Transceivers in the Time of TowerCos

A recent report from the International Telecommunications Union (ITU) declared that 37% of the global population still lacks internet access due to infrastructure deficits. In this context, Tower Companies (TowerCos) will be crucial in expanding network coverage, particularly in underserved areas.

Tower Companies (TowerCos) are entities specializing in managing “passive” mobile infrastructure. In other words, they manage everything that is not active equipment that emits a mobile signal. The TowerCo’s primary role is to host telecommunications antennas for multiple operators, facilitating more efficient mobile deployments. This concept allows telecom operators to focus on active network management while TowerCos handles the maintenance, access, and security of passive infrastructures like towers and power supplies.

Historically, telecom companies managed every aspect of their service delivery, including the ownership of towers. However, increasing capital expenditure costs and the need for rapid expansion in network coverage have motivated operators to outsource this infrastructure to TowerCos. In this way, operators can reduce the required capital expenditure on infrastructure and move that into their operating costs

The increasing bandwidth demands of 5G networks and data centers, prompted by new Internet-of-Things and artificial intelligence use cases, have further solidified the importance of TowerCos. A 2018 McKinsey study reported that the migration to 5G could double the total cost of ownership of a telecommunications company’s infrastructure by 2020 to 2025.

To adapt to this fast expansion of TowerCos worldwide, optical transceiver developers should consider what are the key requirements for products that will go into TowerCo infrastructure. In this article, EFFECT Photonics would like to highlight three of them: integration, remote diagnostics and management, and industrial hardening.

Integration for Compactness and Power Efficiency

Space and energy efficiency are critical for TowerCo infrastructure because they want to accommodate telecom equipment from multiple operators on the same structure. Greater photonics integration will be key to reducing the footprint of transceivers and other optical telecom equipment, as well as improving their power efficiency.

In many electronic and photonic devices, the interconnections between different components are often sources of losses and inefficiency. A more compact, integrated device will have shorter and more energy-efficient interconnections. Using an example from electronics, Apple’s system-on-chip processors fully integrate all electronic processing functions on a single chip. As shown in the table below, these processors are significantly more energy efficient than the previous generations of Apple processors.

| 𝗠𝗮𝗰 𝗠𝗶𝗻𝗶 𝗠𝗼𝗱𝗲𝗹 | 𝗣𝗼𝘄𝗲𝗿 𝗖𝗼𝗻𝘀𝘂𝗺𝗽𝘁𝗶𝗼𝗻 | |

| 𝗜𝗱𝗹𝗲 | 𝗠𝗮𝘅 | |

| 2023, M2 | 7 | 5 |

| 2020, M1 | 7 | 39 |

| 2018, Core i7 | 20 | 122 |

| 2014, Core i5 | 6 | 85 |

| 2010, Core 2 Duo | 10 | 85 |

| 2006, Core Solo or Duo | 23 | 110 |

| 2005, PowerPC G4 | 32 | 85 |

| Table 1: Comparing the power consumption of a Mac Mini with an M1 and M2 SoC chips to previous generations of Mac Minis. [Source: Apple’s website] | ||

The photonics industry can set a similar goal to Apple’s system-on-chip. By integrating all the optical components (lasers, detectors, modulators, etc.) on a single chip can minimize the losses and make devices such as optical transceivers more compact and efficient.

Remote Diagnostics and Management

Transceivers used in TowerCo infrastructures must also include advanced diagnostic and management features. These capabilities are essential for remote sites, enabling TowerCos and their telecom operators customers to monitor and manage their networks effectively.

For example, TowerCos and operators extensively use network function virtualization (NFV) capabilities. NFV allows operator customers to build their network on the shared infrastructure as well as determine and distribute their services. These technologies benefit greatly from smart transceivers that can be diagnosed and managed remotely from the NFV layer.

