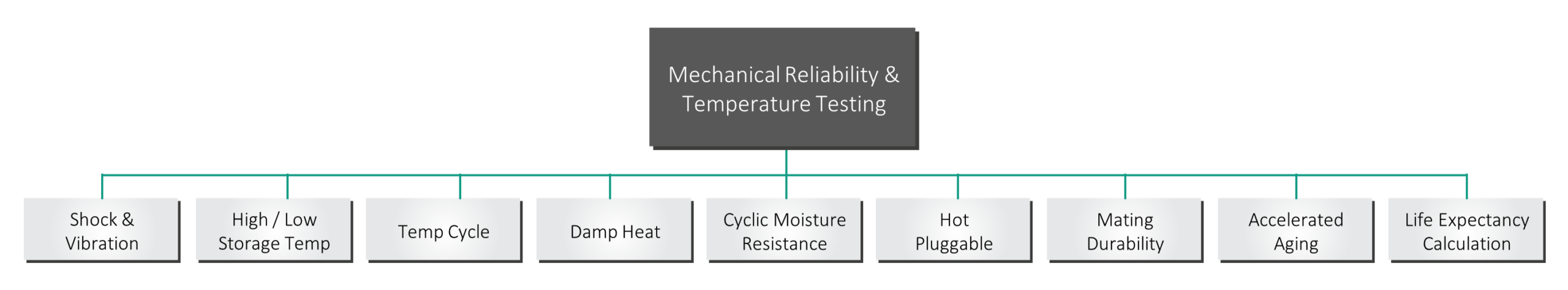

Traditionally, coherent devices have resided in the controlled settings of data center machine rooms or network provider equipment rooms. These rooms have active temperature control, cooling systems, dust and particle filters, airlocks, and humidity control. In such a setting, pluggable transceivers must operate within the so-called commercial temperature range (c-temp) from 0 to 70ºC.

On the other hand, the network edge often involves uncontrolled settings outdoors at the whims of Mother Nature. It might be at the top of an antenna, on mountain ranges, within traffic tunnels, or in Northern Europe’s severe winters. For these outdoor settings, transceivers should operate in the industrial temperature range (I-temp) from -40 to 85ºC. Higher altitude deployments provide additional challenges too. Because the air gets thinner, networking equipment cooling mechanisms become less effective, and the device cannot withstand casing temperatures as high as they can at sea level.

Making an I-temp transceiver means that every internal component—lasers, optical engine, DSP—must also be I-temp compliant. Thus, it’s essential to specifically design laser sub-assemblies and DSPs that can reliably work within the I-temp range.

Takeaways

The advent of 100G ZR modules addresses the industry’s need for more affordable and energy-efficient alternatives to implement coherent technologies in access networks. The drive towards miniaturization, exemplified by EFFECT Photonics’ development of the world’s smallest ITLA module, alongside DSP optimizations that minimize power conversion overhead, will help develop pluggables that meet the efficiency and footprint requirements of access networks. Furthermore, it’s necessary for these modules to operate across an I-temp range that can handle a variety of challenging environments in which these networks must operate.

These developments will help operators lay the groundwork for a new generation of coherent optical access networks.

Tags: 100G ZR, access networks, coherent optics, Cost-effective solutions, Datacom applications, DSP optimization, Edge evolution, efficiency, energy consumption, Environmental challenges, Industrial temperature range, ITLA modules, miniaturization, network operators, Networking equipment, Optical Access Networks., Photonics, Photonics Integration, pluggables, Technology advancements, tunable lasers

Tunable Lasers and DSPs in the Age of AI

The use of generative artificial intelligence (AI) models is transforming several industries, and data centers…

The use of generative artificial intelligence (AI) models is transforming several industries, and data centers are no exception. AI models are computationally heavy, and their increasing complexity will require faster and more efficient interconnections than ever between GPUs, nodes, server racks, and data center campuses. These interconnects will have a major impact on the ability of data center architectures to scale and handle the demands of AI models in a sustainable way.

As we discussed in a previous article, transceivers that fit this new AI era must be fast, smart, and adapt to multiple use cases and conditions. However, what impact will that have on the tunable lasers and digital signal processors (DSPs) inside these transceivers? This article will review a couple of trends in lasers and DSPs to adapt to this new era.