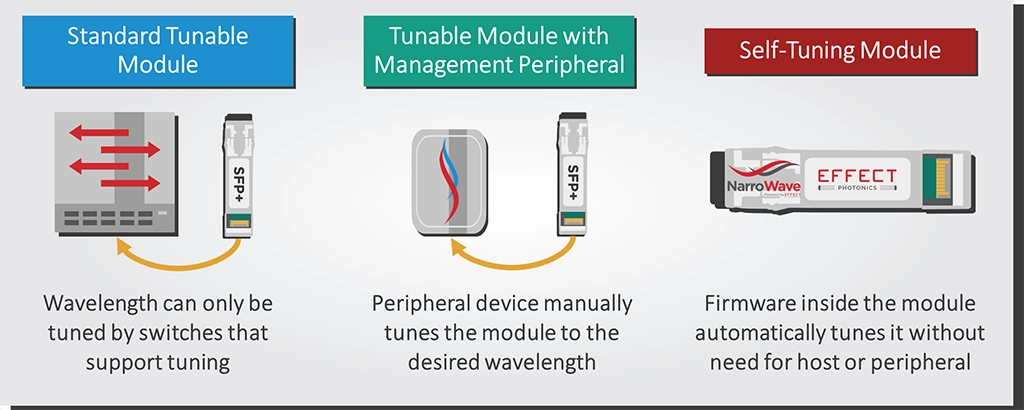

The concept of zero-touch provisioning becomes useful here. Transceivers can be pre-programmed by the central office for specific operational parameters, such as temperature, wavelength drift, dispersion, and signal-to-noise ratio. They can then be shipped to remote sites, where technicians just have to plug and play. This simplifies deployment for TowerCos.

Moreover, the same communication channels used for provisioning can also facilitate ongoing monitoring and diagnostics. This feature particularly benefits remote sites, where traditional maintenance methods like truck rolls are costly and inefficient. By remotely monitoring key metrics like transceiver temperature and power, TowerCos and operator customers can conduct health checks and manage their infrastructure more efficiently.

Industrial Hardening

Transceivers in TowerCo infrastructures must be designed to withstand harsh outdoor environments. The resilience of these components is critical for maintaining continuous network service and preventing downtime, especially in remote or challenging locations.

Commercial temperature (C-temp) transceivers are designed to operate from 0°C to 70°C. These transceivers suit the controlled environments of data center and network provider equipment rooms. These rooms have active temperature control, cooling systems, filters for dust and other particulates, airlocks, and humidity control. On the other hand, industrial temperature (I-temp) transceivers are designed to withstand more extreme temperature ranges, typically from -40°C to 85°C. These transceivers are essential for deployments in outdoor environments or locations with harsh operating conditions. It could be at the top of an antenna, on mountain ranges, inside traffic tunnels, or in the harsh winters of Northern Europe.

| 𝗧𝗲𝗺𝗽𝗲𝗿𝗮𝘁𝘂𝗿𝗲 𝗦𝘁𝗮𝗻𝗱𝗮𝗿𝗱 | 𝗧𝗲𝗺𝗽𝗲𝗿𝗮𝘁𝘂𝗿𝗲 𝗥𝗮𝗻𝗴𝗲 (°𝗖) | |

| 𝗠𝗶𝗻 | 𝗠𝗮𝘅 | |

| Commercial (C-temp) | 0 | 70 |

| Extended (E-temp) | -20 | 85 |

| Industrial (I-temp) | -40 | 85 |

| Automotive / Full Military | -40 | 125 |

| Table 2: Comparing the temperature ranges of different temperature hardening standards, including industrial and automotive/full military applications. | ||

Takeaways

TowerCos will be vital in expanding network coverage across the world and meeting the increasing demands of 5G networks. In this context, EFFECT Photonics believes that optical transceiver products that go into TowerCo infrastructure must meet the following key requirements

- Integration for compactness and power efficiency

- Advanced remote diagnostics and management features

- Industrial hardening for durability in harsh environments.

These aspects will be crucial for efficient, reliable, and cost-effective network deployment and maintenance and will support TowerCos in making optical connectivity more accessible worldwide.