The Power of Laser Arrays

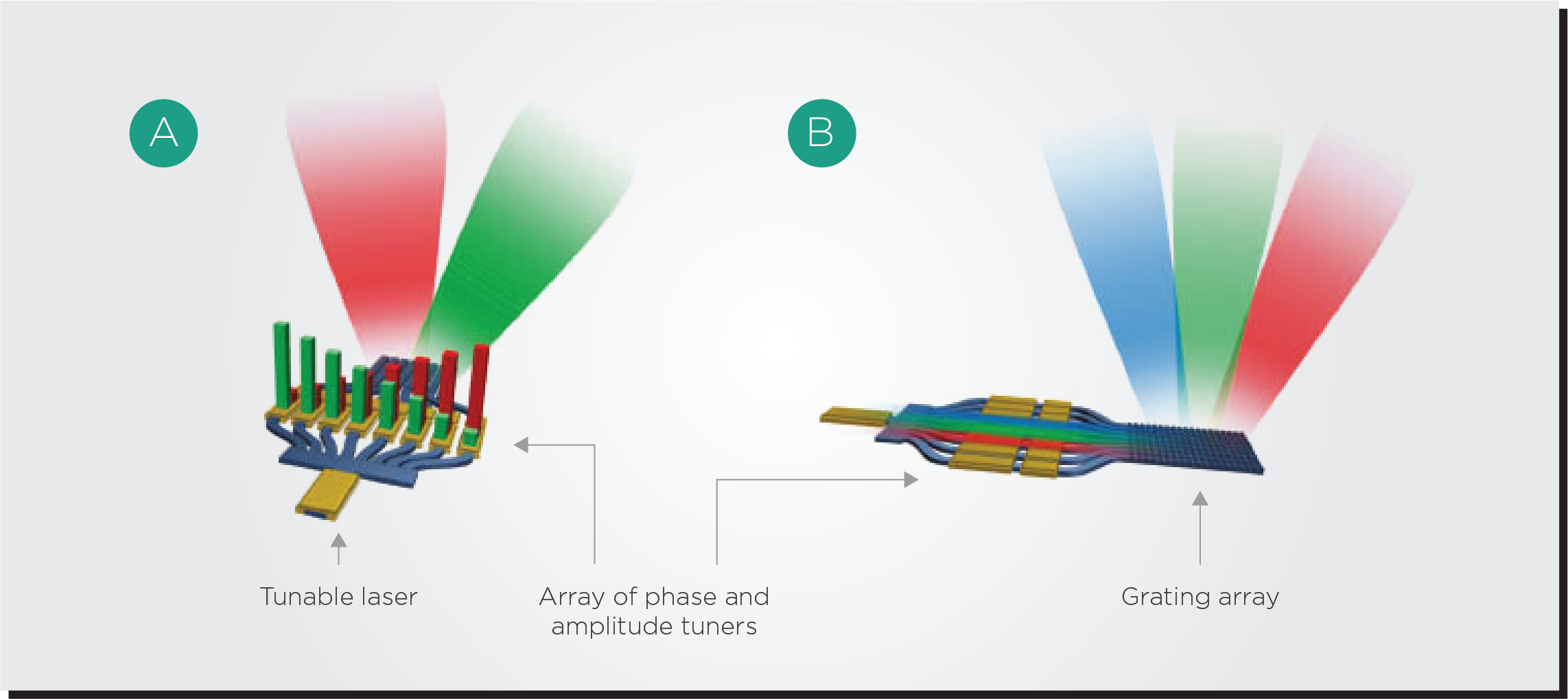

In 2022, Intel Labs demonstrated an eight-wavelength laser array fully integrated on a silicon wafer. These milestones are essential for optical transceivers because the laser arrays can allow for multi-channel transceivers that are more cost-effective when scaling up to higher speeds.

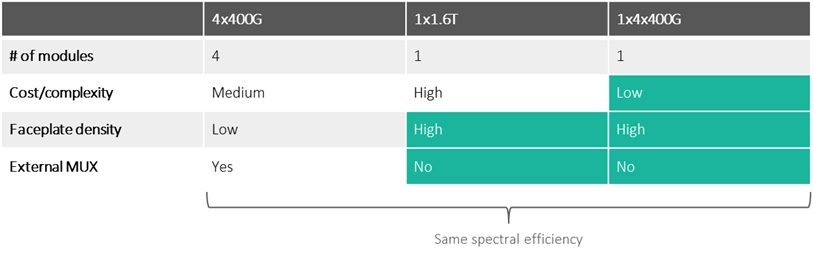

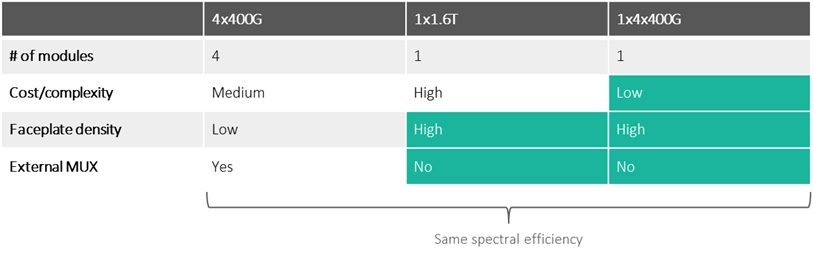

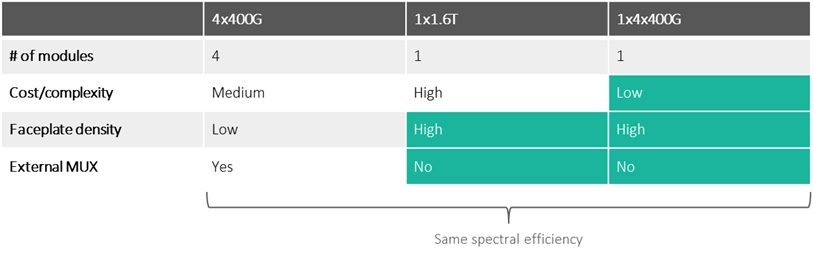

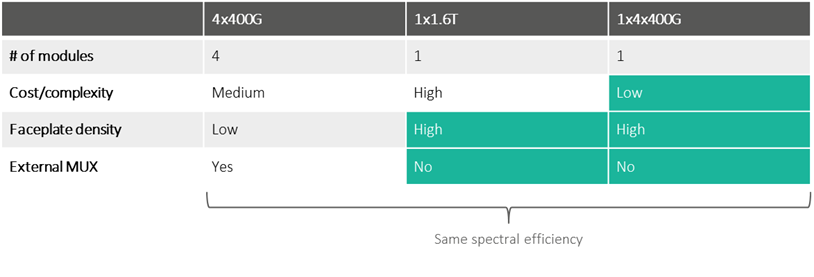

Let’s say we need an intra-DCI link with 1.6 Terabits/s of capacity. There are three ways we could implement it:

- Four modules of 400G: This solution uses existing off-the-shelf modules but has the largest footprint. It requires four slots in the router faceplate and an external multiplexer to merge these into a single 1.6T channel.

- One module of 1.6T: This solution will not require the external multiplexer and occupies just one plug slot on the router faceplate. However, making a single-channel 1.6T device has the highest complexity and cost.